High-precision hydraulic servo control system

A hydraulic servo and control system technology, applied to fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve problems such as unsatisfactory stability, low control efficiency, and unreachable control accuracy, and achieve Increased speed, improved positioning accuracy, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

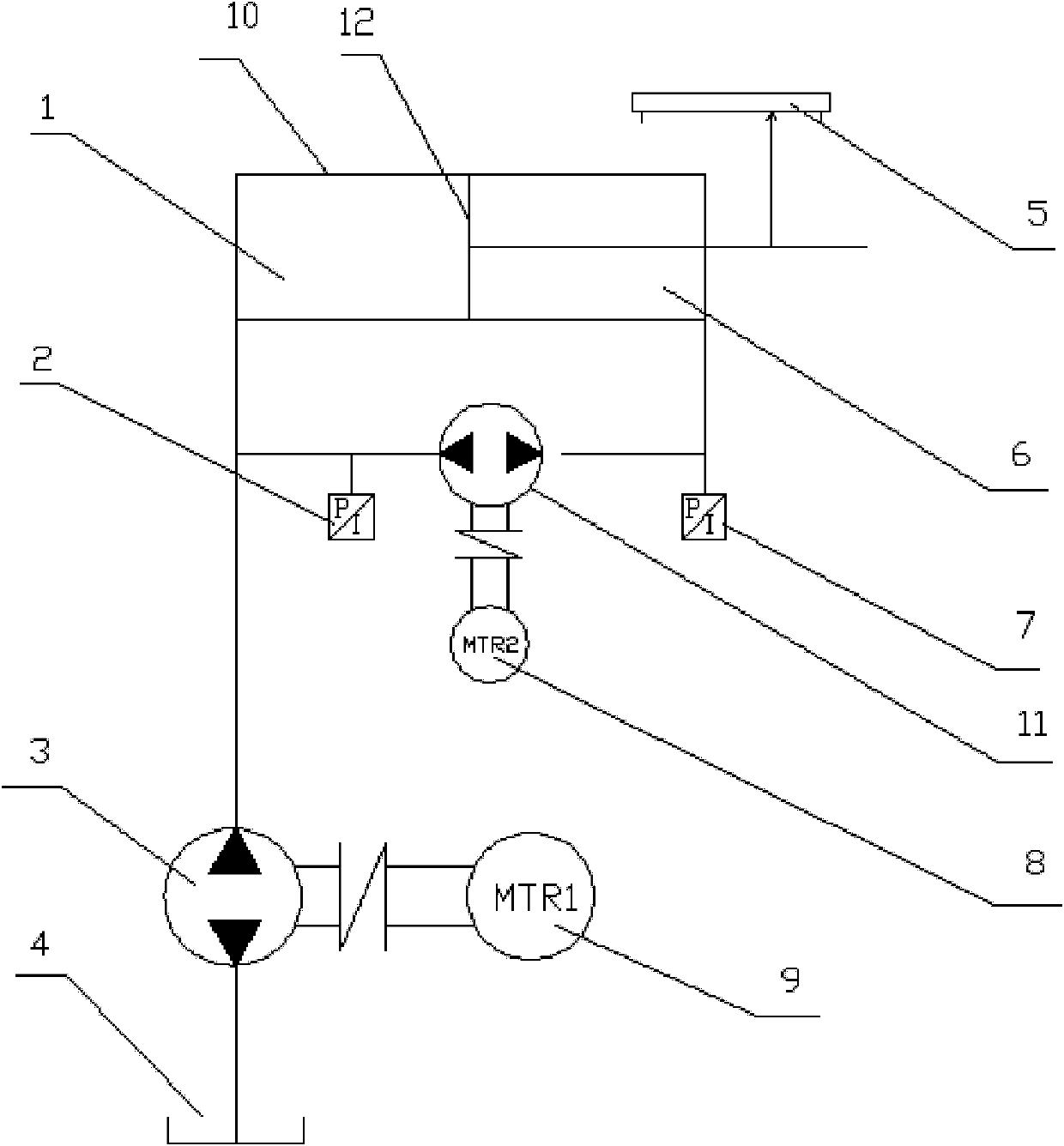

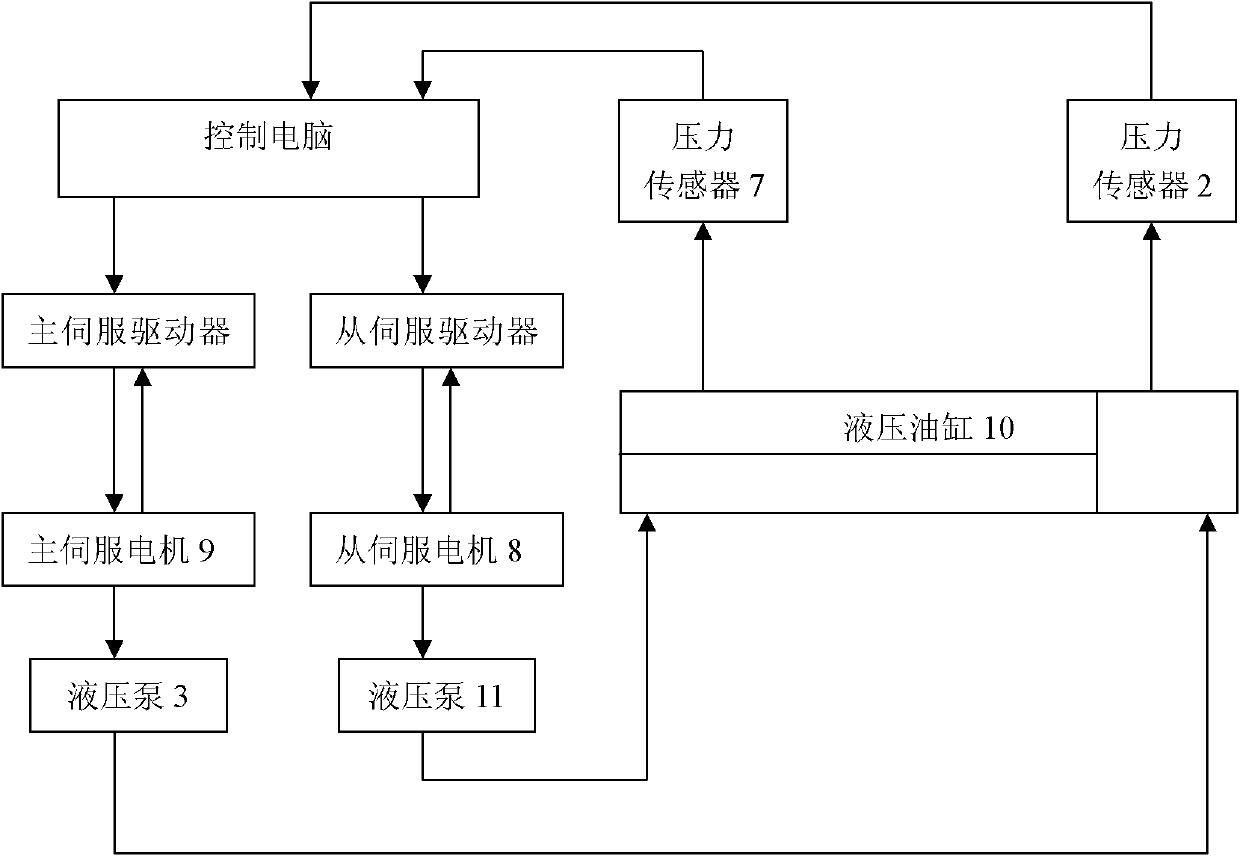

