Saw cutting method of square pipe saw cutting machine

A sawing machine and sawing technology, applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve problems such as increased production costs, long tails, and reduced profits, so as to improve utilization and reduce production costs , The effect of improving sawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

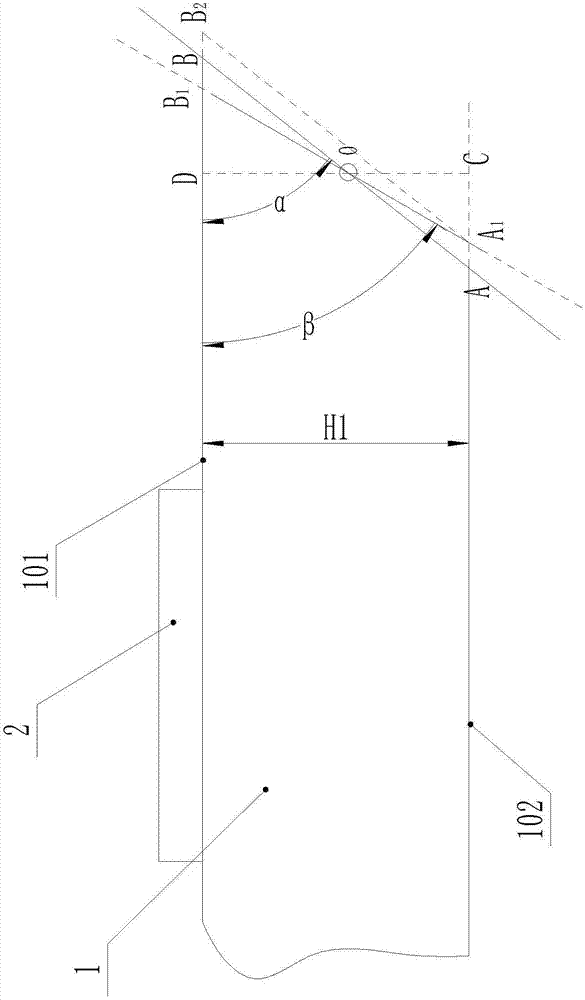

[0037] Such as figure 1 As shown, this embodiment one is cut according to the above-mentioned whole cutting method. First, the cross section of the square tube can be square or rectangular. There is no need to turn the material before cutting. Of course, in general industries, it is also necessary to cut on a special surface, and the material turning operation is also required. If the cross-section of the square tube is rectangular, it is necessary to turn over the material of the rectangular square tube so that the specific side of the square tube faces up so that it can be cut in the specified placement state. And this turning over process realizes when the loading of square tube, be in the patent No.: ZL201510134362.4 name discloses the feeding and turning over of rectangular tube in the patent of a kind of rectangular tube automatic feeding device, here will not repeat.

[0038] In this embodiment, the production piece to be sawed is β>α. After setting the cut production...

