Multi-brand scheduling and switching mixed optimizing method in polypropylene production process

A brand switching and production process technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problem of difficulty in ensuring the coordination and optimization effect of scheduling sequences and switching trajectories and device operation stability, difficulty in ensuring convergence, and low solution efficiency, etc. problem, to achieve the effect of reducing the total consumption of transition materials, reducing the optimization scale, and reducing the switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings.

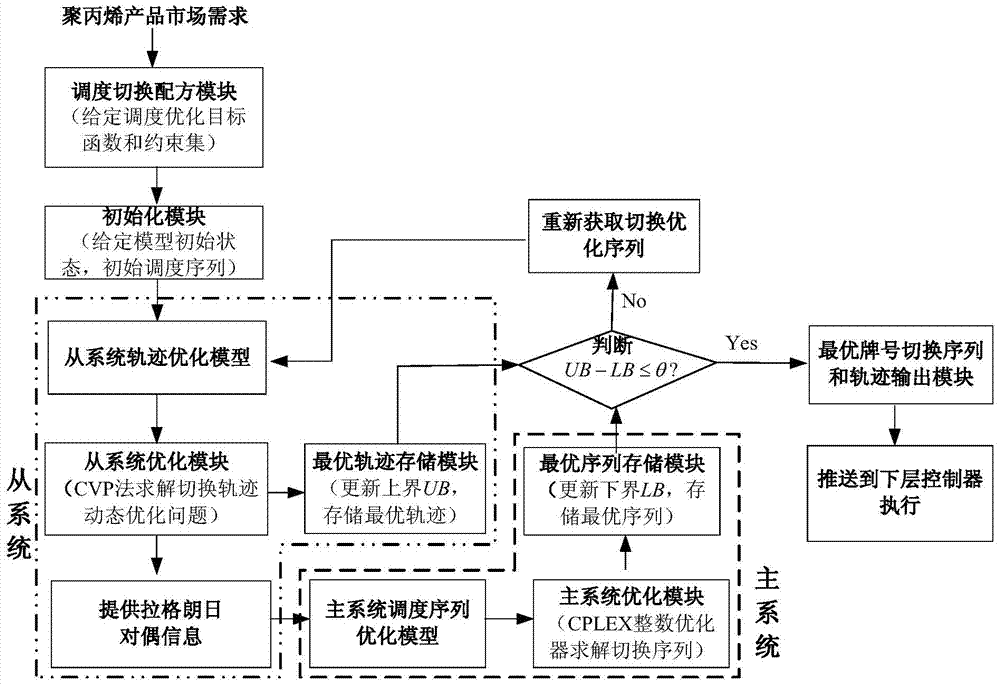

[0051] refer to figure 1 , figure 2 A mixing optimization method for multi-brand scheduling switching in the production process of polypropylene, the specific implementation method is as follows:

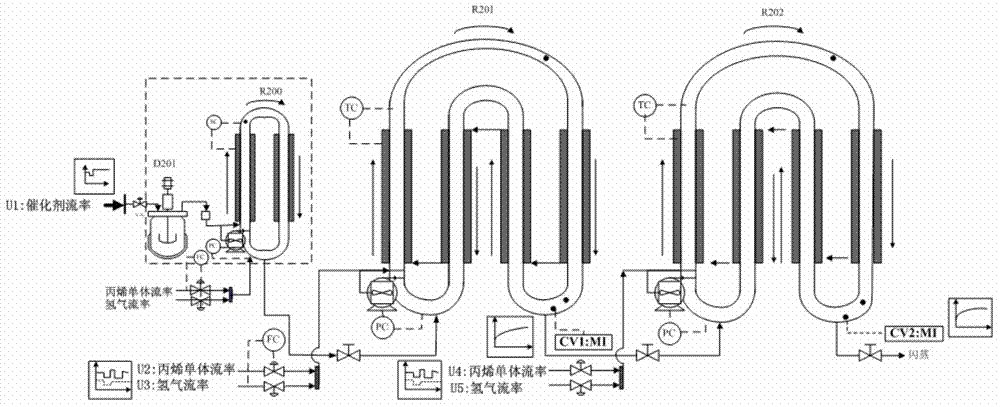

[0052] (1) Determine the product brand scheduling switching formula for polypropylene production. The 2# double-loop process liquid phase propylene bulk polymerization device of a branch of Sinopec (such as figure 1 Shown) as the target, the factory concentrates on producing four polypropylene grades (film grade S38F, wire drawing grade T30S, general grade Z30G, fiber grade F39S, defined as grades A, B, C, D) in a certain period of time according to market demand. (See Table 1).

[0053] Table 1 Four kinds of polypropylene grade products scheduled and produced by a branch of Sinopec in a certain period

[0054]

[0055]

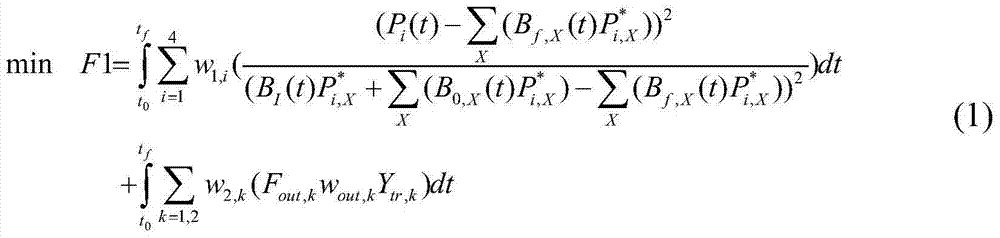

[0056] Based on the actual production con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com