Engine hood lightweight design method based on radial basis function neural network approximation model

A technology based on neural network and lightweight design, which is applied in the field of lightweight design of engine hood based on RBF approximate model of radial basis neural network, can solve the problems of high cost, long calculation time, limited effect, etc., and achieves lightweight design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

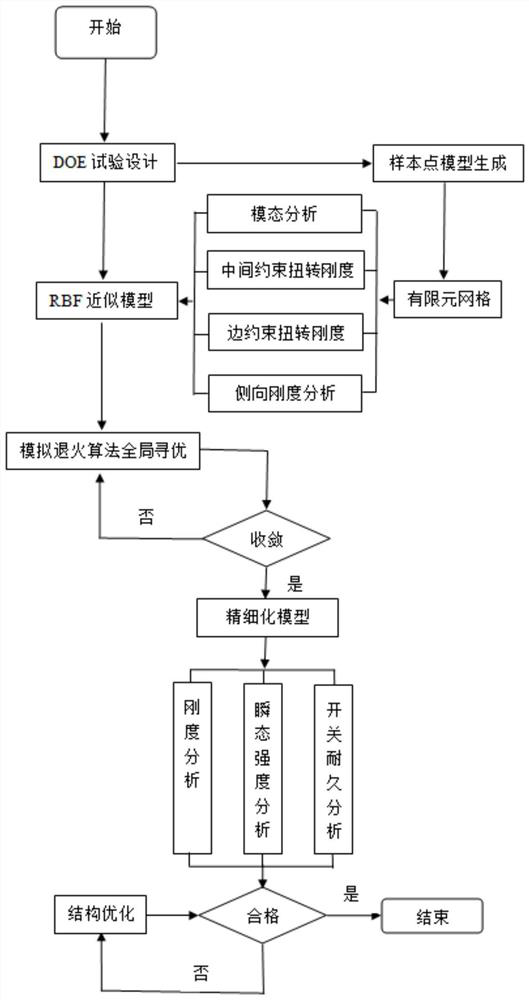

[0065] refer to figure 1 , the engine hood lightweight design method based on radial basis neural network RBF approximation model of the present invention, comprises the steps:

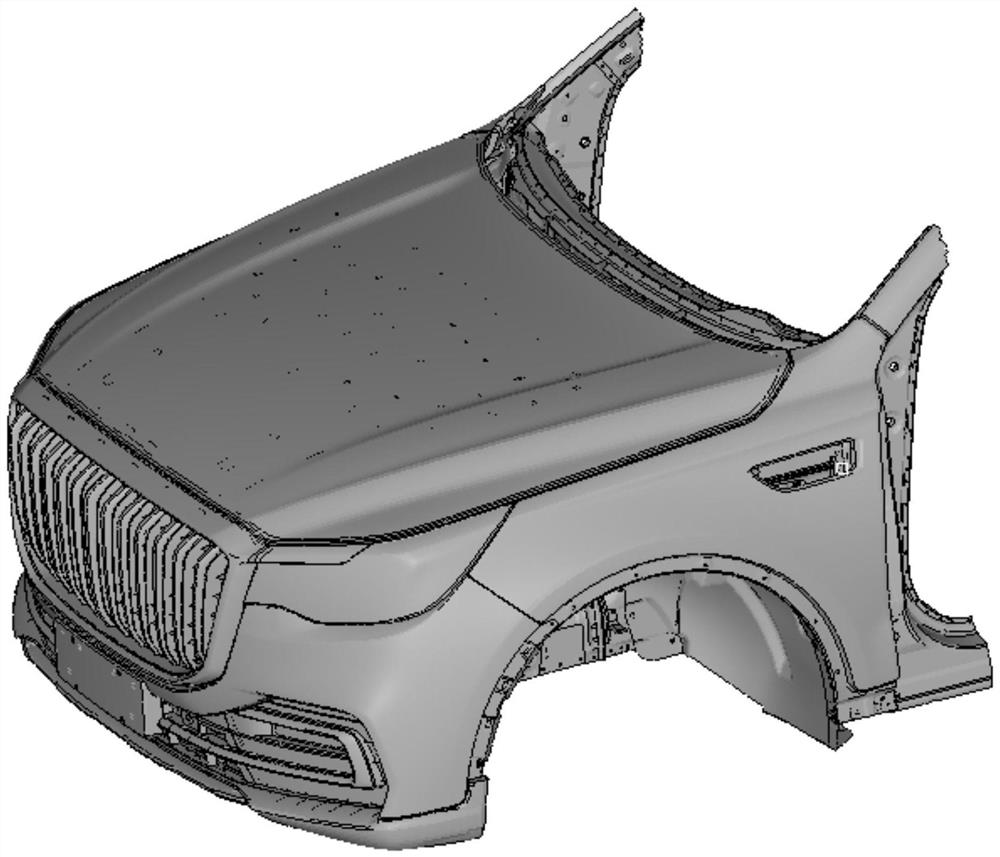

[0066] S1: Establish the finite element model of the sheet metal parts of the hood assembly, and complete the calculation of the finite element model boundary conditions and load settings for the four analysis conditions of the hood modal, lateral stiffness, intermediate constraint torsional stiffness, and side constraint torsional stiffness.

[0067] S2: Select the material thickness of each sheet metal part of the engine hood as a design variable, and set the variable range as a discrete variable according to the actual variable range of material thickness of each sheet metal part.

[0068] S3: Use the orthogonal matrix method to select the variable test matrix, output the finite element model corresponding to each variable under the test matrix, and analyze and calculate the modal, lateral stiffnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com