Circular combs for combing machines

A technology of combing machine and circular comb, which is applied in the field of circular combing of combing machines, can solve the problems of inability to realize precise adjustment convenience and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

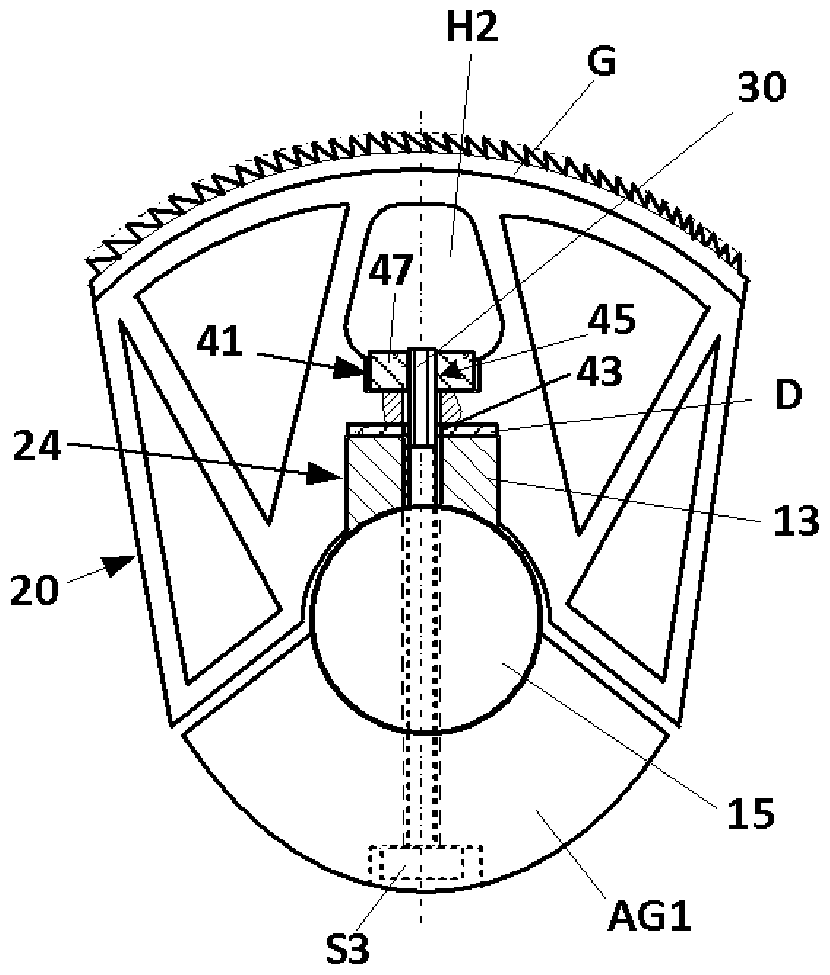

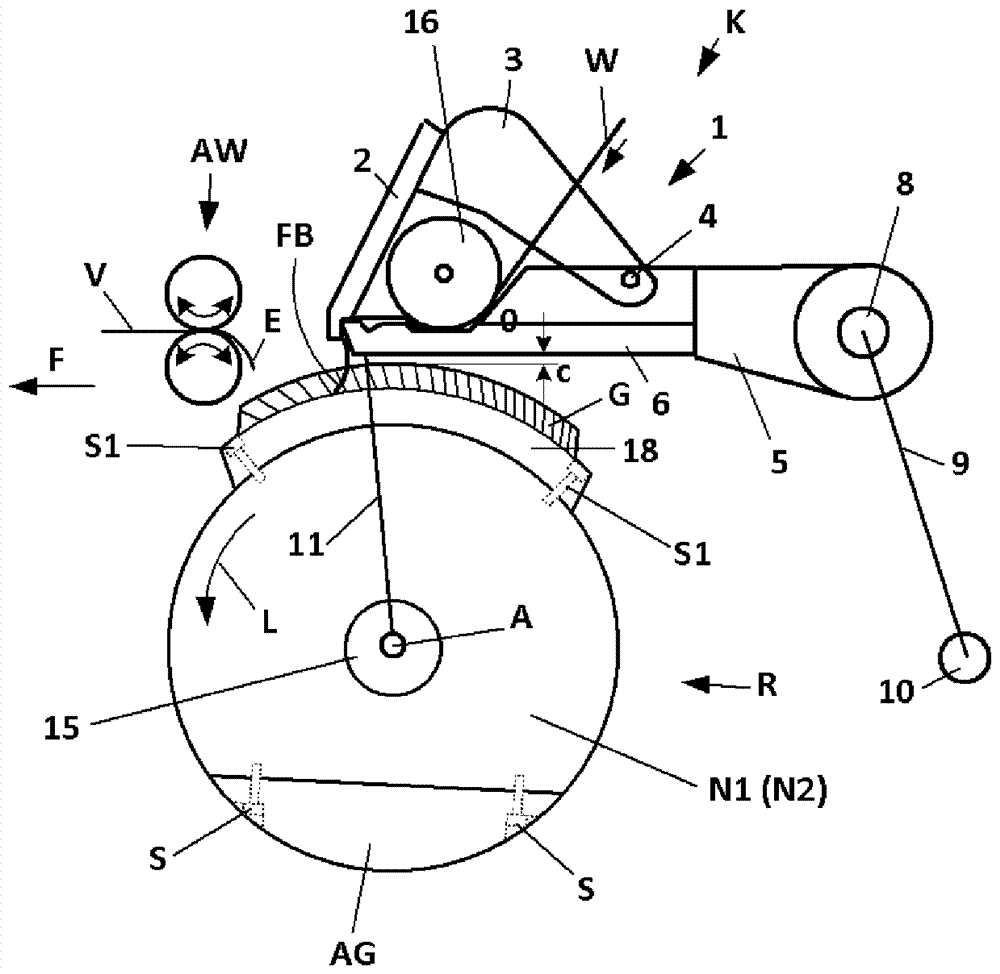

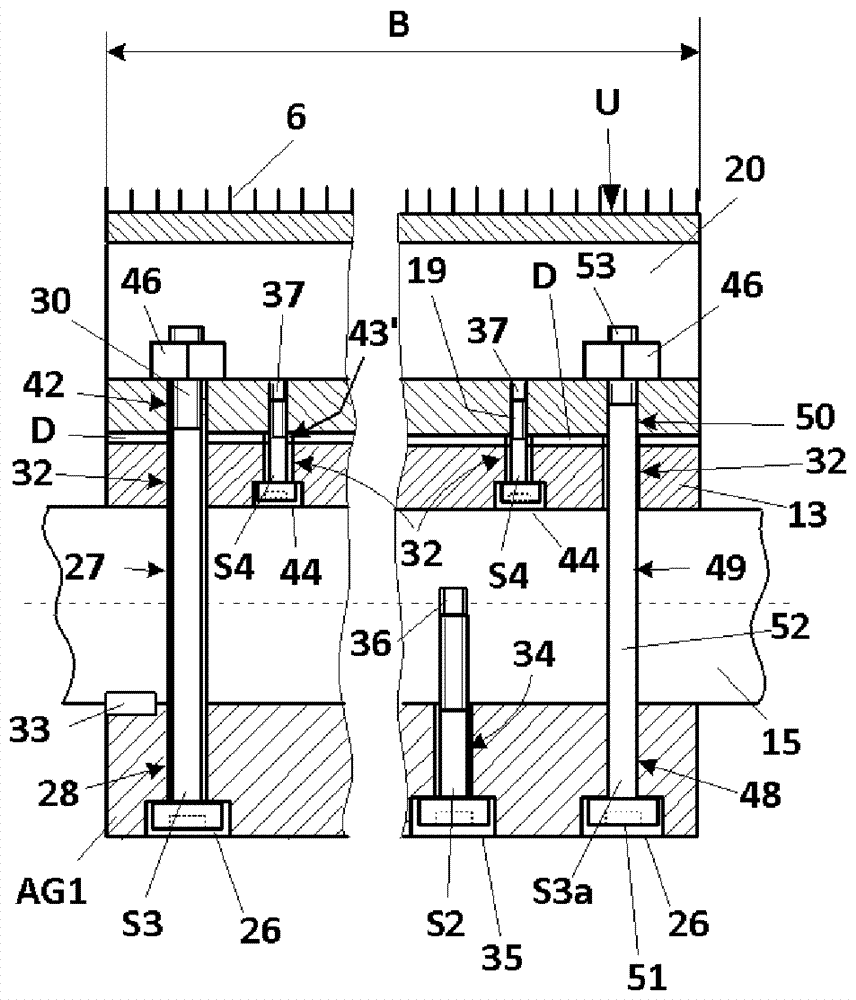

[0040] figure 1 A schematic side view of a combing head K of a combing machine is shown. In known combing machines, for example, eight such combing heads K are arranged side by side. This combing head K, only some of its elements being shown, has a clamp assembly 1 which is mounted in the frame of the combing machine by means of pivoting arms 9, 11 so that said clamp assembly can surround an axis 10 , 15 pivoting reciprocally. Shaft 10 , also called tong shaft, is driven by a drive, not shown in detail, in order to impart a reciprocating movement to tong assembly 1 . The shaft 15 corresponds to the circular comb axis on which the circular comb R is fixed in a fixed rotational relationship. The circular comb shaft 15 with the center axis A is similarly driven continuously or intermittently by a drive not shown. In the known solution shown, the circular comb R fixed on the circular comb shaft 15 below the clamp assembly 1 consists of two hubs N1 permanently fixed on the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com