Cutting path optimization method and device and computer readable storage medium

An optimization method and cutting path technology, applied in the direction of electrical program control, manufacturing tools, laser welding equipment, etc., can solve the problems of low effectiveness and optimization efficiency, to ensure path optimization efficiency, improve effectiveness, and short air travel distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

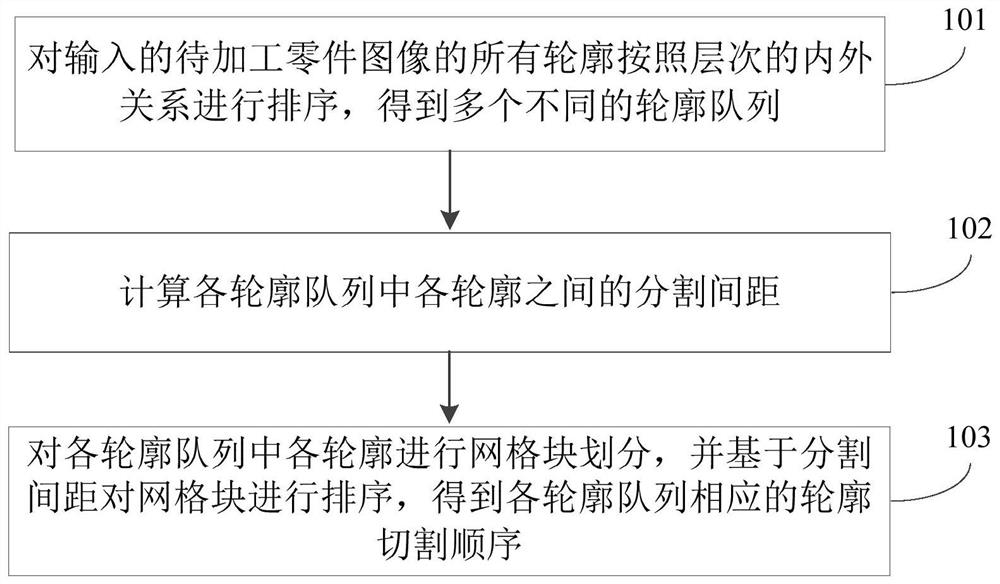

[0028] In order to solve the technical problem that the result effectiveness and optimization efficiency of the laser cutting path optimization method provided in the related art are low, this embodiment proposes a cutting path optimization method, which is applied to the laser cutting system, mainly for laser cutting parts. The contour is optimized for the path, and the path optimization process can be realized through CAM software programming. Such as figure 1 Shown is a schematic flow chart of the cutting path optimization method provided in this embodiment. The cutting path optimization method proposed in this embodiment includes the following steps:

[0029] Step 101. Sorting all the contours of the input image of the part to be processed according to the internal and external relations of the hierarchy to obtain multiple different contour queues.

