Method for regulating pore size of molecular sieve and application thereof

A molecular sieve and pore size technology, which is applied in the field of porous materials, can solve the problems that the size of the molecular sieve pores cannot meet the requirements of natural gas for helium extraction, cannot effectively separate helium and hydrogen, and takes a long time to synthesize molecular sieves. overly good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

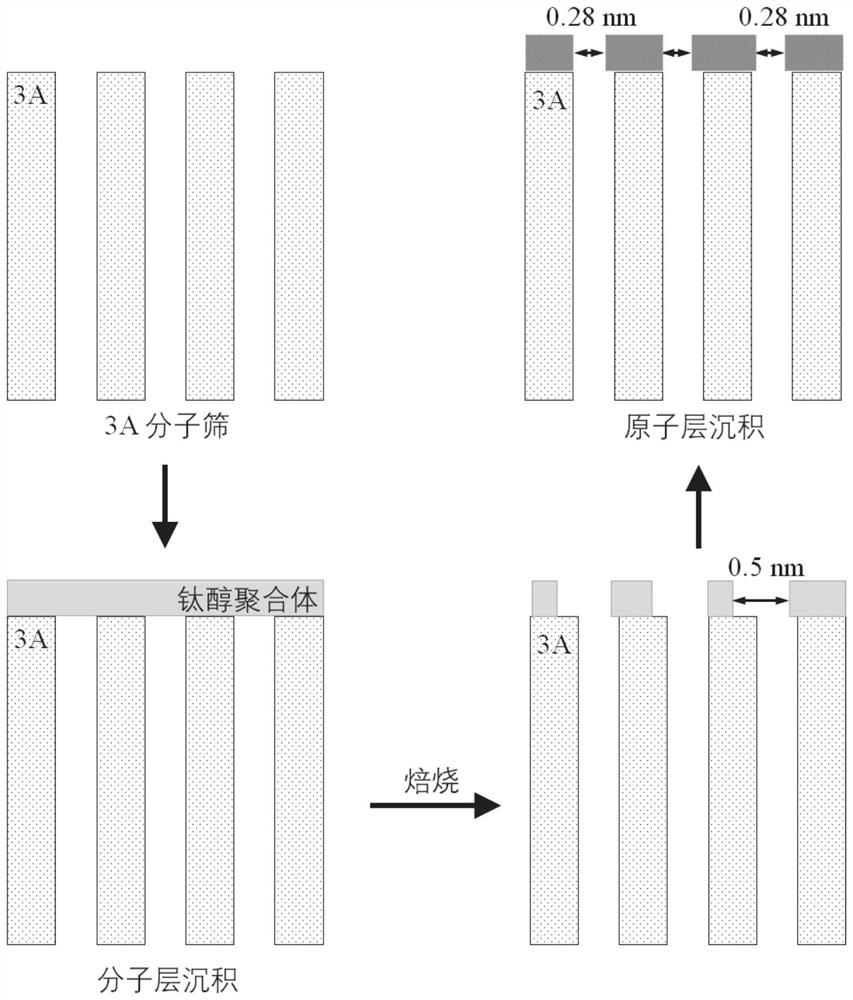

Embodiment 1

[0072] (1) Weigh 1 gram of 100-120 mesh 3A molecular sieve and place it in the cavity of molecular layer deposition. Keep the temperature of the cavity at 100°C, and pulse titanium tetrachloride with a pulse time of 0.3s. The titanium tetrachloride was held in the chamber for 60 seconds after the pulse was completed, and then purged with nitrogen for 60 seconds. Then, pulse ethylene glycol into the cavity with a pulse time of 0.3 s. Ethylene glycol was kept in the chamber for 60 seconds after the pulse was completed, and then purged with nitrogen for 60 seconds. Repeat the above process 30 times.

[0073] (2) The material obtained in step (1) is placed in a tube furnace, and pure oxygen is passed through, and the flow rate is controlled to be 60 mL / min. The temperature was raised to 200°C at 2°C / min for 60 minutes and then to 500°C at 0.5°C / min for 4 hours.

[0074] (3) The material obtained in step (2) is placed in the cavity of atomic layer deposition. Keep the temperat...

Embodiment 2

[0077] The method for regulating the pore size of the molecular sieve is the same as that of Example 1, except that 4A molecular sieve is selected.

Embodiment 3

[0079] The method for regulating the pore size of the molecular sieve is the same as in Example 1, except that 5A molecular sieve is selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com