Controlled synthesis process of functionalized ordered macroporous (less than or equal to 1mm) graphite rotor for aluminum alloy refining

A technology of graphite rotor and synthesis process, applied in additive processing, additive manufacturing, etc., can solve the problems of low hydrogen removal efficiency, large bubble diameter, etc., and achieve the effects of improving pass rate, eliminating thermal stress, and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

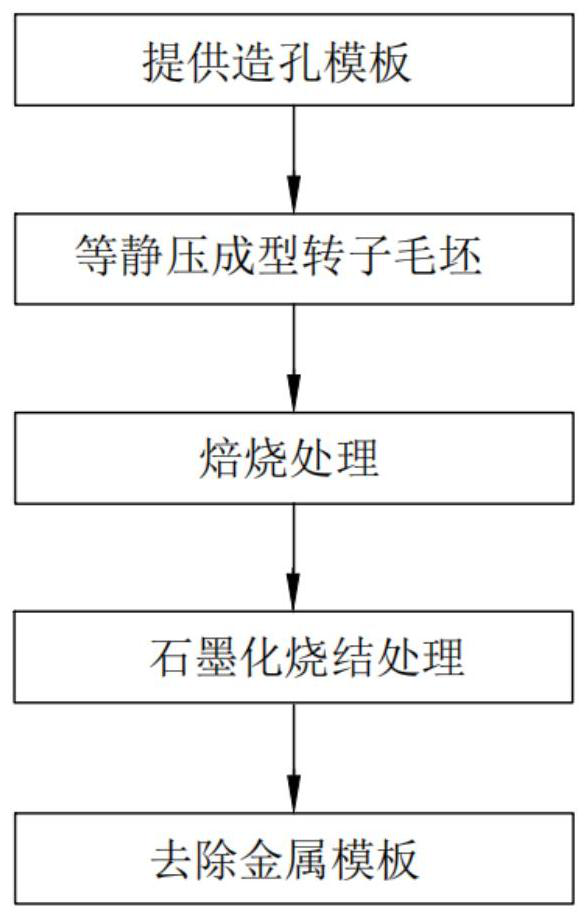

[0128] Embodiment 1 of the present invention provides a control synthesis process for a functionalized ordered macroporous (≦1mm) graphite rotor for aluminum alloy refining, which includes the following steps:

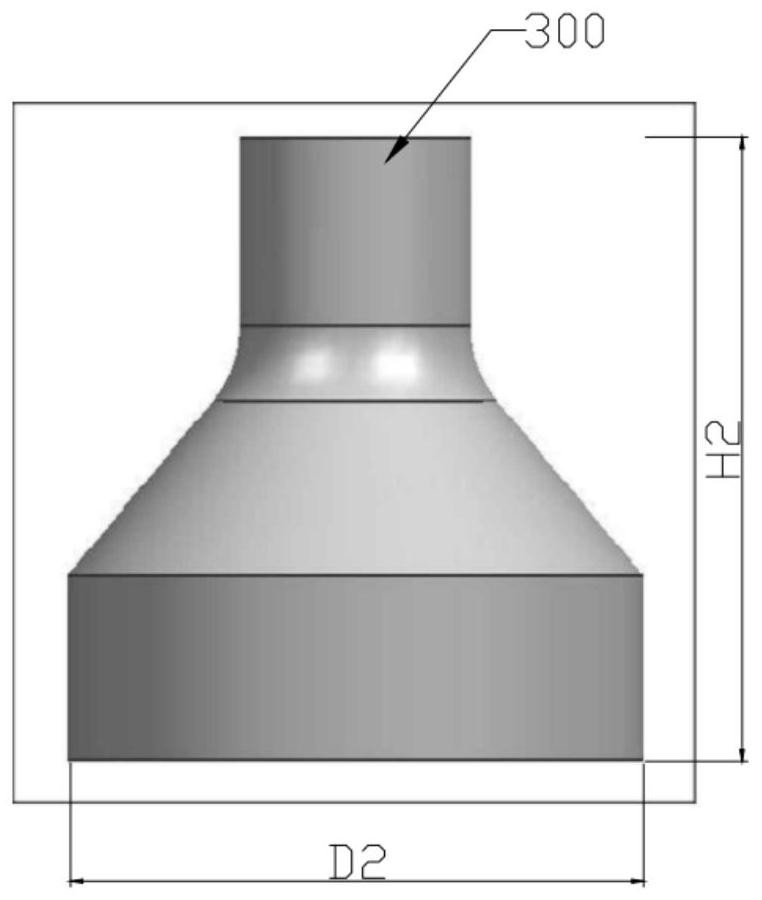

[0129] In step S1, the hole-making template 100 is provided, and the hole-making template 100 is formed by 3D printing technology. Specifically, the hole-making template 100 may include the following steps:

