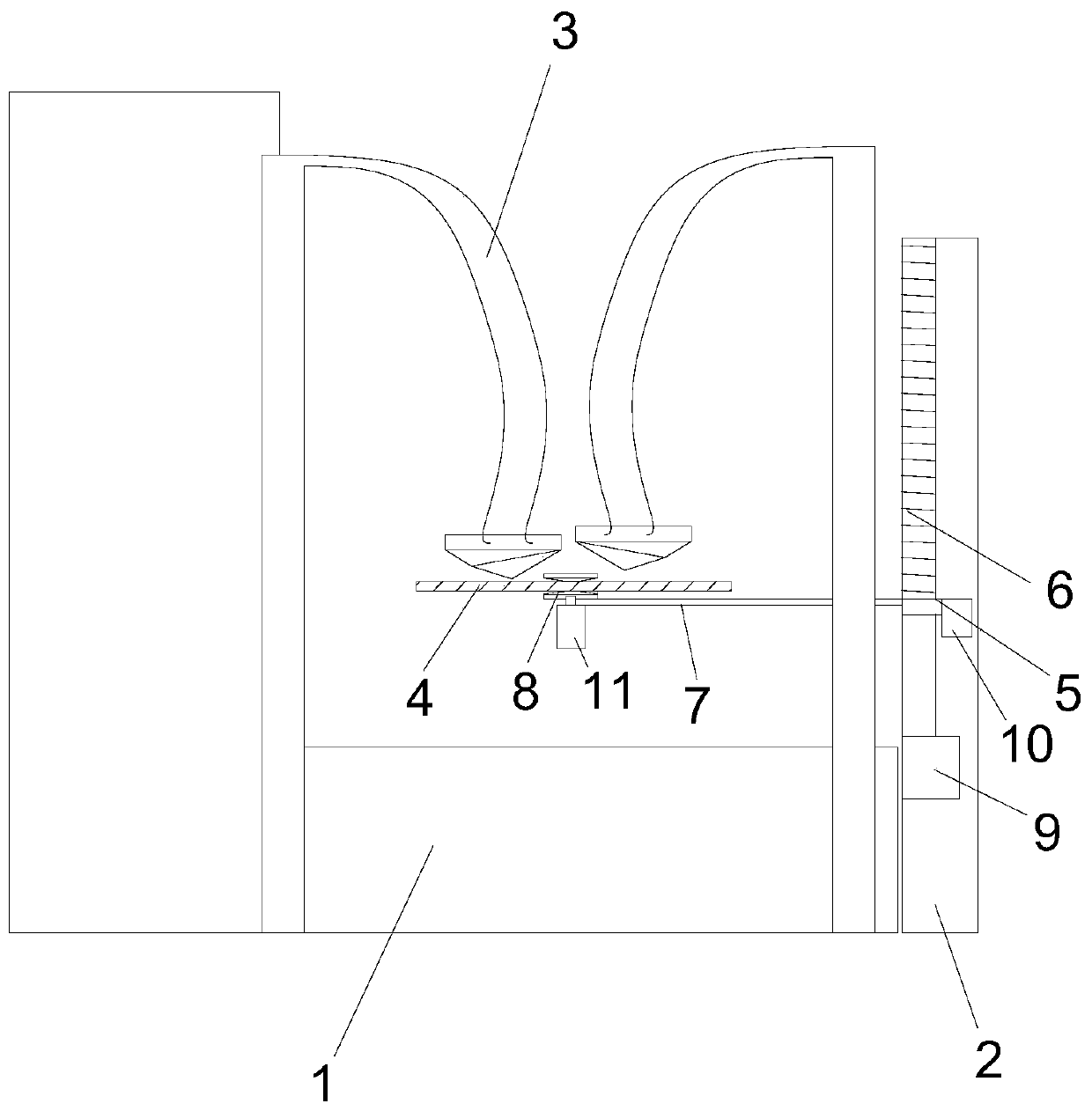

Processing method and processing device for multi-hole circular disk part

A processing method and processing device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to achieve high-precision three-dimensional processing and cannot replace multi-station processes, etc., to achieve three-dimensional processing, Efficiency improvement, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The processing method of the porous disc part in the present invention comprises the following steps:

[0038] S1: Transform the 3D model drawing of the porous disc part into a two-dimensional engineering drawing of the key surface, and use UG software to construct the 3D model of the porous disc part. According to the 3D model, the positive six-sided view of the porous disc part is generated, and the four orthographic views corresponding to the side of the porous disc part are sorted to obtain the side processing plan. Through the UG software, the tool path trajectory is quickly generated, and the process plan of the porous disc part is efficiently designed, which significantly improves the efficiency of the part from design to CNC machining.

[0039] S2: Set the tool path of the CNC machine tool according to the two-dimensional engineering drawing of the key surface, and set the tool path according to the front, back and side processing plan.

[0040] S3: Set the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com