A three-dimensional self-limiting method for the precise fabrication of silicon nanowire pillars

A silicon nanowire, self-limiting technology, applied in nanotechnology, nanotechnology, semiconductor/solid-state device manufacturing, etc., can solve the problem of inability to achieve three-dimensional (lateral processing, etc.), and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

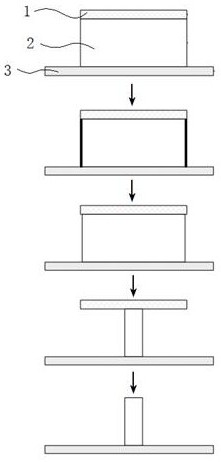

[0038] A three-dimensional self-limiting method for precisely manufacturing silicon nanowire columns, comprising the following steps:

[0039] 1) The formation of a self-limiting oxide layer (Si-O) on the surface of Si; the formation of Si-O bonds is very easy and the thickness is very well controlled. 2 It is easy to form SiO 2 layer and has good self-limiting properties, the thickness is only 1 to several atoms thick, so the thermal reaction is very easy to achieve and has good self-limiting properties;

[0040] 2) removal of excess O atmosphere;

[0041] 3) Selective chemical etching away the SiO layer; gaseous hydrogen fluoride (Vapor HF) can etch SiO 2 , the reaction is: SiO 2 +4HF (gaseous state) = SiF 4 (gaseous)+2H 2 O (gaseous) and does not react with Si, so this step also has good self-limiting characteristics;

[0042] 4) Steps 1) to 3) are repeated to realize precise control of the etching amount.

Embodiment 2

[0044] A method for precisely manufacturing silicon nanowire columns from three-dimensional self-limitation, as in Example 1, such as figure 1 As shown, wherein: the barrier layer 3 (HfO 2 ), thickness 1-10nm, silicon 2 (Si), thickness 50-100nm, hard mask layer 1 (Al 2 o 3 ), with a thickness of 1-10nm; use conventional photolithography to produce lines or columns with a size of 90nm-45nm, and remove the photoresist;

[0045] 1) Then control the substrate temperature (0-200°C) in the vacuum reaction chamber, use O 2 Treatment 1~10s, SiO 2 The thickness is about 3A; then the chamber is evacuated to leave O 2 ;

[0046] 2) Introduce HF gas, process for 1-10s, let HF convert SiO 2Selective etching away, because the fluorides of Hf and Al have very high boiling points, so under the self-passivation of their fluorides, HF will not corrode the masking layer and barrier layer. Then evacuate the residual HF and generated gas in the cavity.

[0047] 3) Repeat the above steps an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com