Laser measurement marking-off cutting method for big-width plate

A laser measurement and cutting method technology, applied in the field of plate processing, can solve the problems of poor precision and low efficiency of manual line drawing, and achieve the effect of high precision, great expansion potential and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

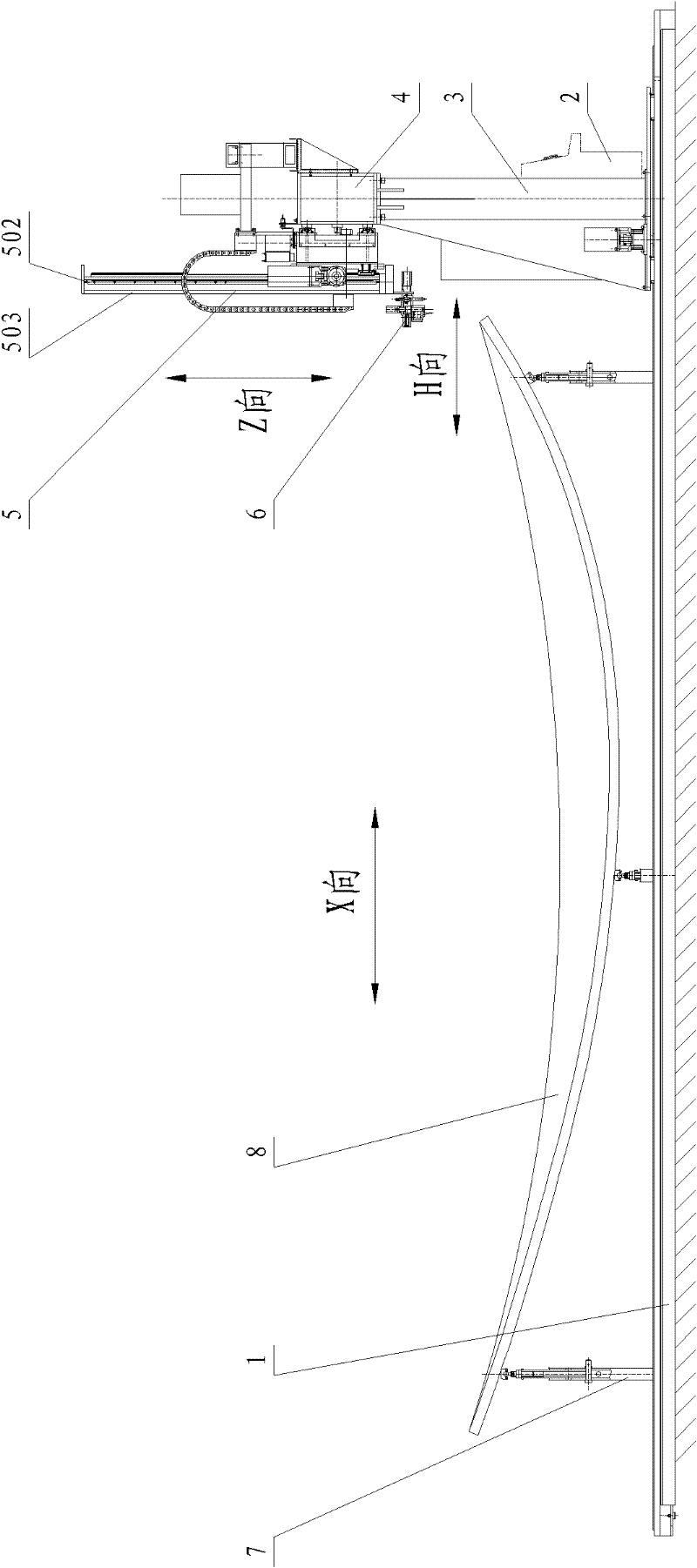

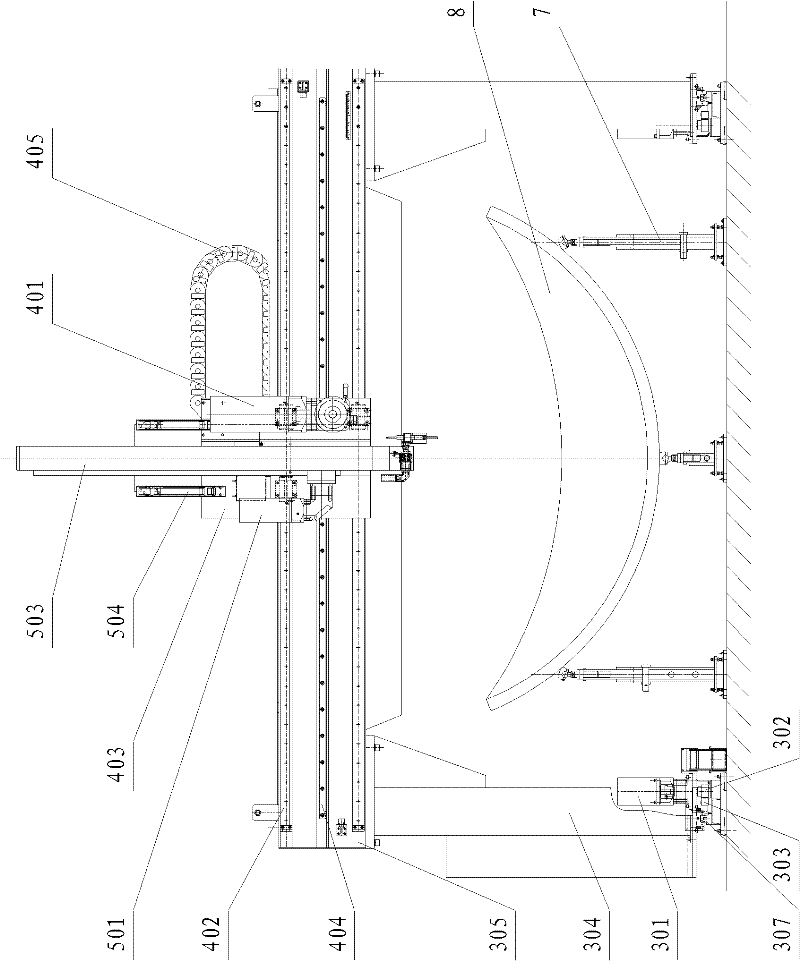

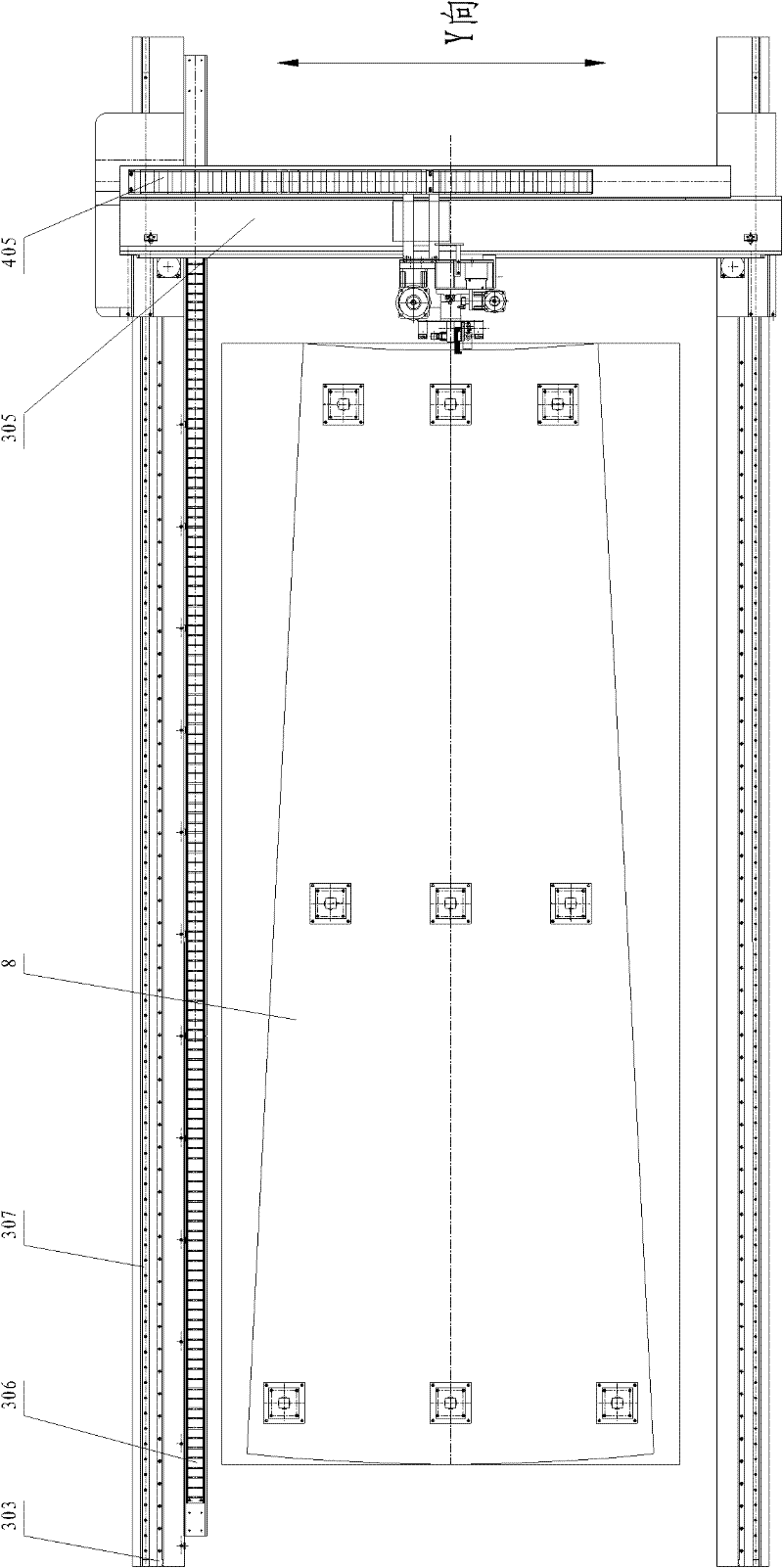

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] The specific steps of the laser measuring and drawing line cutting method of the present invention are:

[0031] A. Hoist the workpiece to be cut on the workbench, use the camera installed on the five-axis gantry type measuring line cutting machine to scan the surface of the workpiece, and obtain a series of coordinate data of the surface feature points of the workpiece. The camera follows the five-axis gantry type The measuring and drawing line cutting machine has three degrees of freedom of movement in X, Y and Z directions;

[0032] B. Use the M file written by MATLAB software to perform differential compensation operation on the obtained feature point coordinate data to fit the workpiece outline, and compare the fitted outline with the theoretical model;

[0033] C. Determine the transformation relationship between the machine tool coordinate syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com