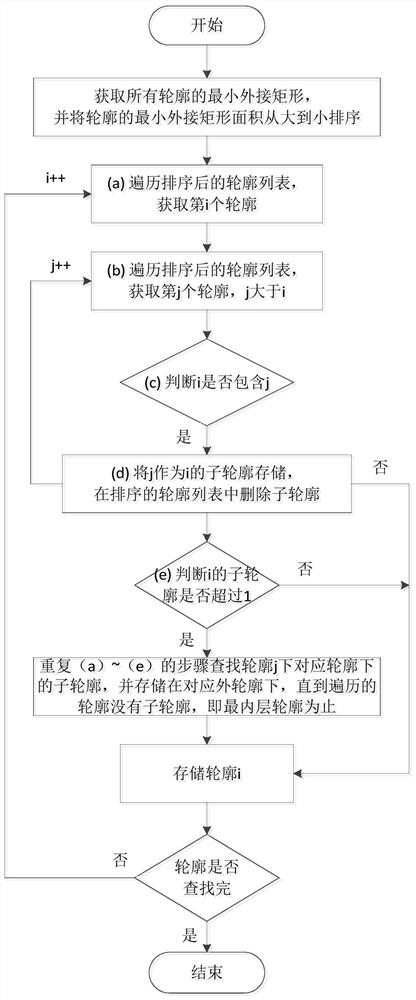

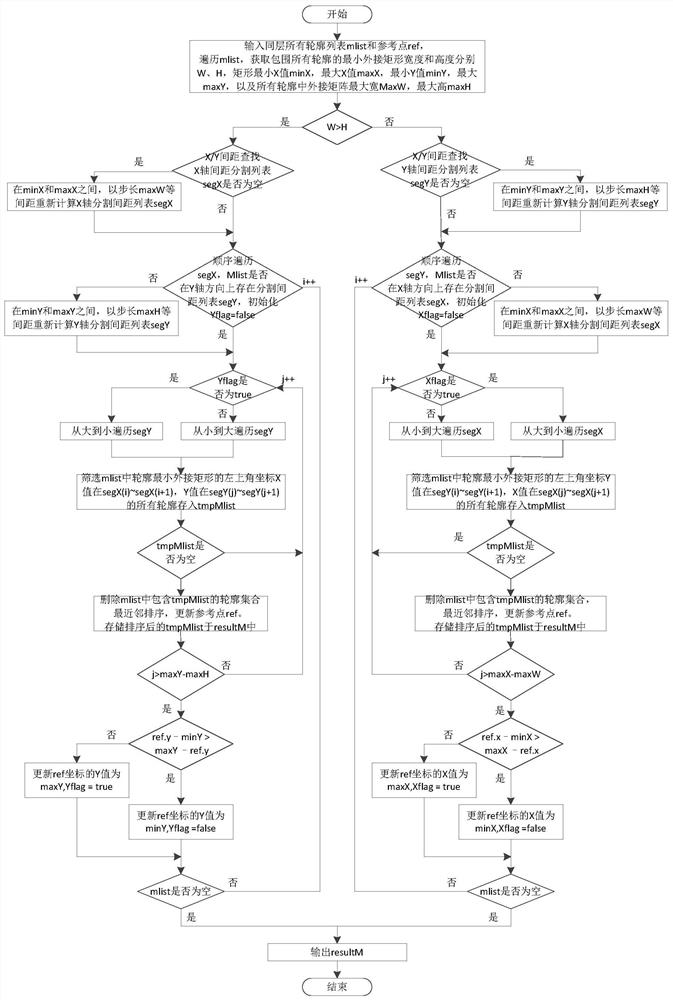

[0030] Specifically, the outline queue in this embodiment includes the outer outline and the inner sub-outline mounted unde...

no. 2 example

[0059] In order to solve the technical problem that the result effectiveness and optimization efficiency of the laser cutting path optimization method provided in the related art are low, this embodiment shows a cutting path optimization device, which is applied to the laser cutting system. For details, please refer to Figure 5 , the cutting path optimization device of this embodiment includes:

[0060] The sorting module 501 is used to sort all the contours of the input image of the part to be processed according to the internal and external relations of the hierarchy to obtain a plurality of different contour queues; wherein, the contour queues include outer contours and those mounted under the outer contours The inner sub-profile of ;

[0061] Calculation module 502, for calculating the segmentation distance between each contour in each contour queue;

[0062] The optimization module 503 is configured to divide each contour into grid blocks in each contour queue, and sort...

no. 3 example

[0072] This embodiment provides an electronic device, see Image 6 As shown, it includes a processor 601, a memory 602, and a communication bus 603, wherein: the communication bus 603 is used to realize connection and communication between the processor 601 and the memory 602; the processor 601 is used to execute one or more programs stored in the memory 602 A computer program to implement at least one step in the cutting path optimization method in the first embodiment above.

[0073] The present embodiment also provides a computer-readable storage medium, which includes information implemented in any method or technology for storing information, such as computer-readable instructions, data structures, computer program modules, or other data. volatile or nonvolatile, removable or non-removable media. Computer-readable storage media include but are not limited to RAM (Random Access Memory, random access memory), ROM (Read-Only Memory, read-only memory), EEPROM (Electrically E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com