Punched workpiece defect detection method based on image processing

A technology for stamping workpieces and defect detection. It is applied in image data processing, image enhancement, image analysis, etc., and can solve the problems of low detection efficiency, high cost, and poor repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

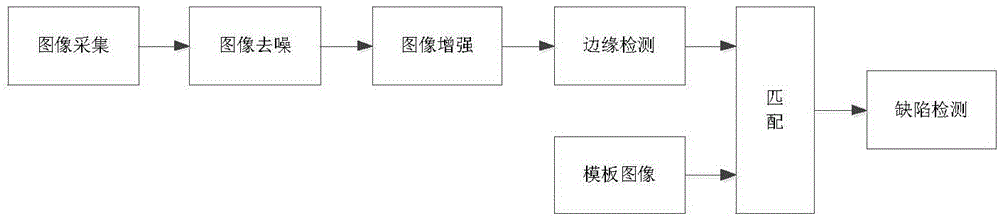

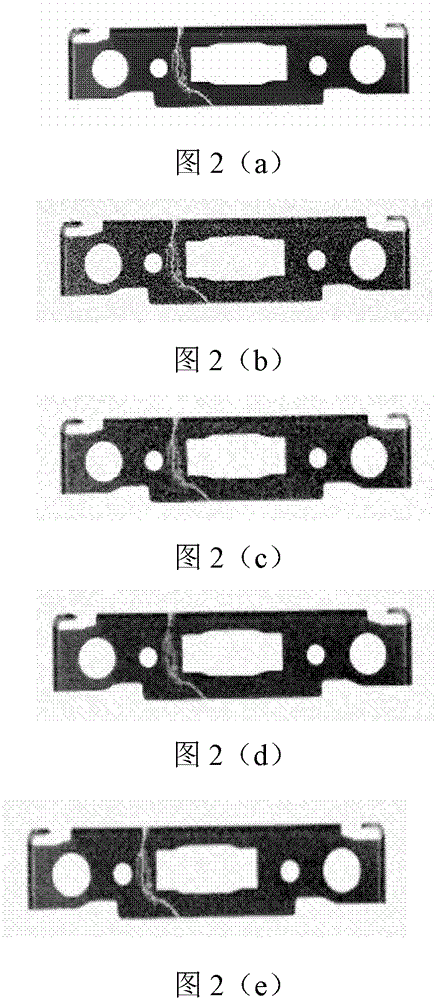

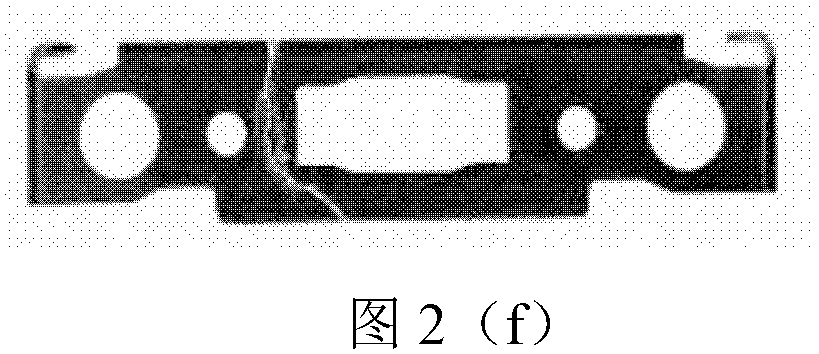

[0082] The process flow of a method for detecting stamping workpiece defects based on image processing in the present invention is as follows figure 1 As shown, the specific detection steps are:

[0083] Step 1, use the light source, high-definition CCD camera, and image acquisition card to obtain the image of the stamping workpiece, and use the adaptive voting fast median filter method to perform image denoising processing:

[0084] Step 1.1: Divide the acquired workpiece image into N×N filtering sliding windows, where N≥3, and N is an odd number;

[0085] Step 1.2: Scan the pixels in the filtering sliding window obtained in step 1.1 one by one, and set the pixel value of the center point x ij The pixel value θ of its neighboring pixels ab for comparison, when x ij = θ ab , vote for the gray value of the pixel; and judge x ij Whether i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com