Method for preparing one-dimensional ZnO/SnO2 core/shell structure nano heterojunction semiconductor material

A technology of core-shell structure and nanomaterials, applied in nanotechnology, nanotechnology, metal material coating technology, etc., can solve the problems of complex process and toxicity, and achieve high repeatability, good crystallinity and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

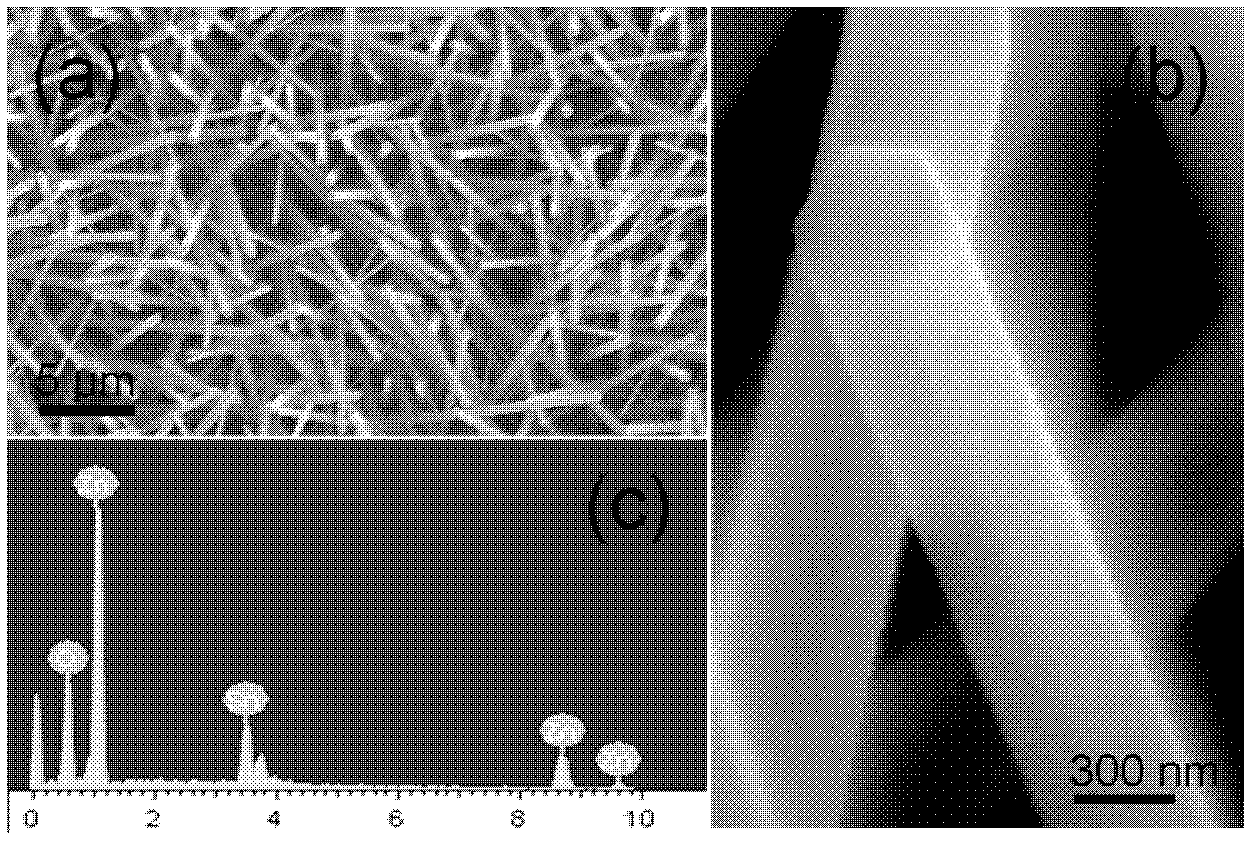

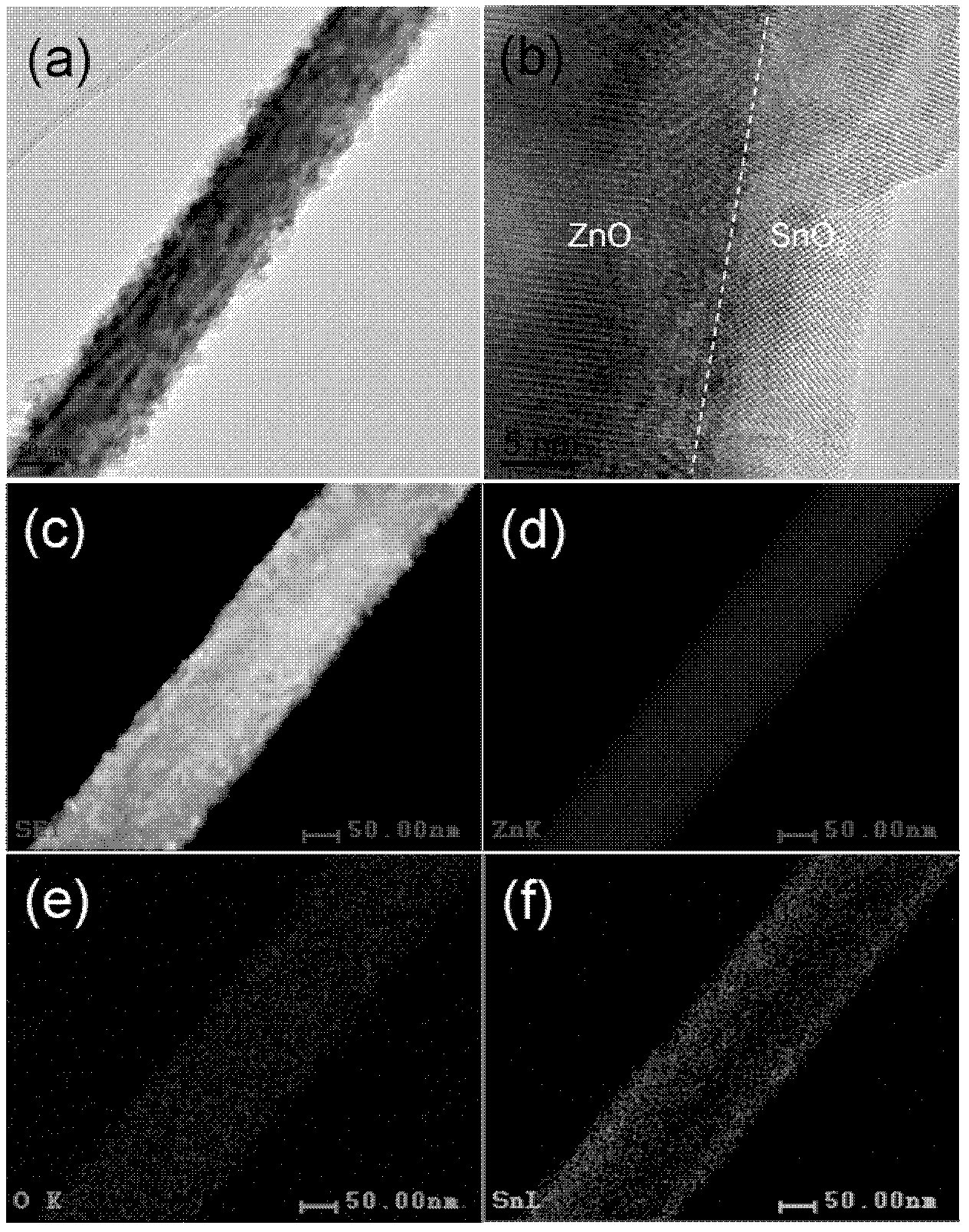

[0027] Take 2g of Zn powder and put it into the ceramic boat, then place the silicon chip substrate on the Zn powder, then place the ceramic boat in the high temperature heating zone of the tube furnace; turn on the mechanical pump, and when the pressure in the furnace drops to 0.1Pa, Introduce 20 sccm of air, control the pressure in the furnace to 80 Pa; raise the high temperature zone of the tube furnace to 550°C, the heating rate is 20°C / min, and the reaction time is 1 hour; after the reaction is completed, wait for the tube furnace to cool down to room temperature After that, take out the silicon wafer, which is loaded with ZnO nanorods;

[0028] Take 3g of SnO powder and put it into a ceramic boat, and then place it in the high-temperature heating zone of the tube furnace; place the silicon chip loaded with ZnO nanorods in the low-temperature deposition zone of the tube furnace; turn on the mechanical pump, and wait until the pressure in the furnace When it is reduced to ...

Embodiment 2

[0030] Get 2g of Zn powder and put it into the ceramic boat, then place the ceramic chip substrate on the Zn powder, then place the ceramic boat in the high temperature heating zone of the tube furnace; turn on the mechanical pump, and when the pressure in the furnace drops to 0.1Pa, Introduce 10 sccm of air, control the pressure in the furnace to 50 Pa; raise the high temperature zone of the tube furnace to 500°C, the heating rate is 15°C / min, and the reaction time is 2 hours; after the reaction is completed, wait for the tube furnace to cool down to room temperature Finally, take out the ceramic sheet, which is loaded with ZnO nanorods;

[0031] Take 3g of SnO powder and put it into a ceramic boat, and then place it in the high-temperature heating zone of the tube furnace; place the ceramic sheet loaded with ZnO nanorods in the low-temperature deposition zone of the tube furnace; turn on the mechanical pump and wait until the pressure in the furnace When it is reduced to 0.1...

