Automatic cutting machine and cutting method for nylon heat insulation strip production line

A nylon thermal insulation strip and cutting machine technology, applied in metal processing and other directions, can solve the problems of high danger of nylon thermal insulation strips, low cutting quality and efficiency, splashing of nylon thermal insulation strips, etc. The effect of small, monolithic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

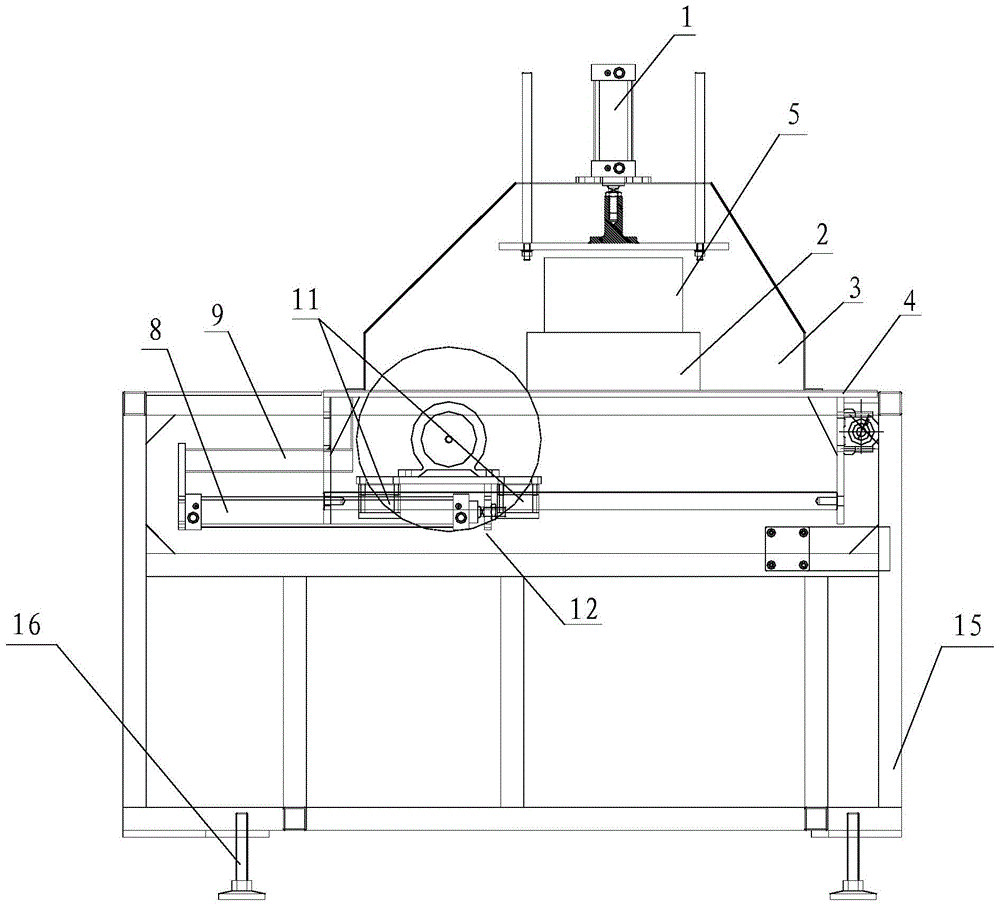

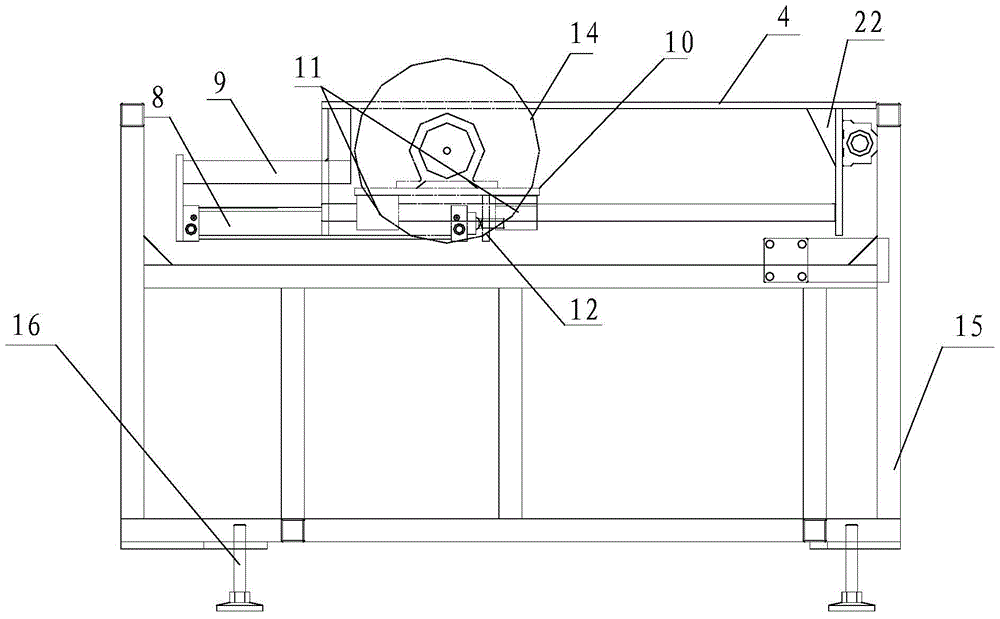

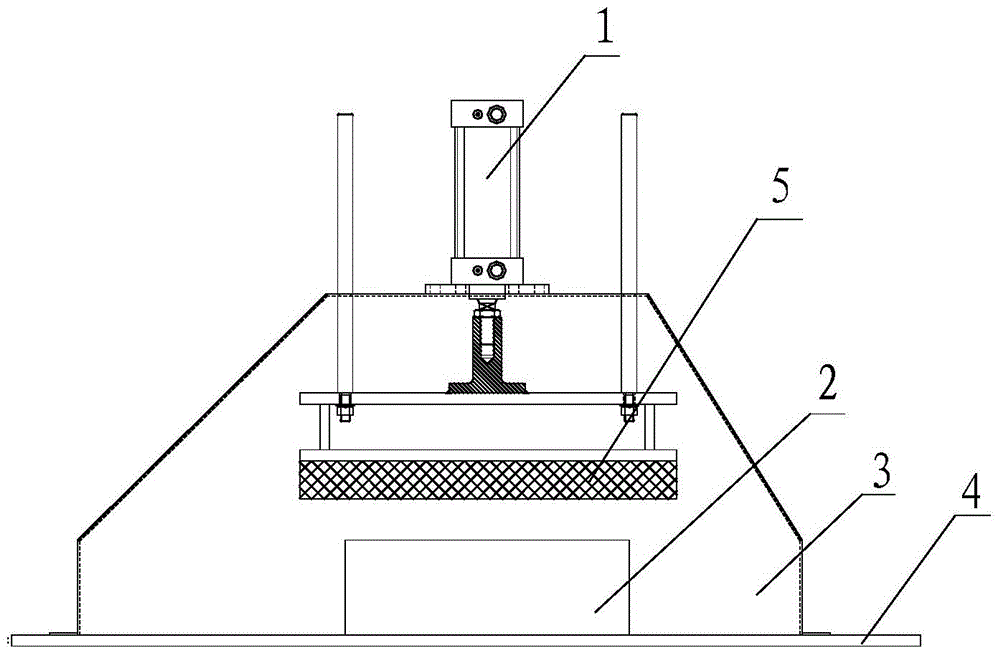

[0030] Such as figure 1 The automatic cutting machine for nylon heat insulation strip production line shown includes a workbench support 15, the lower end of the workbench support 15 is provided with a foot 16, one side of the workbench support 15 is fixedly connected with front and rear cylinders 17, and the cylinder rods of the front and rear cylinders 17 Be connected with guide plate 21, the top of guide plate 21 is connected with connecting plate 19, and the two ends of connecting plate 19 are fixedly connected with slide block 20 respectively, and two slide blocks 20 are interspersed on a front and back guide rod 18, front and back cylinder 17 The function is to advance the nylon insulation strip and enter the feed port 2.

[0031] The top faces of the two slide blocks 20 are provided with a panel 4, the panel 4 is provided with a strip gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com