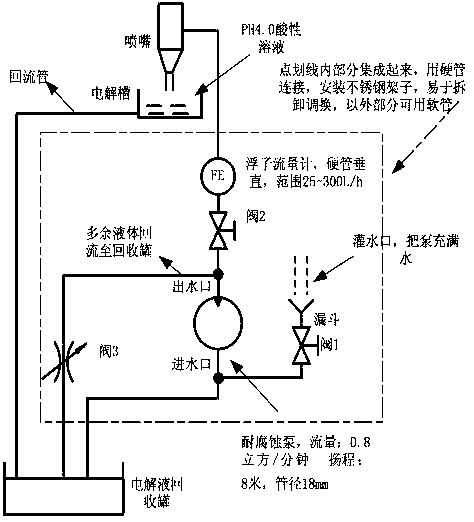

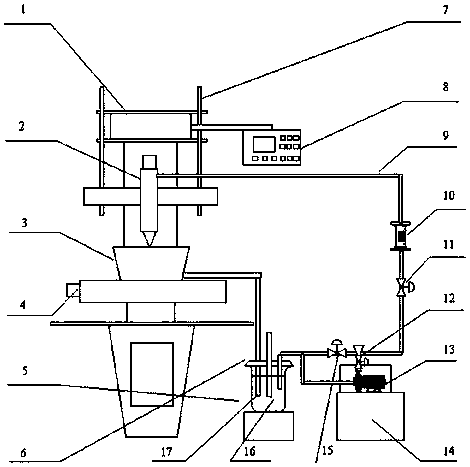

A Simple Jet Electrodeposition Experimental System

An experimental system, the technology of jet electricity, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of high cost, system combination accuracy and performance can not meet the design requirements and effects, time-consuming and labor-intensive, etc. Operation and maintenance, the effect of simple and easy-to-learn operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

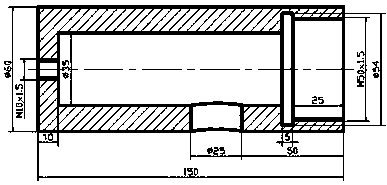

[0038] Example 1: The size of the test piece 304 stainless steel plate is 100mm×10mm×1mm, and the copper deposition layer can be prepared by using the processing equipment, and the operation steps are as follows.

[0039] 1. Clean the system. Before the first use, each circulation link of the system must be cleaned with distilled water to keep the processing environment clean.

[0040] 2. Open the dust cover of the electrolyzer. When the system is not used for a long time, the electrolytic cell should be covered with a dust cover to avoid external pollution.

[0041] 3. Configure the electrolyte. The composition and process parameters of the electrolyte in the present embodiment are respectively:

[0042] CuSO 4 ·5H 2 O 250g / L, 98% concentrated sulfuric acid 50g / L, electrolyte temperature is 25°C. The electrolyte solution is prepared with analytical pure or chemical pure reagents plus distilled water.

[0043] 4. Pour about 4L of the prepared electrolyte into the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com