Shield tunneling machine cutterhead suitable for expansible old clay

A shield machine and expansive technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problem that the rationality of the distribution position and the firmness of the installation cannot meet the requirements, the abnormal wear of the cutter head and the cutter, and the impact on the shield machine. Improve the construction efficiency of shield tunneling, optimize the cutting trajectory and cutting sequence, and achieve the effect of novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

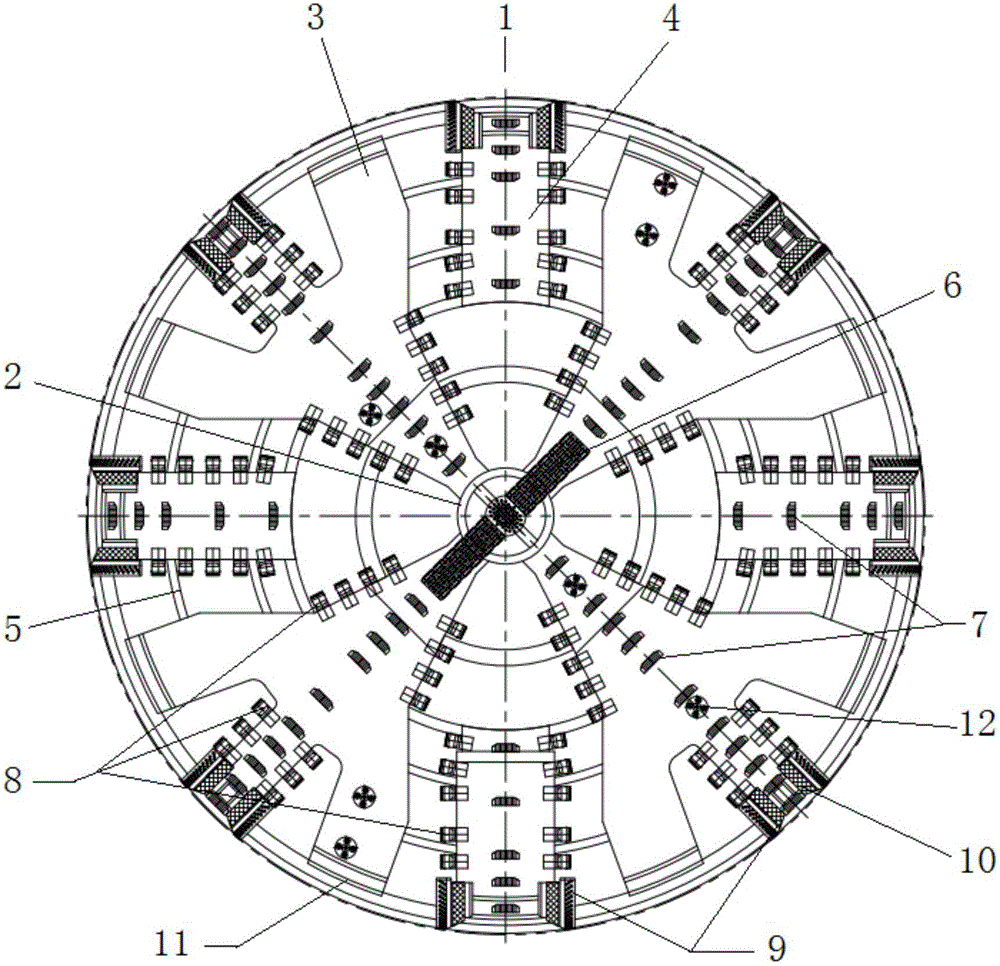

[0021] See attached picture:

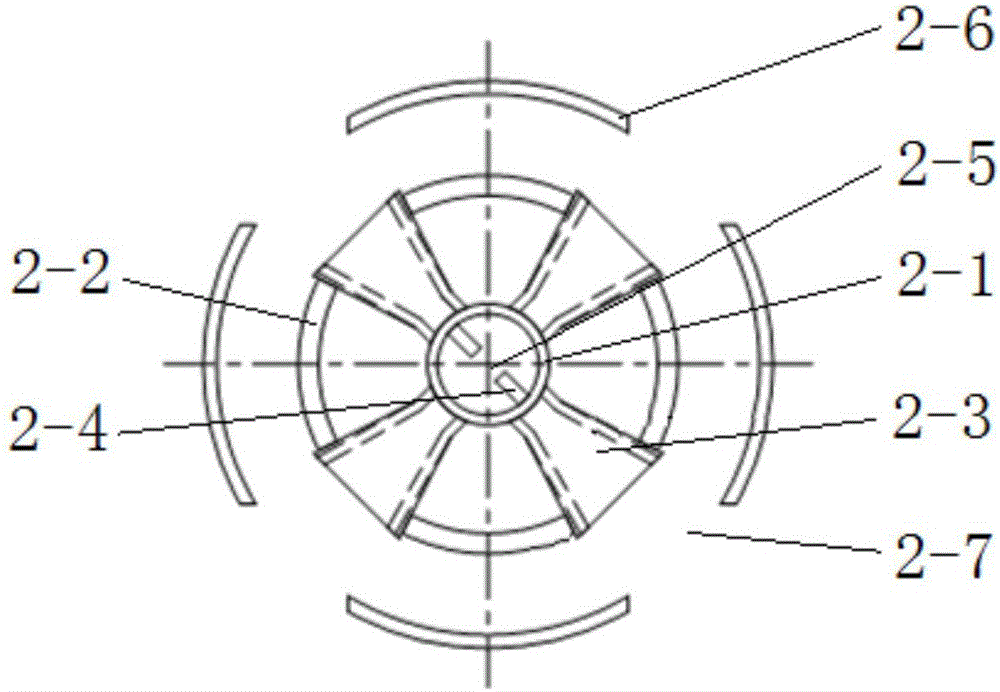

[0022] The shield machine cutter head suitable for expansive old clay includes a disk body 1, a composite panel 2 is arranged in the center of the disk body 1, and four main ribs 3 and four spokes 4 are arranged on the periphery of the composite panel 2. The four main ribs 3 are connected with the combination panel 2 to form a cross shape, and the disc body between two adjacent main ribs 3 is provided with spokes 4, and the ends of the spokes 4 are fixed with the combination panel 2, and the spokes 4 and the combination panel 2 are fixed. The main ribs 3 are fixed by steel grids 5 arranged at annular intervals,

[0023] The center of the combination panel 2 is equipped with a reinforced central fishtail scraper 6 arranged along the diameter direction, and the number is 12. The central fishtail scraper is arranged in a row, and the reinforced central fishtail scraper 6 and two of them on a straight line The centerlines of the main floors coincide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com