Method for synthesizing NaA zeolite membrane on macroporous carrier

A zeolite molecular sieve membrane, macroporous carrier technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the application field limitation, difficult to obtain high flux and selectivity, chemical stability, thermal stability mechanical problems such as poor stability, to achieve the effect of high repeatability, excellent separation performance, and suitable for large-scale applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1. Carrier tube pretreatment

[0024] Polish the surface of the carrier tube with 600# and 800# waterproof sandpaper in turn until the surface of the carrier is smooth, then use acid and alkali ultrasonic vibration to remove the residue in the carrier hole, wash with deionized water until neutral, and then dry naturally. Finally, dry it at a temperature of 150° C. for later use.

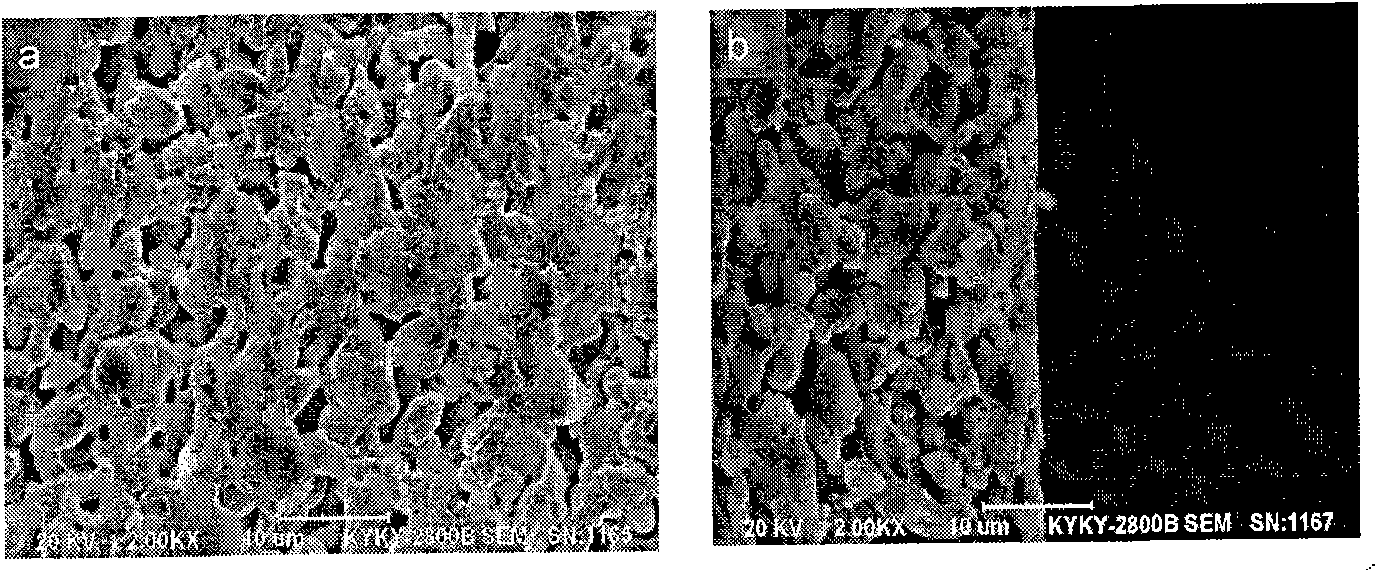

[0025] Step 2. Preparation of carrier seed layer

[0026] (1) Apply large seed crystals on the treated carrier tube by hot dipping-wiping coating method: heat up the self-made NaA molecular sieve with a grain size of 1-3 μm to 550 °C at a rate of 1K / min, and keep 4h, to remove the organic template in the molecular sieve, and then configure it into a 10% seed crystal aqueous solution, quickly immerse the carrier tube that has been baked at 180°C for 4h into the above seed crystal solution, and the immersion time is 20s. Afterwards, the carrier tube coated with the seed crystals is dried ...