Embodiment 2

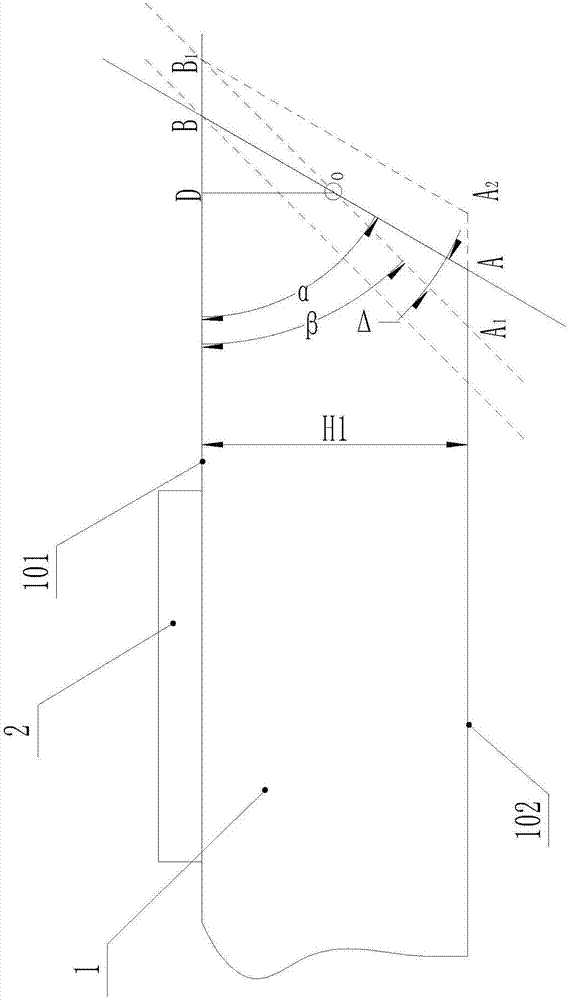

[0045] This embodiment is basically similar to the sawing method of Embodiment 1, except that when the end angle β of the first end of the target production part selected from the production part task list is smaller than α, the angle of the pipe end of the square pipe 1 is retained. The apex of the retained angle α is used as a reference point to cut off the Δ angle, Δ=|β-α|, and then the length to be transported by retaining the square tube 1 when the first end is to be cut is calculated through the trigonometric function relationship, and the sawing machine is according to The calculation result is pinched and retained. The square tube 1 is transported to the specified length and cuts the first end angle of the target production piece, and then the saw blade 17 is rotated to the same angle as the other end angle of the target production piece, and then through the trigonometric function The relationship calculates the length to be conveyed when cutting the other end, and the...

Embodiment 3

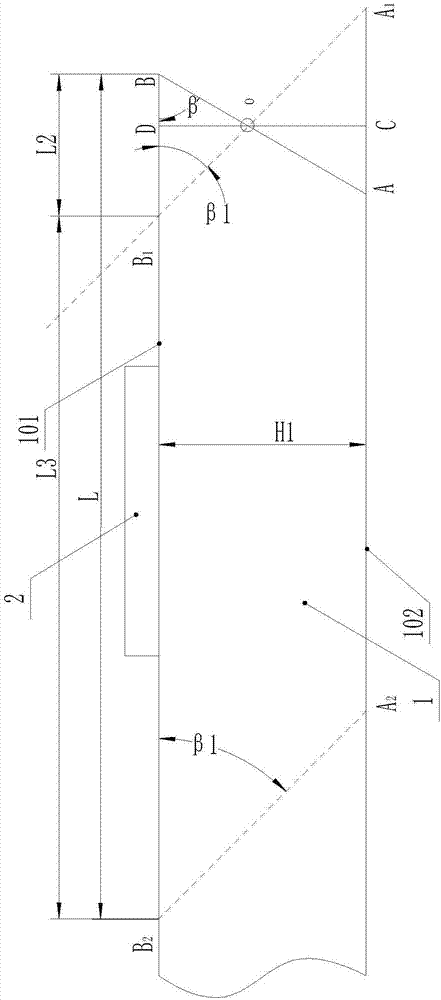

[0049] Such as Figure 4 As shown, this embodiment is basically similar to the sawing method of Embodiment 1 and Embodiment 2, the first end of the production piece can be sawed according to the sawing method in Embodiment 1 and Embodiment 2, but the production piece The angle line of the second end is different from the angle line in the first embodiment, that is to say, the angle line A in the first embodiment 2 B 2 Angle with the downstream pointing plane of datum plane 101 image 3 β shown in 1 is an acute angle, the angle line A in Example 3 2 B 2 The included angle with the downstream pointing surface of the datum plane 101 is an obtuse angle such as Figure 4 180°-β shown 1 , the initial state of the saw blade 17 in this embodiment is on the AB line, and then the saw blade 17 rotates to A 1 B 1 On the straight line, the line segment A 1 B 1 End angle β with second end 1 same as Figure 4 Among them, as above, it can be seen that since the length of the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com