An online installation method of rolling mill in existing rolling line

A technology with existing rolling lines and installation methods, applied in the direction of metal rolling stands, metal rolling, metal rolling, etc., can solve the problems that affect the construction period, increase the installation cost, and cannot guarantee that the existing rolling lines cannot be stopped. Construction requirements and other issues, to achieve the effect of high installation efficiency, convenient operation and reduced installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

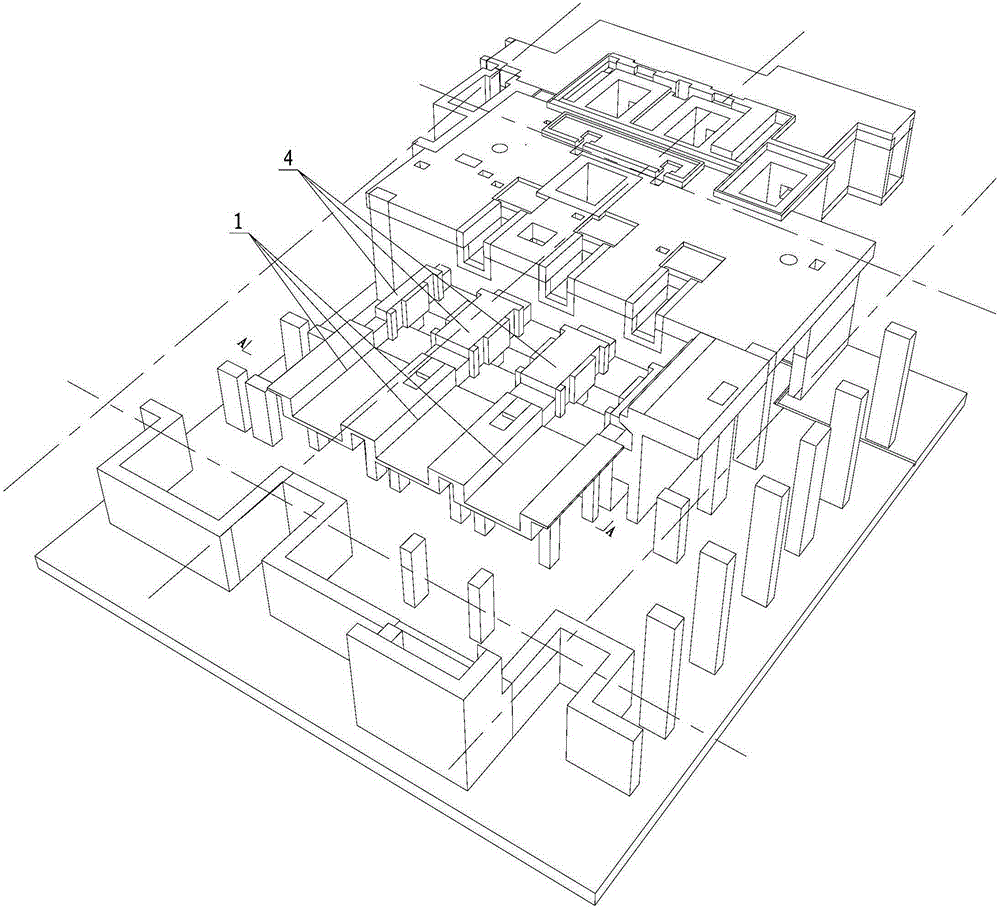

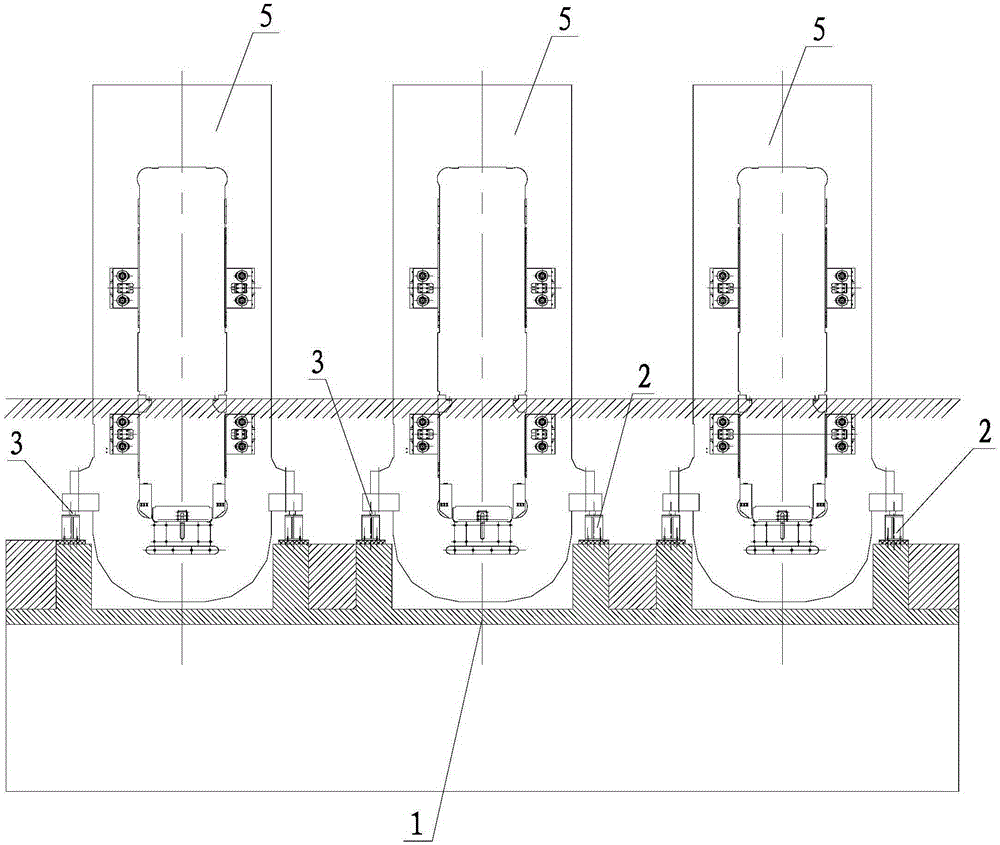

[0015] Such as figure 1 , figure 2 Shown is an on-line installation method of an existing rolling mill with low construction cost, high efficiency and convenient installation and operation provided by the present invention. The online installation method includes the following steps

[0016] 1) Remove the concrete structure in the underground space, and use the dust-free wire saw cutting method to remove the complex underground space concrete structure on the existing rolling line that needs to be added to the rolling mill;

[0017] 2) To construct the load-bearing structure, first place the steel bars of the load-bearing structure at the position of the roll changing device on the existing rolling line that needs to be added to the new rolling mill removed in step 1), implant the steel bars of the load-bearing structure by chemical planting and bind them into shape, and then Then support the pouring formwork on the outer side of the bound and formed steel bar, and then pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com