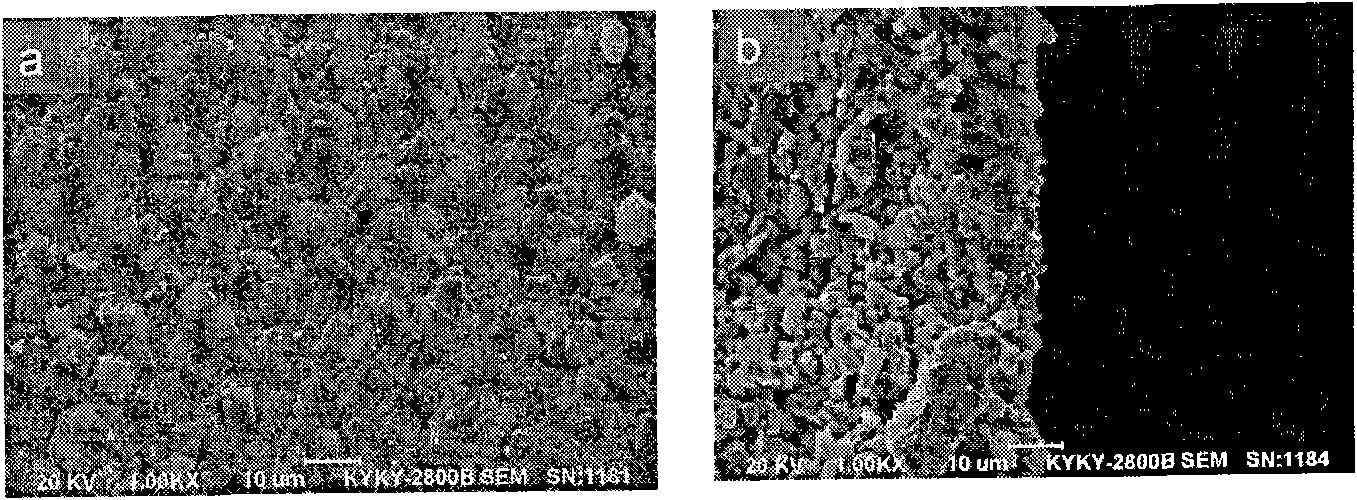

Embodiment 2

[0032] Step 1. Carrier tube pretreatment

[0033] Same as step 1 in Example 1.

[0034] Step 2. Preparation of carrier seed layer

[0035] This time, only the hot dipping-wiping method was used to coat the large seeds on the surface of the carrier, and no small seeds were coated. Step is the same as the process (1) in step 2 in embodiment 1.

[0036] Preparation of step 3.NaA zeolite molecular sieve membrane

[0037] The separation selectivity of the NaA zeolite membrane synthesized by one-step crystallization needs to be improved because only a large seed crystal is coated. In order to further improve the separation performance of the NaA zeolite membrane, a two-step crystallization synthesis is adopted. The first step synthesis process is completely the same as Step 3 in Example 1. The second step of synthesis then changes the conditions and formula, and the specific implementation process is as follows: in a 200ml beaker, 6.80g NaAlO 2 and 2.072g NaOH were fully dissol...

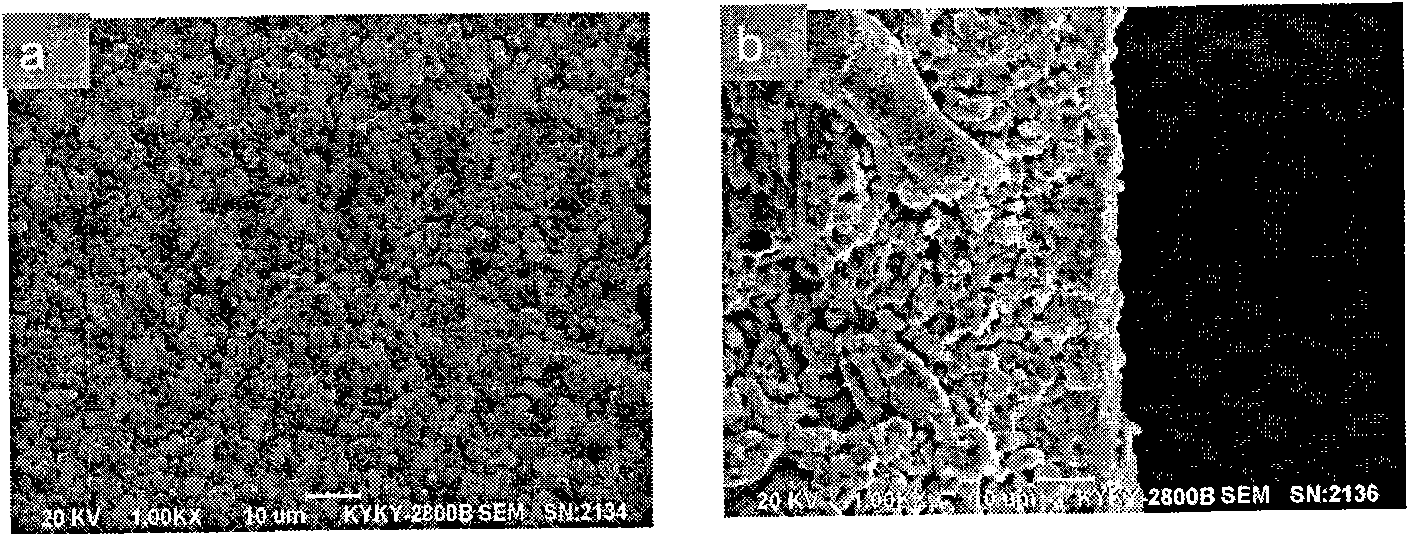

Embodiment 3

[0040] Carry out the pervaporation performance research of ethanol / water system respectively to the film tube synthesized in embodiment 1 and embodiment 2, its flow process is as follows image 3 As shown, for an ethanol / water system with a mass fraction of ethanol of 90%, the operating temperature is 70°C, and the vacuum on the permeation side is 200-400Pa, the separation coefficient and permeation flux of the NaA molecular sieve membrane synthesized are 5000-400 Pa, respectively. 10000 and 1.5~2.0kg / m 2 h. It shows good separation performance and has important industrial application value and practical significance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com