A method for self-limiting and precise etching of silicon and its special device

A self-limiting and accurate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of inability to achieve three-dimensional (lateral processing, etc., achieve the effect of lateral accurate etching and reduce equipment cost)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

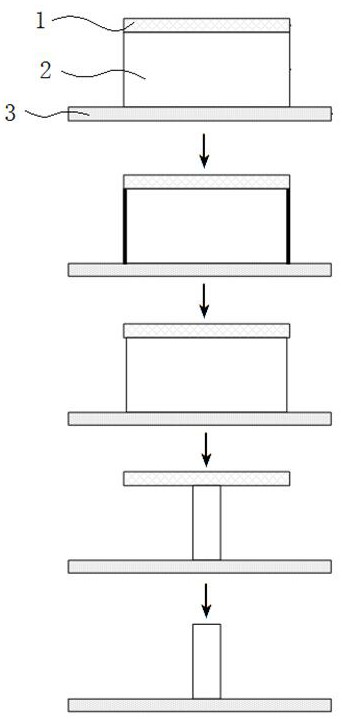

[0036] A method for self-limiting and precisely etching silicon, comprising the following steps:

[0037] 1) Formation of self-limiting oxide layer Si-Br on the Si surface;

[0038] 2) Removal of excess Br-based atmosphere;

[0039] 3) Transfer to high temperature platform to remove Si-HBr;

[0040] 4) Repeat steps 1)~3) to achieve precise control of the etching amount.

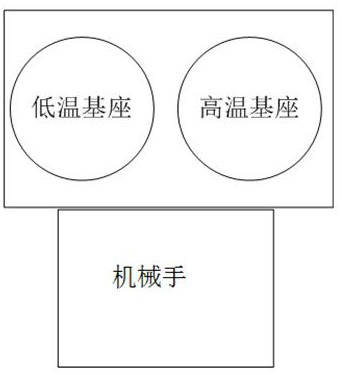

[0041] The special device is similar to ordinary semiconductor vacuum processing equipment, such as figure 1 As shown, there are also transfer modules (manipulators) and process modules. The difference is that there are two bases with different temperatures in the process module, which are low-temperature bases and high-temperature bases. The Br-based treatment on the surface of Si is carried out on the low-temperature base. (step 1), 2)), after completing the corresponding steps, it is transported by the robot to the high-temperature base to remove the SiBrx product (step 3)). Cycle through both pedesta...

Embodiment 3

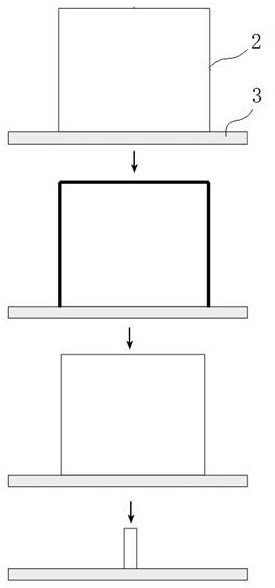

[0054] On the basis of Embodiment 1, the hard mask is omitted, such as image 3 As shown, but the height compensation should be calculated in advance, and the expected nanoscale lines or columns can also be obtained, and the precise nanoscale structure can be obtained without advanced photolithography technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com