Embodiment 3

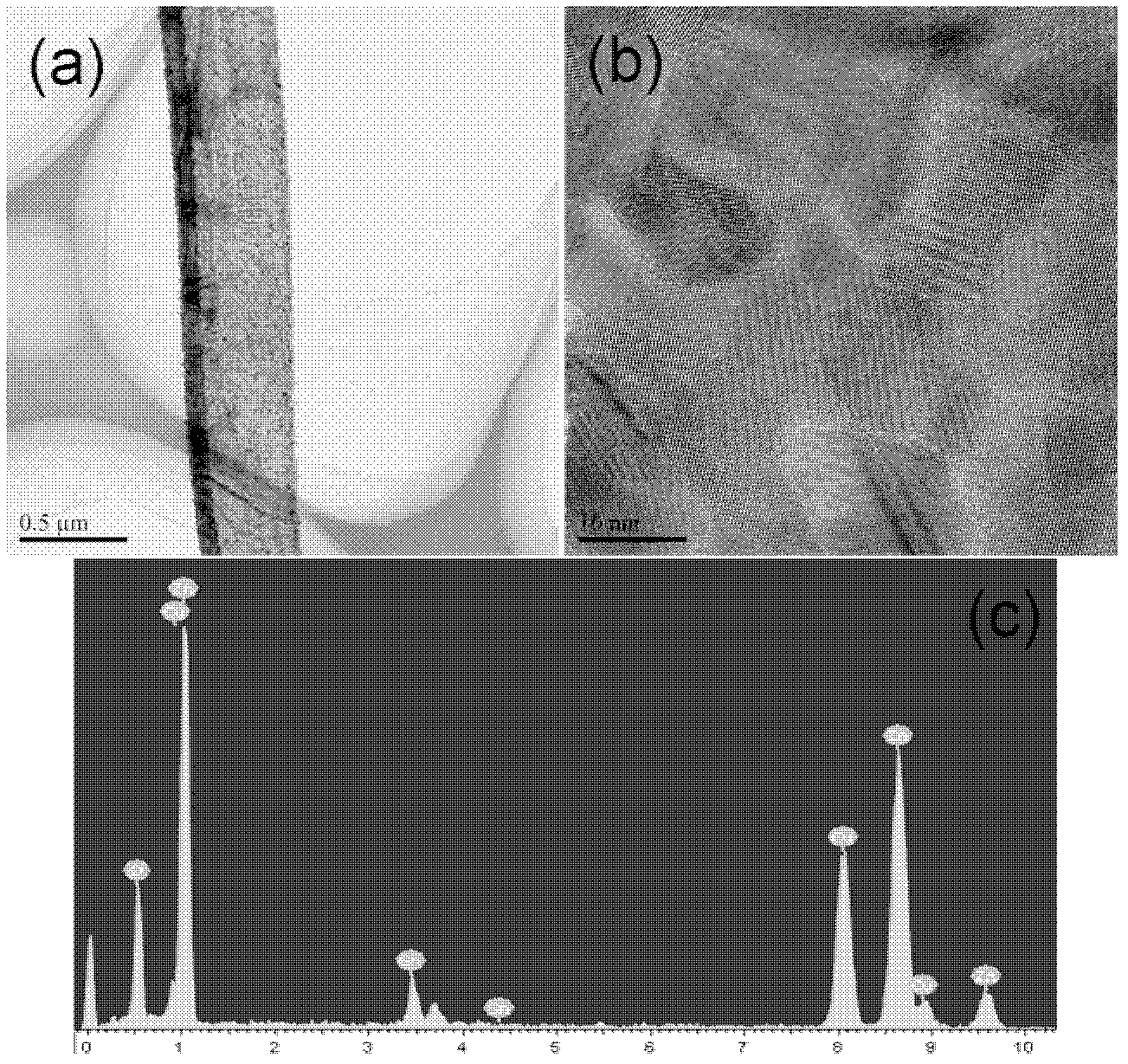

[0033] Take 2g of Zn powder and put it into the ceramic boat, then put the quartz sheet substrate on the Zn powder, then place the ceramic boat in the high temperature heating zone of the tube furnace; turn on the mechanical pump, and when the pressure in the furnace drops to 0.1Pa, Introduce 30 sccm of air, control the pressure in the furnace to 150 Pa; raise the high temperature zone of the tube furnace to 600°C, the heating rate is 25°C / min, and the reaction time is 0.5 hours; after the reaction is completed, wait for the tube furnace to cool down to room temperature Finally, take out the quartz sheet, which is loaded with ZnO nanorods and a small amount of nanobelts;

[0034] Take 3g of SnO powder and put it into a ceramic boat, and then place it in the high-temperature heating zone of the tube furnace; place the quartz sheet loaded with ZnO nanorods in the low-temperature deposition zone of the tube furnace; turn on the mechanical pump and wait until the pressure in the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com