Light segmentation method, laser-based cutting method, equipment and system

A light and polarized light technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inconsistent output light energy in the optical path and difficult film layers of the beam splitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

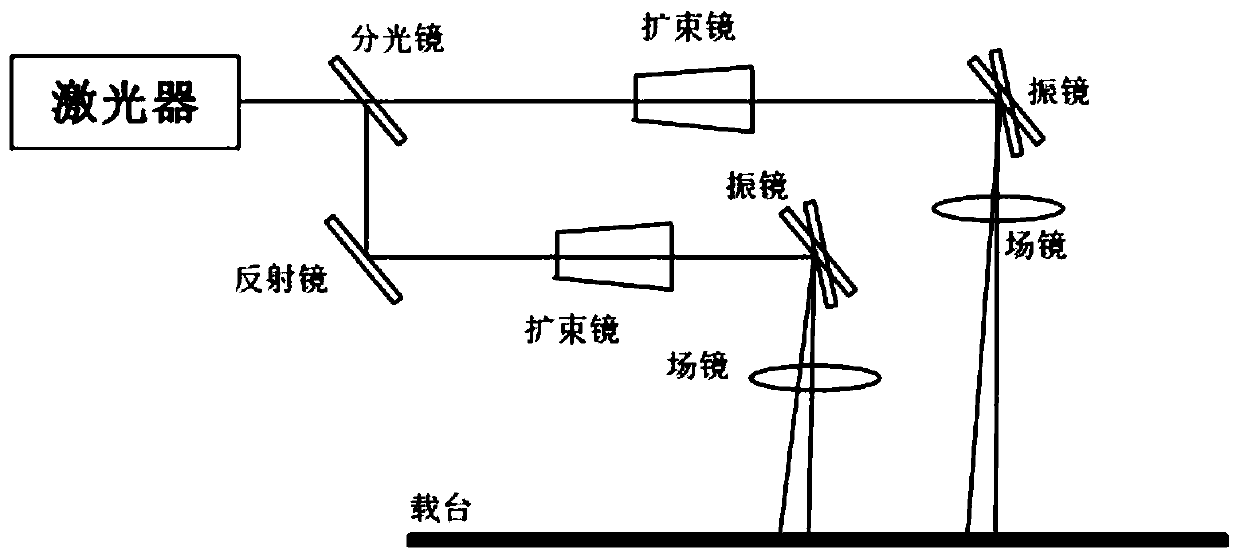

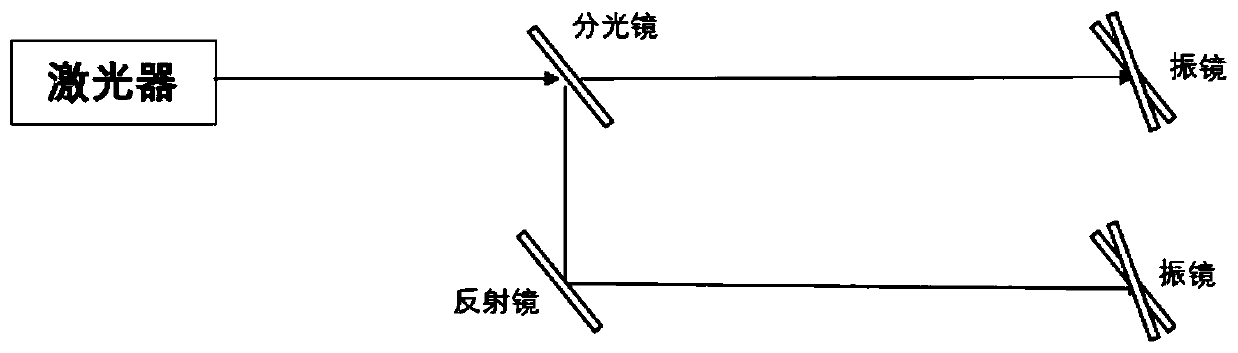

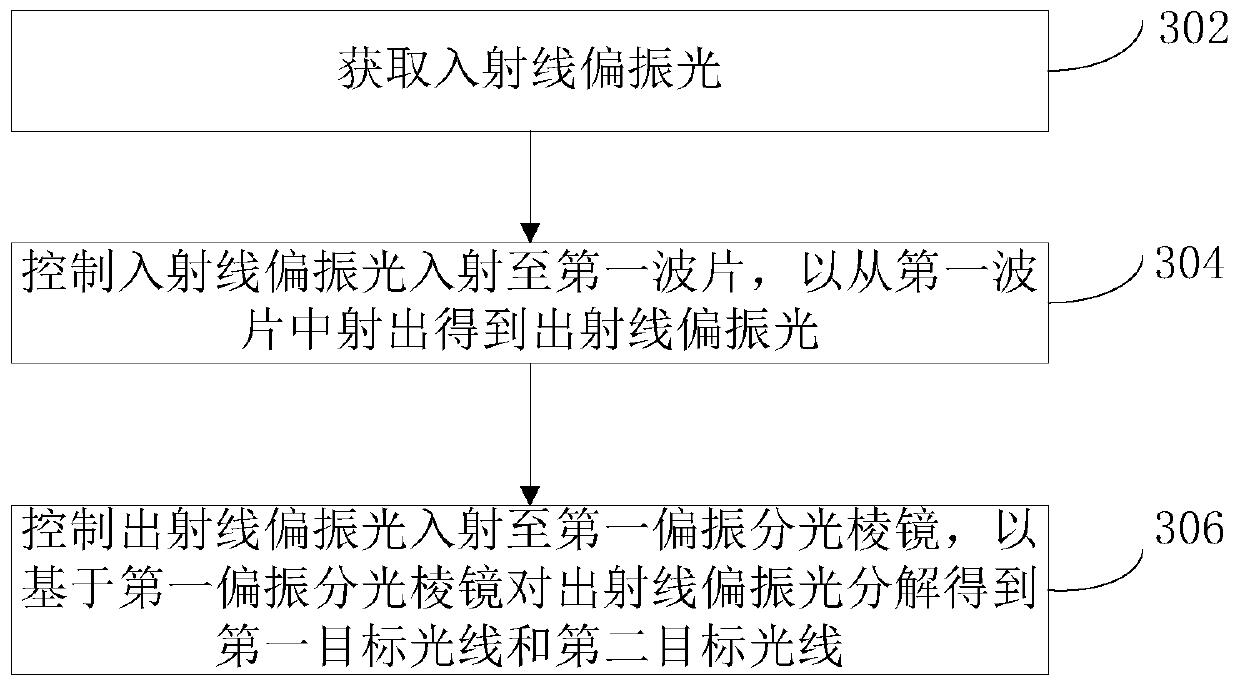

[0038] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

[0039] The technical solutions provided by various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] For the beam splitter (Beam Splitter), it splits the light through the surface coating. However, on the one hand, it is difficult for the film layer to achieve the standard 50:50 ratio of light splitting. Therefore, the output light energy of the two optical paths is inconsistent and the ratio is different. Larger, when laser cutting, the cutting effect is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com