Quick mould opening/closing control structure and control method of toggle type injection molding machine

A control structure, mold opening and closing technology, applied in the field of rapid mold opening and closing control structure, can solve the problems of increased energy consumption and use cost of the whole machine, deviation of mold opening stop position, large rigid impact, etc., so as to eliminate the large impact of template movement. , Accurate stop position, reduce the effect of rigid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

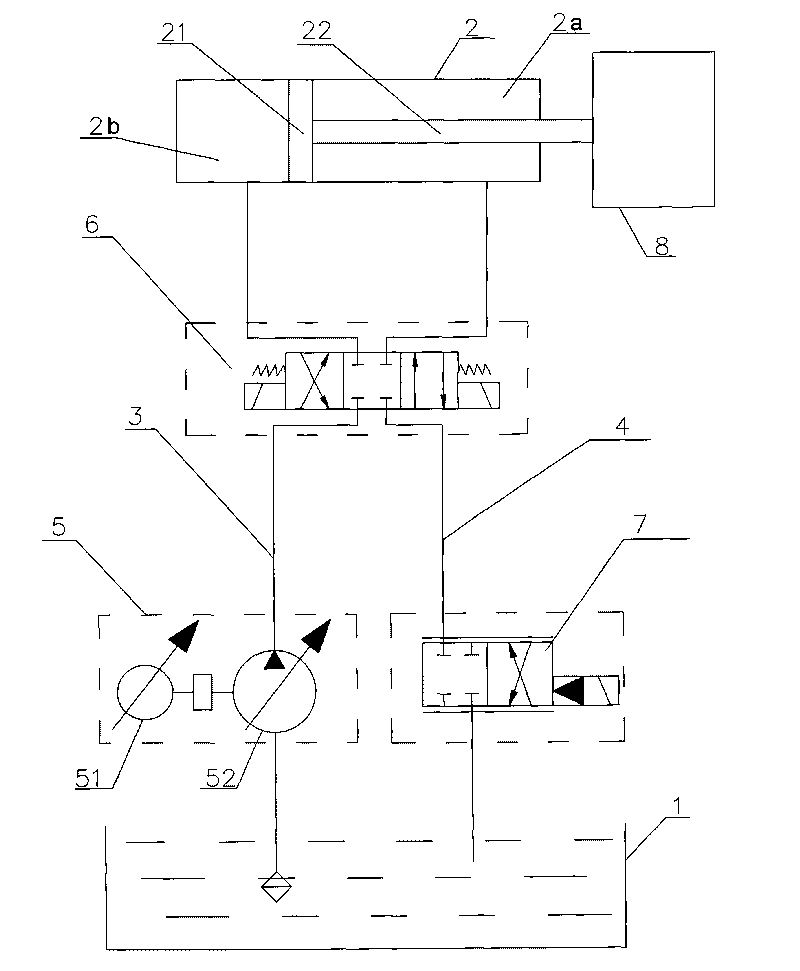

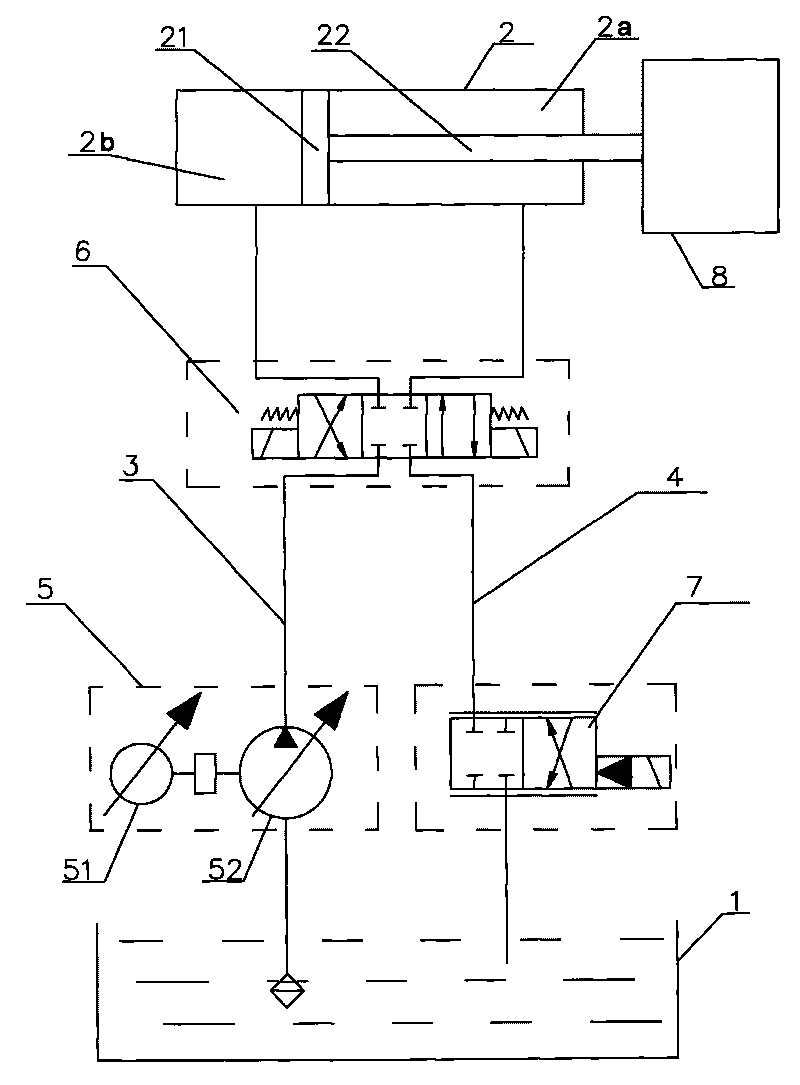

[0028] Such as figure 1As shown, the present invention is a quick mold opening and closing control structure for a toggle-type injection molding machine. 5. The directional control valve 6 and the proportional flow valve 7 with feedback are composed. The mold opening and closing hydraulic cylinder 2 is composed of the clamping piston 21, the clamping piston rod 22, the rod chamber 2a on the side of the clamping piston rod 22 and the other side The rodless cavity 2b is formed, the output end of the clamping piston rod 22 links the toggle lever 8 to open and close the mold, the main oil pipeline 3 connects the fuel supply tank 1 and the rodless cavity 2b, and the oil return pipeline 4 connects the fuel supply tank 1 with the The rod cavity 2a, the servo hydraulic drive device 5 is set in the main oil line 3, the proportional flow valve 7 is set in the oil return line 4, and the direction control valve 6 is set between the main oil line 3 and the oil return line 4 to control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com