Automatic material cutting and forming method and system thereof

An automatic cutting and forming method technology, which is applied in the field of CNC machine tools, can solve the problems of unfavorable resource saving, high labor intensity of workers, and low cutting efficiency, and achieve the effects of improving typesetting accuracy, realizing automatic cutting, and increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

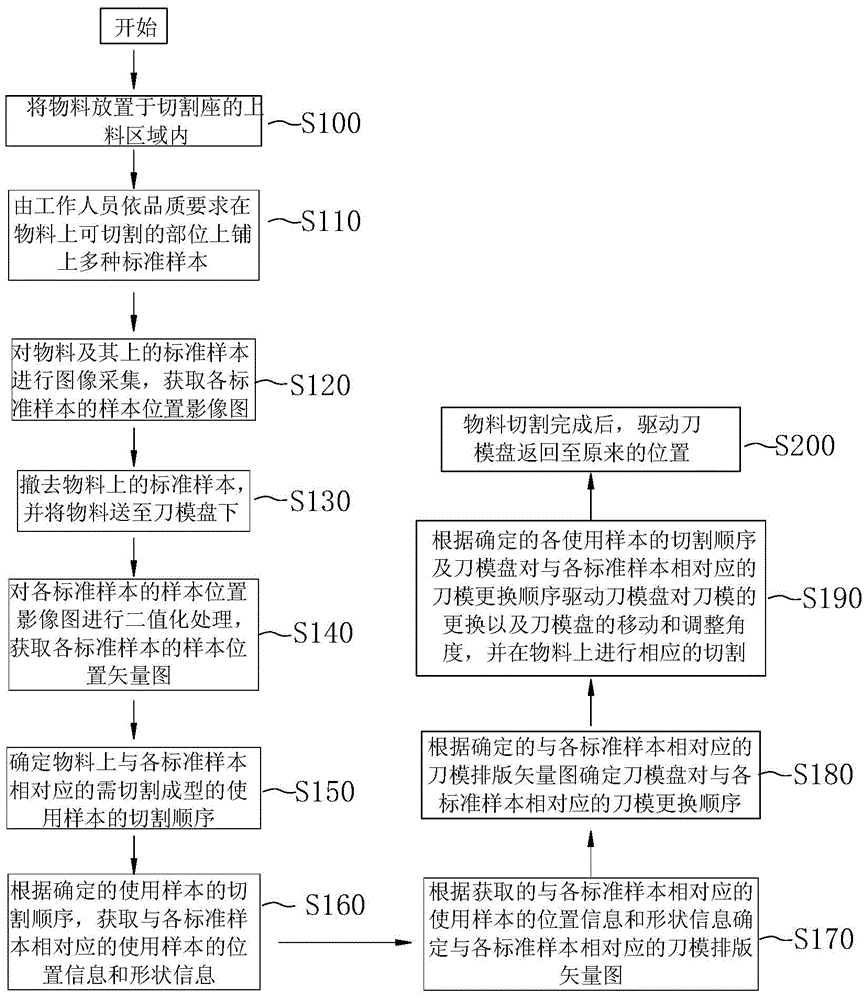

[0049] Please refer to figure 1 , figure 1It is a flow chart of a method for automatic cutting and forming of materials provided in the first embodiment, which includes:

[0050] S100, laying the material flat on the feeding area of the cutting seat;

[0051] Specifically, the material is placed in the feeding area of the cutting seat, and placed flat on the loading plate that can move on the cutting seat, so that the material can be conveniently transported to the die plate.

[0052] In this embodiment, the carrier board is one piece.

[0053] S110. Lay a variety of standard samples on the parts that can be cut by the staff according to the quality requirements;

[0054] Specifically include: the inspection of the material quality by the staff determines the typesetting of the standard sample on the material;

[0055] If the staff inspects the material without damage, the staff will lay multiple standard samples on the entire material, and manually optimize the typese...

Embodiment 2

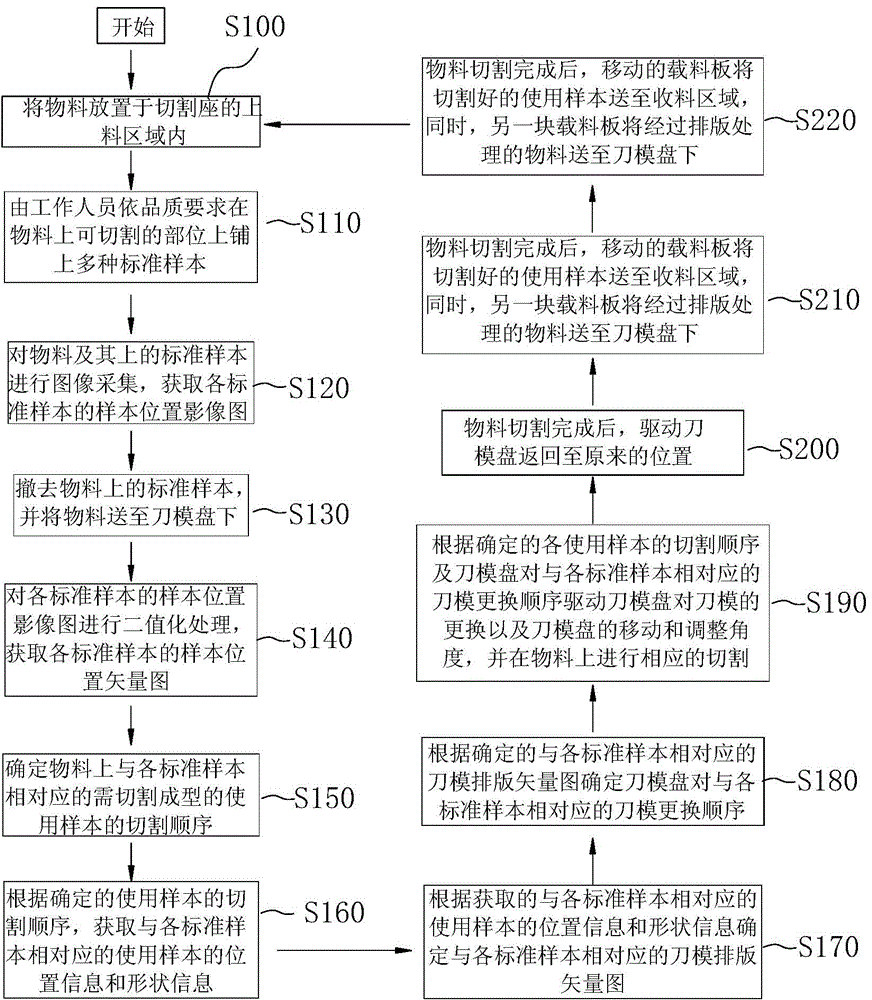

[0074] Please refer to figure 2 , figure 2 It is a flow chart of a method for automatically cutting and forming materials provided in the second embodiment. It differs from the first embodiment in that: there are at least two carrier plates, and at least two carrier plates move circularly on the cutting seat. And after the step S200, it also includes:

[0075] S210. After the cutting of the material is completed, the moving loading plate sends the cut samples to the receiving area, and at the same time, another loading plate transports the typesetting-processed materials to the die tray.

[0076] This step can realize the continuity of material cutting, so that after the material on one loading plate is cut, the other loading plate can carry the material to the die plate, shortening the time between two adjacent material cuttings. The time for exchange under the mold greatly improves the processing efficiency of the entire automatic cutting system.

[0077] S220. The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com