Graph cutting and sorting processing method applied to laser cutting numerical control machining

A processing method, laser cutting technology, applied in the direction of general control system, program control, computer control, etc., can solve the problems of low efficiency, frequent, rigid knife lifting, etc., to improve cutting efficiency, improve processing effect, and avoid redundant operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

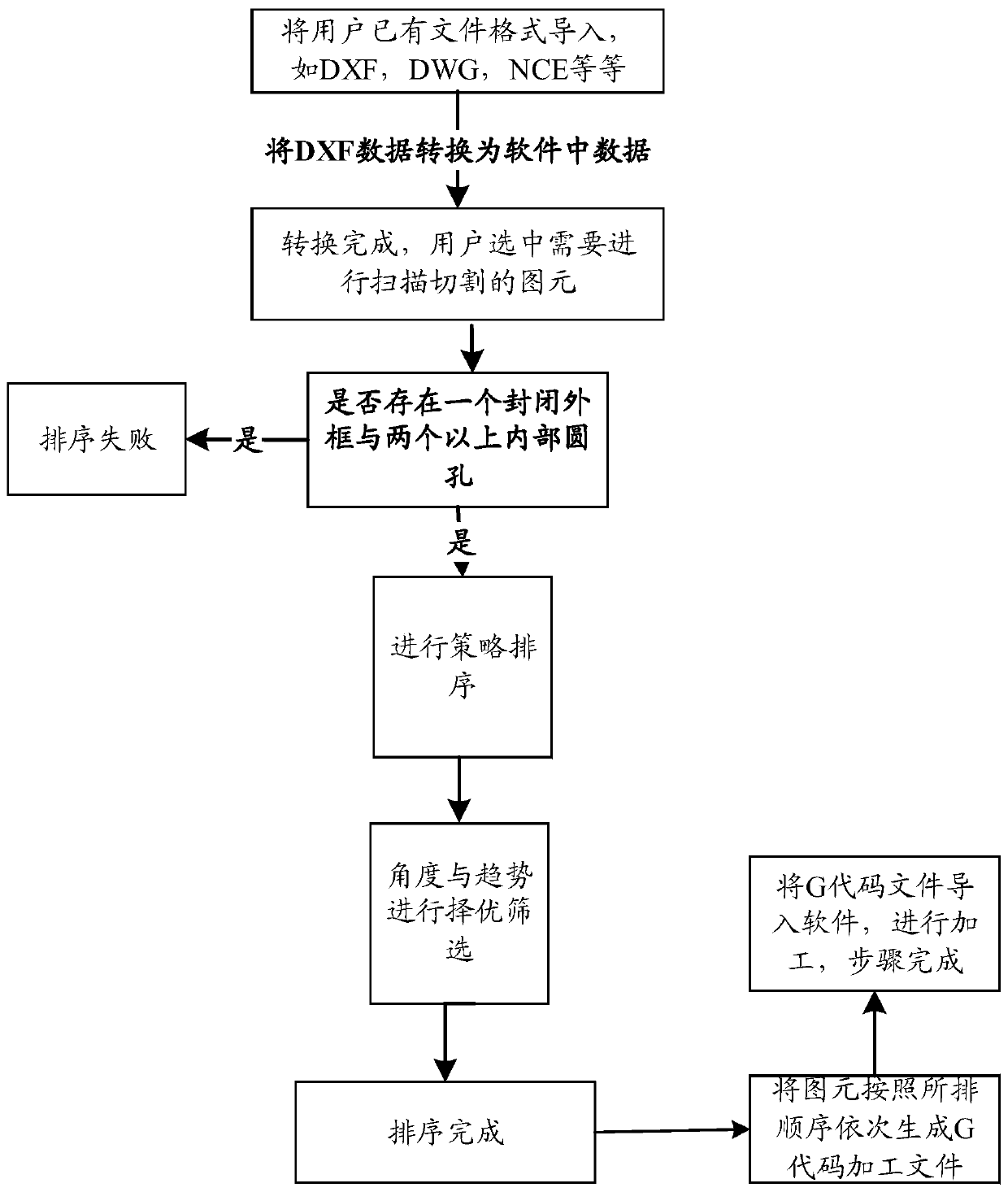

[0025] The graphics cutting and sorting processing method applied to laser cutting numerical control processing of the present invention includes the following steps:

[0026] (1) Import the CAD file into the laser numerical control system, convert it into graphic metadata according to the file format, and select the graphic metadata to be processed;

[0027] (2) Judging whether there is at least one closed frame graphic element in the selected graphic element data, and there are at least two circular hole graphic elements inside, if yes, then continue to step (3); otherwise, the sorting fails and exits the step;

[0028] (3) Carry out strategic sorting on the processing angle and processing path trend direction of the primitive data;

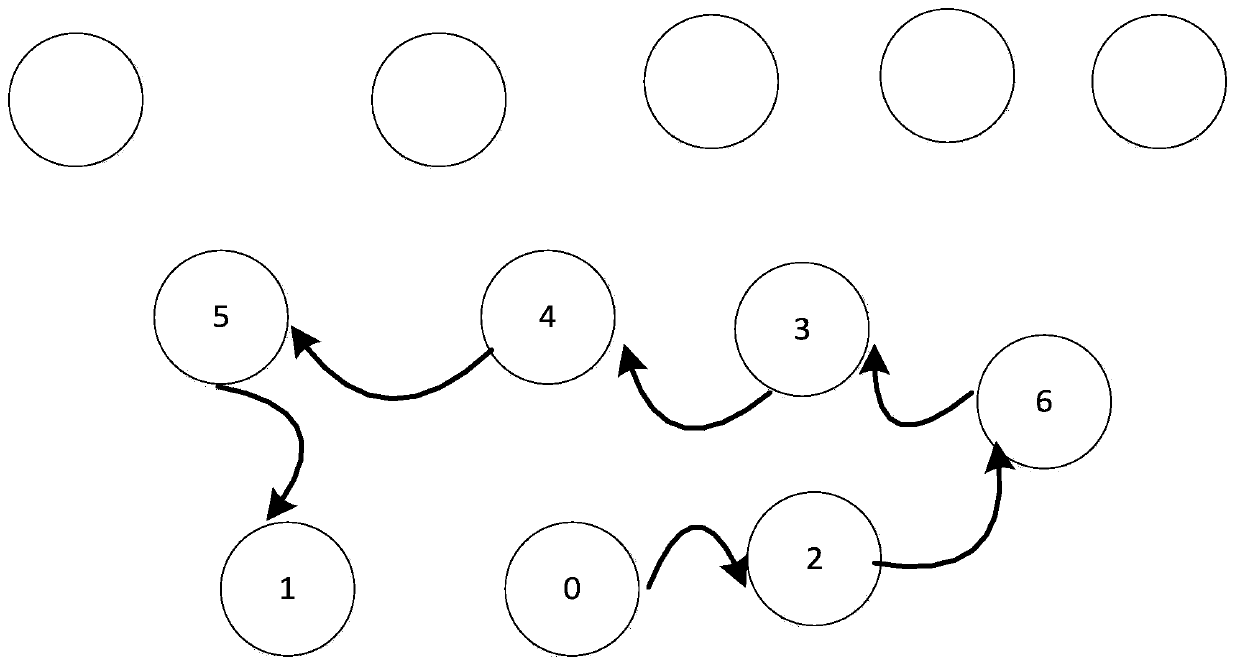

[0029] (3.1) according to the circle center of the circle hole of prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com