[0130] Step S11, according to the size parameters of the graphite rotor to be fabricated, determine the size parameters of the hole-making template 100, specifically, it includes the following steps:

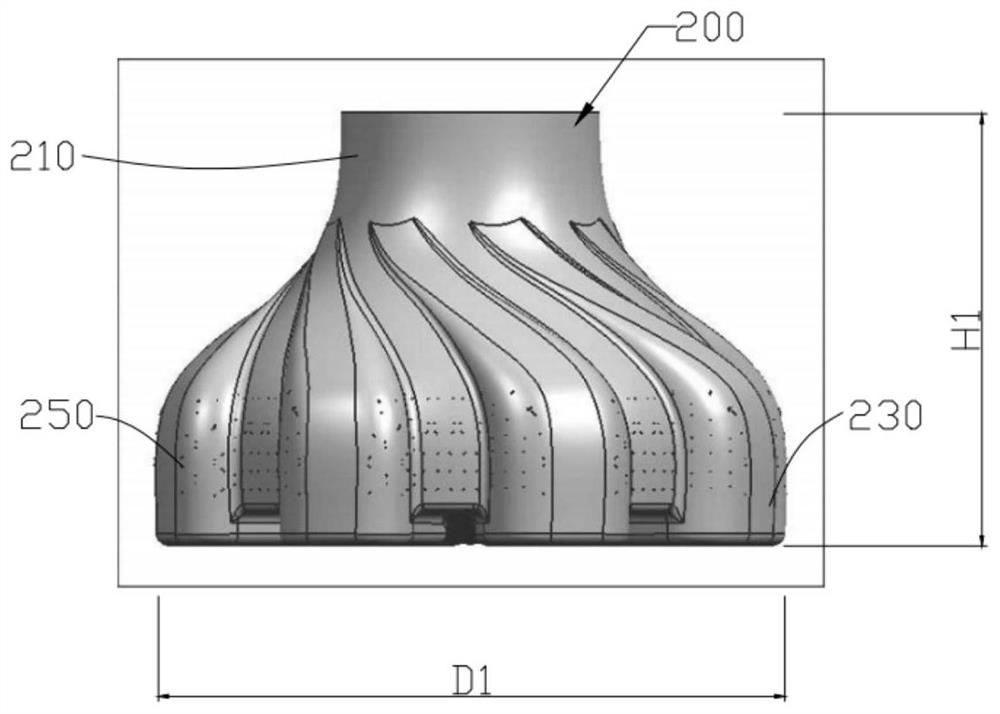

[0131] Determine the overall size of the graphite rotor blank according to the final size parameters of the graphite rotor: specifically, according to the graphite rotor diameter D 1 and the overall height H of the graphite rotor 1 Wait( figure 2 ), and increase the corresponding machining allowance D' and height allowance H' on the surface of each outline of the...

Embodiment 2

[0159] Embodiment 2 of the present invention provides a controlled synthesis process of a functionalized ordered macroporous (≦1mm) graphite rotor for aluminum alloy refining, comprising the following steps:

[0160] Step S1, providing a hole-making template 100: the structure of the hole-making template 100 is the same as that of Embodiment 1, and is not repeated here for the sake of omission of space. The hole-making template 100 is formed by 3D printing technology, which may specifically include the following steps:

[0161] Step S11, according to the size parameters of the graphite rotor to be fabricated, determine the size parameters of the hole-making template 100, specifically, it includes the following steps:

[0162] Determine the overall size of the graphite rotor blank according to the final size parameters of the graphite rotor: according to the diameter D of the graphite rotor 1 and the overall height H of the graphite rotor 1 Wait( figure 2 ), increase the co...

Embodiment 3

[0190] Embodiment 3 of the present invention provides a control synthesis process for a functionalized ordered macroporous (≦1mm) graphite rotor for aluminum alloy refining, which includes the following steps:

[0191] In step S1, a hole-making template 100 is provided, and the structure of the hole-making template 100 is the same as that of Embodiment 1, and is not repeated here for the sake of omission of space. The hole-making template 100 is formed by 3D printing technology, which may specifically include the following steps:

[0192] Step S11, according to the size parameters of the graphite rotor to be fabricated, determine the size parameters of the hole-making template 100, specifically, it includes the following steps:

[0193] Determine the overall size of the graphite rotor blank according to the final size parameters of the graphite rotor: according to the diameter D of the graphite rotor 1 and the overall height H of the graphite rotor 1 Wait( figure 2 ), add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com