Quenched steel part dry state and wet state coordinated cutting method

A technology for cutting and processing hardened steel, which is applied in the field of dry and wet cutting of hardened steel parts, which can solve problems such as the adverse effects of cutting tools and machined parts accuracy, so as to avoid scrap rate, reduce processing difficulty, and improve personnel efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

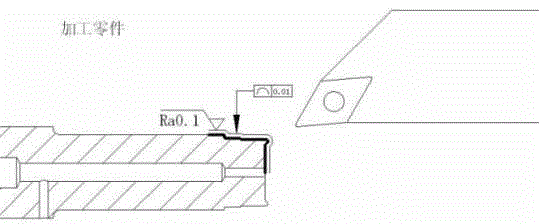

[0021] like figure 1 As shown, a hardened steel part requires HRC: 64-67 for hardness, 0.01 mm for profile, and Ra: 0.1 μm for surface roughness. Usually hard turning requires HRC: 55-64 for hardened steel, machining accuracy IT5 level, surface roughness Ra≤0.4μm. Obviously, the requirements for the hardened steel parts processed this time are relatively high.

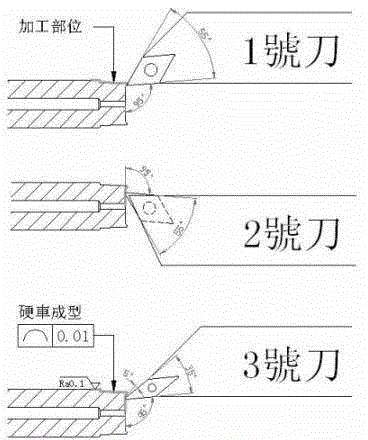

[0022] like figure 2 As shown in the figure, in order to improve the quality of the parts, the machine tool used this time adopts a hydrostatic spindle, and the clamping device adopts three claws after quenching and tempering to clamp the parts; a higher hardness turning tool holder is used, in order to maximize the hard turning system rigidity and accuracy.

[0023] The specific processing method is as follows:

[0024] The first step: write the processing program: mainly to set the tool path of the CNC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com