Method, device, storage medium and computer device for planning laser cutting path

A path planning and laser cutting technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of cutting time, irrationality, and low cutting efficiency of path planning scheme cutting path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Before explaining the technical solution of this application, some relevant content in the laser cutting technology will be explained first.

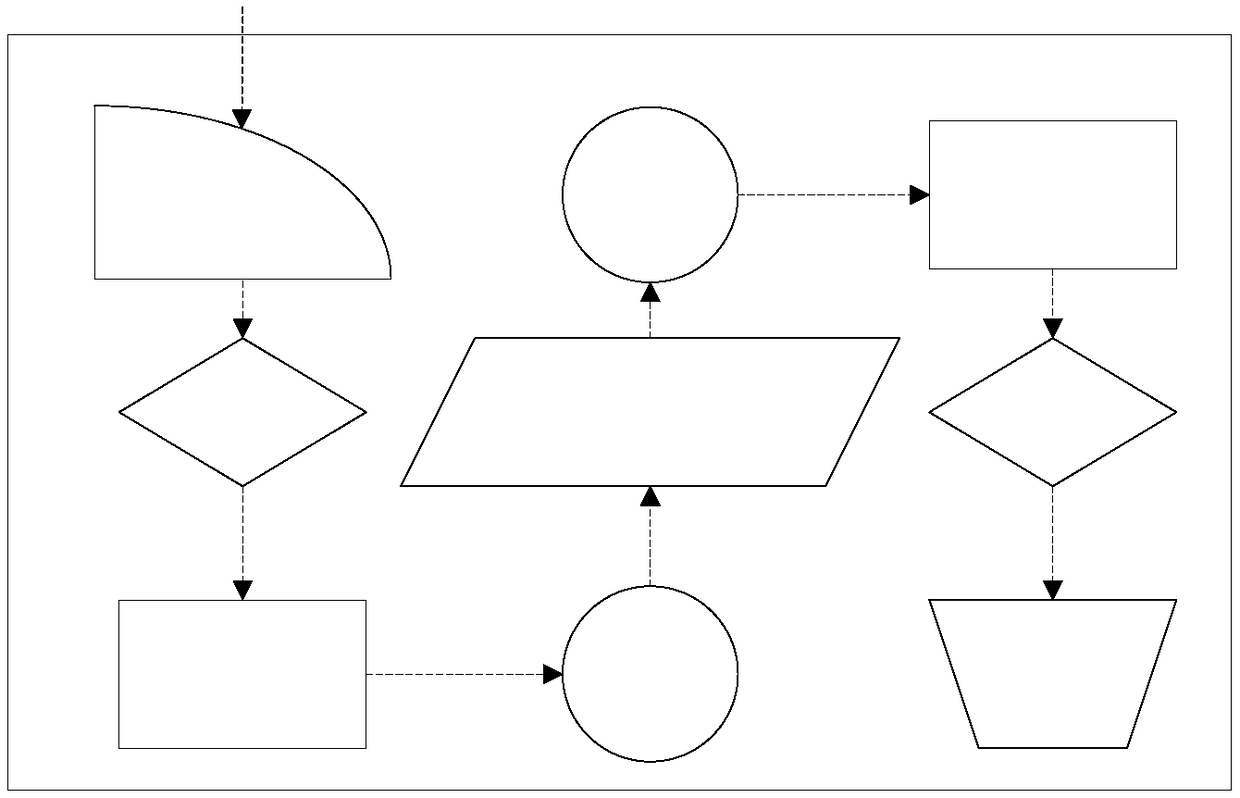

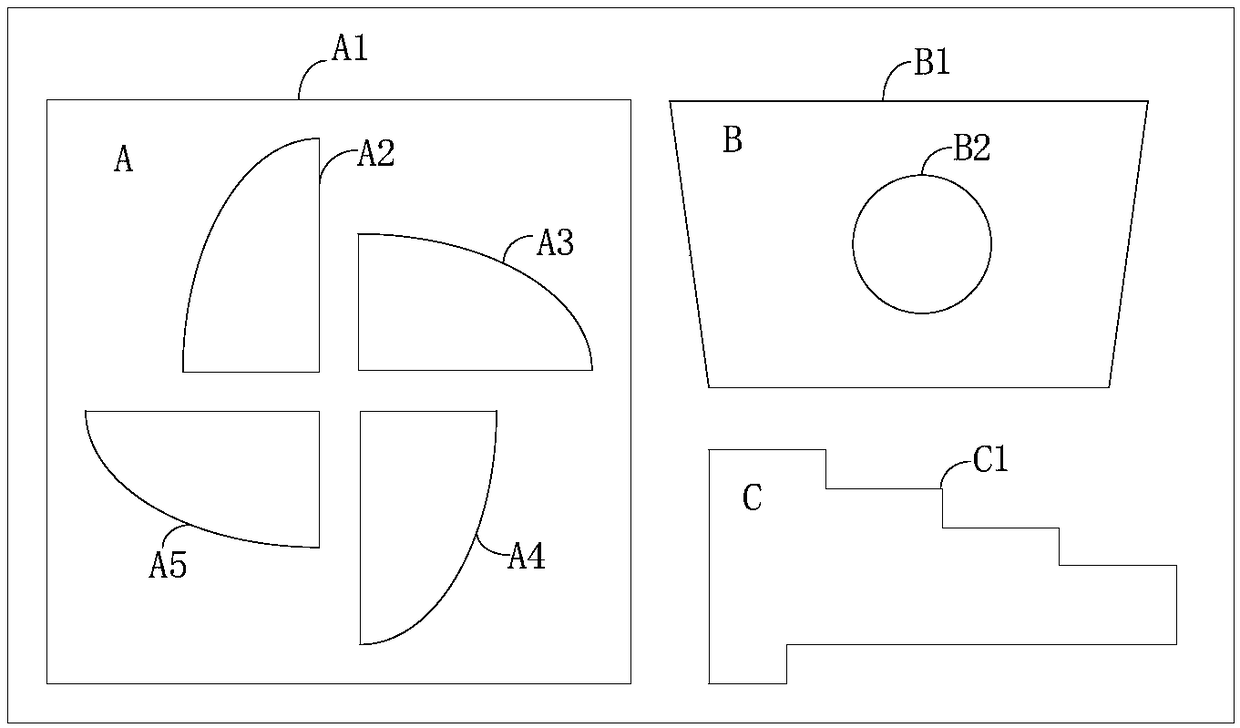

[0033] The most basic geometric unit of laser cutting graphics is the contour, which is a closed figure composed of straight lines and arcs. For any simple or complex contour, we can define