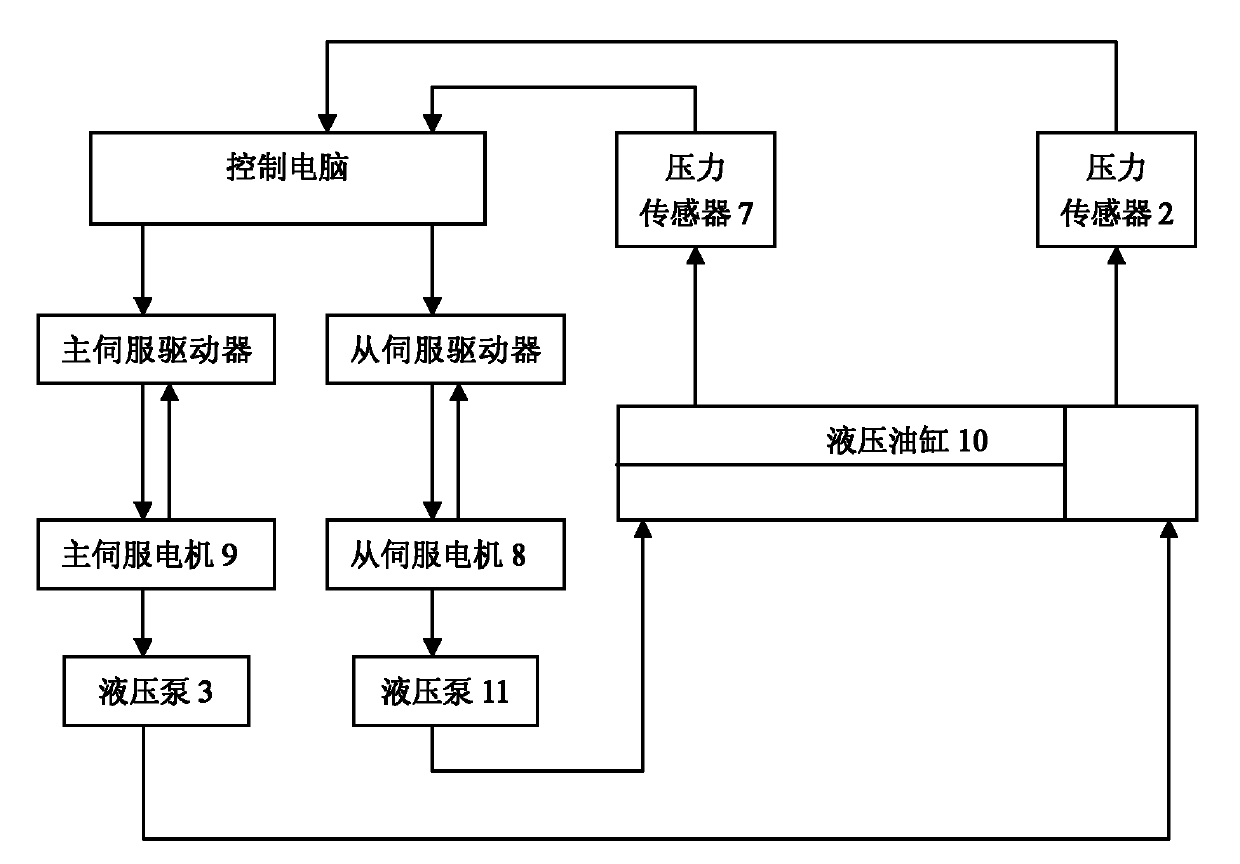

[0018] Such as figure 1 As shown, the piston 12 of the hydraulic cylinder 10 is fixedly connected with the sliding block of the position sensor 5 . The position sensor feeds back the position of the oil cylinder piston 12 to the control computer in real time. The pressure sensor 2 communicates with the rodless chamber of the hydraulic cylinder 10, and feeds back the pressure signal of the rodless chamber to the control computer. The pressure sensor 7 communicates with the rod chamber of the hydraulic cylinder 10, and feeds back the pressure signal of the rod chamber to the control computer. The main motor 9 is connected with the hydraulic pump 3, and the hydraulic pump 3 can absorb oil from the oil tank 4 through forward and reverse rotation, and output hydraulic oil with a certain pressure and flow rate to the oil cylinder 10, and can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com