Servo controller

A servo control device and learning control technology, which is applied in the direction of program control, digital control, thread cutting device, etc., can solve the problems of the deterioration of the servo characteristics of the rotating shaft, large synchronization errors, and failure to obtain learning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

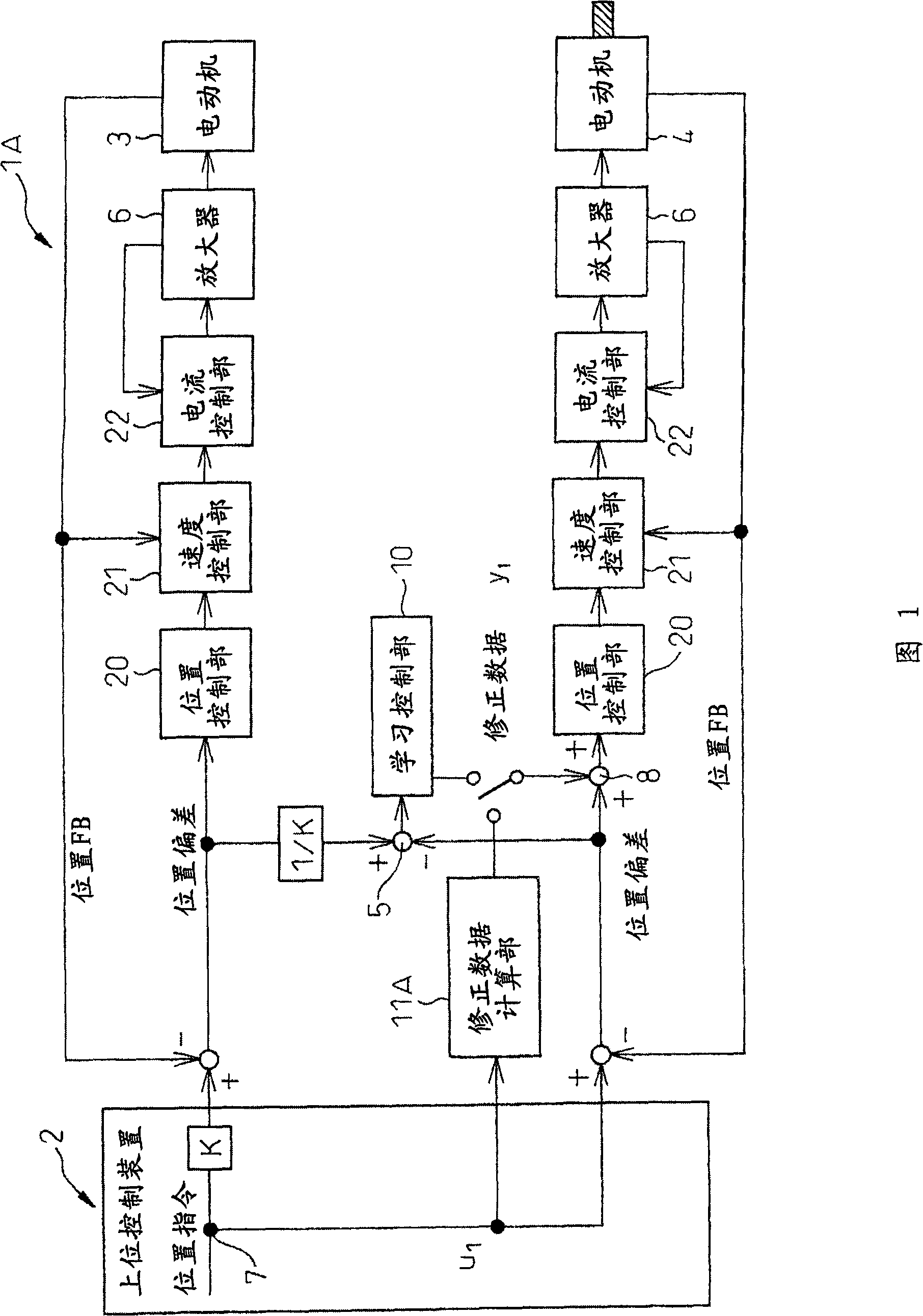

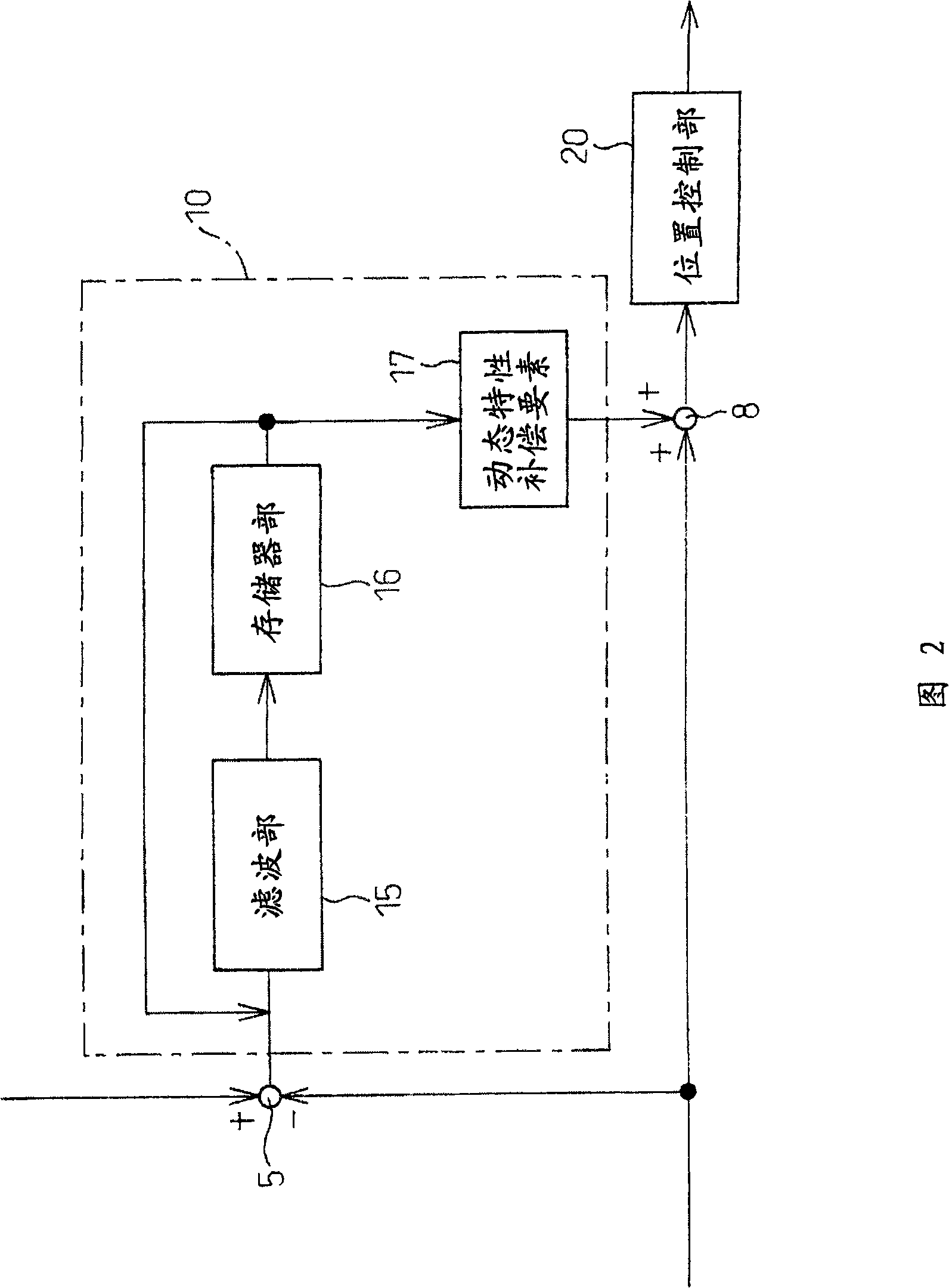

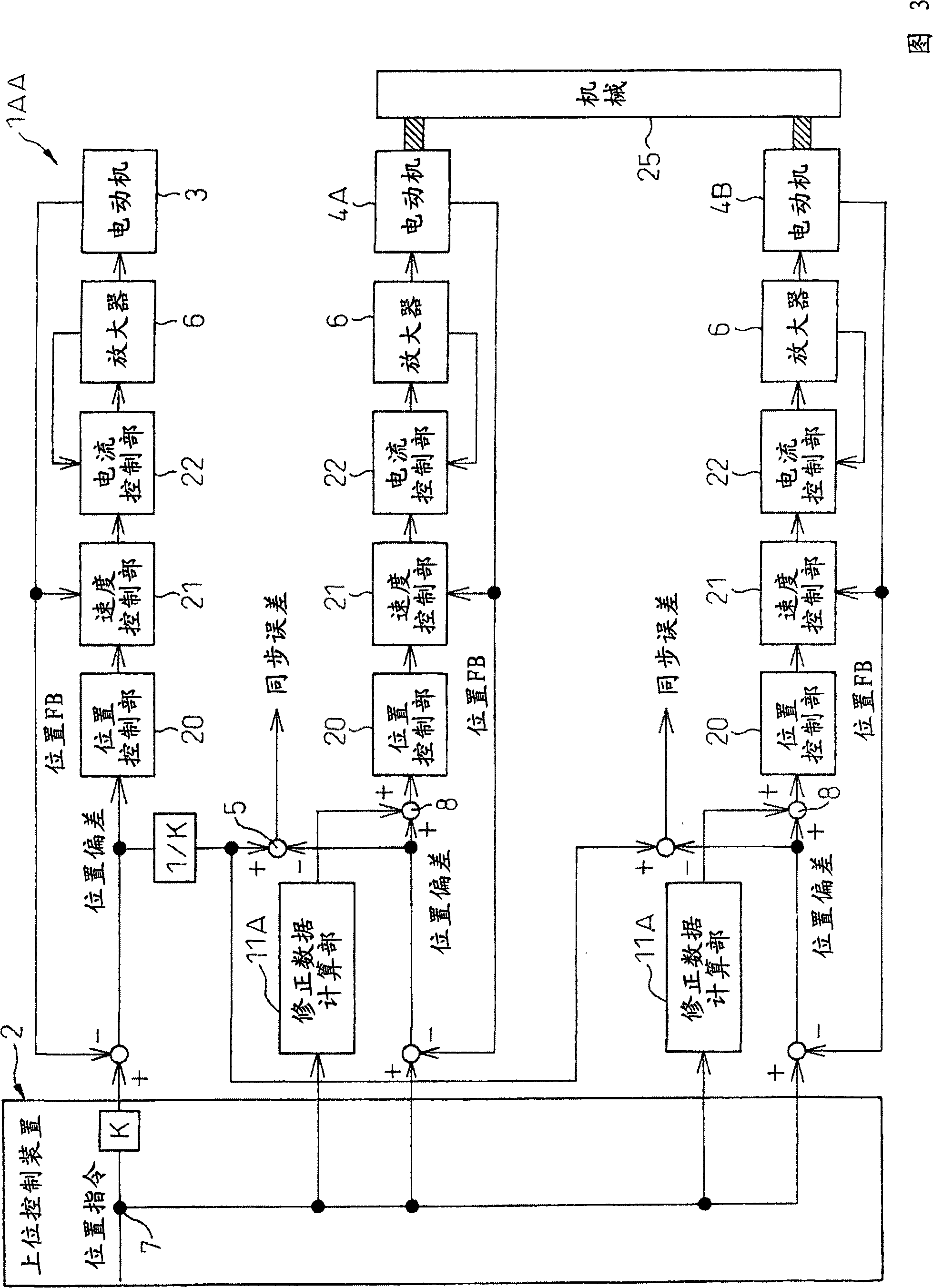

[0035] Hereinafter, specific examples of embodiments of the present invention will be described using the drawings. FIG. 1 is a block diagram of a first embodiment of the servo control device of the present invention. The servo control device 1A of the present embodiment is connected to the host control device 2 via a common memory not shown. The movement command value output from the host control device 2 is input to the servo control device, and the spindle motor (master servo motor) 3 that drives the machine tool spindle (master shaft) and the feed side that drives the slave shaft that performs direct motion are synchronously controlled. Command value of the servo motor (slave side servo motor) 4. The position deviation is obtained by subtracting the position feedback value from the position detector (not shown) from the position command value. The position detector is used to detect the position of the servo motors 3 and 4 and is installed in the servo motors 3 and 4 . O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com