the connection point between the straight line and the straight line, the connecting point between the straight line and the arc, and the connecting point between the arc and the arc as the vertices of the contour, and the straight line or arc that will constitute the contour Defined as an edge, for a circular profile, its vertices can be at any position. refer to figure 1 , typical contours include circles, polygons, special-shaped contours composed of straight lines and arcs, etc.

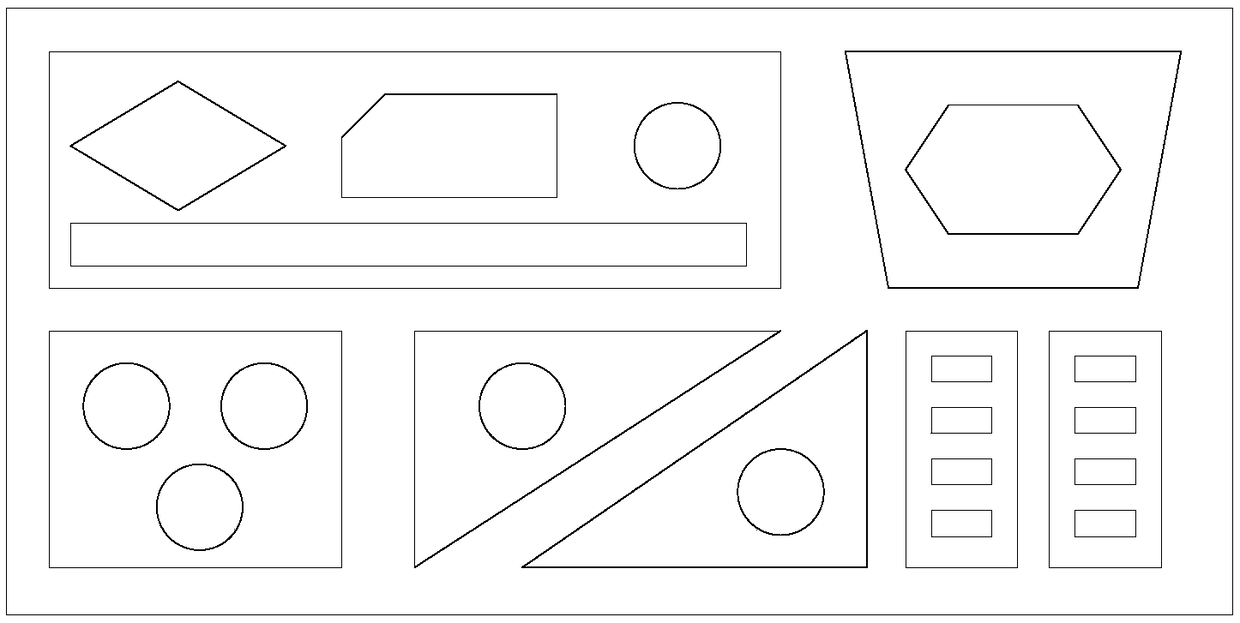

[0034] Parts are composed of contours and are the most direct output of laser cutting. Such as figure 2 As shown, a complete part to be processed contains a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com