Template structure for preparing ordered porous graphite rotor and method for forming by adopting 3D (three-dimensional) technology

A porous graphite and template technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve problems such as precise processing of network structures and poor overall rigidity, and achieve precise control of hole spacing, elimination of thermal stress, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

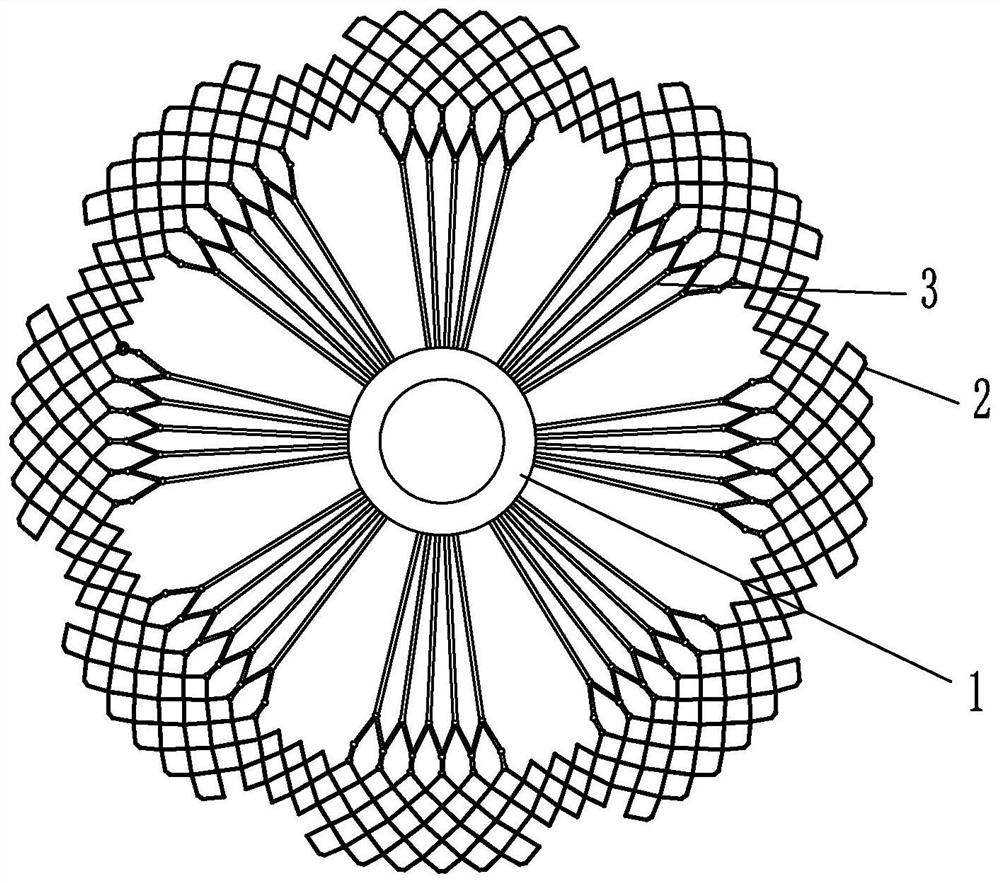

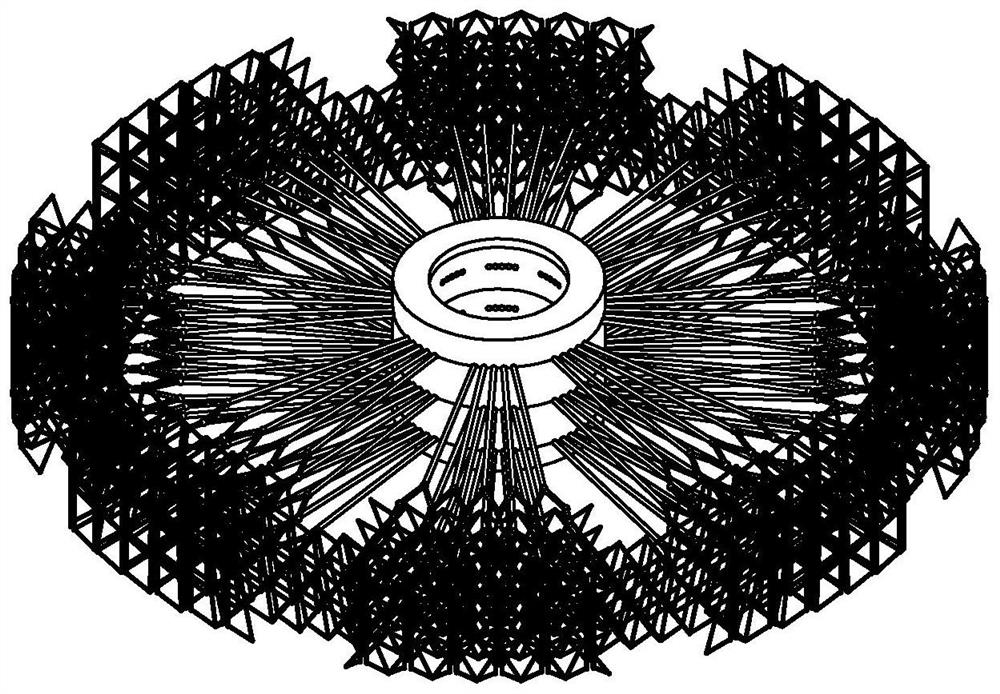

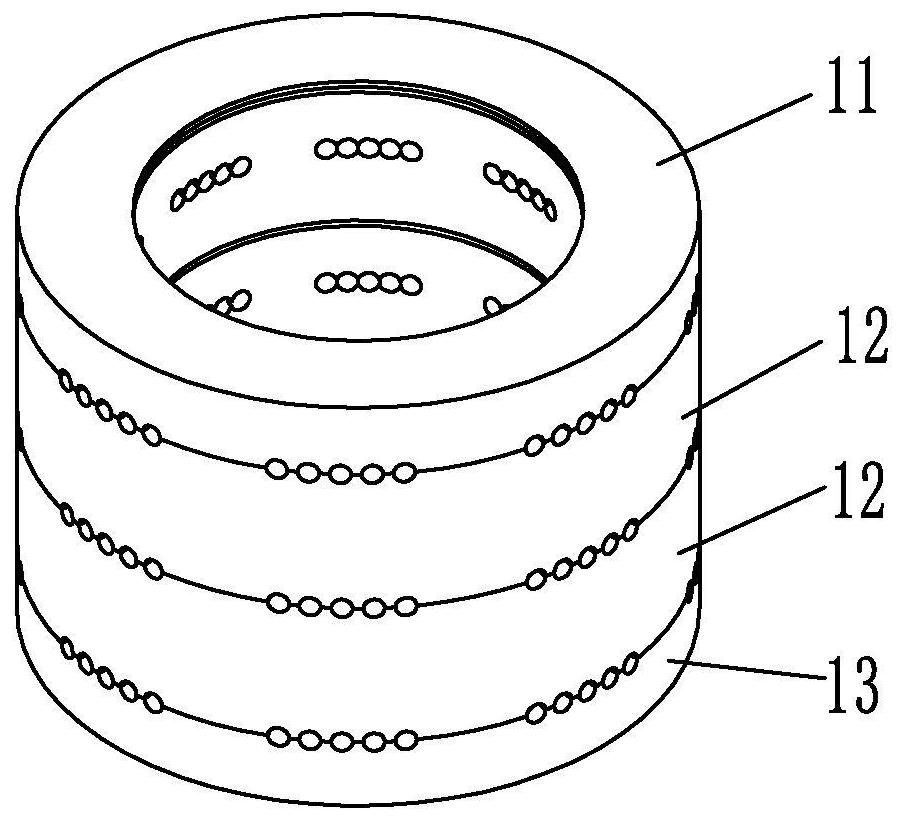

[0051]Example 1: A template structure for preparing an ordered porous graphite rotor, comprising a trunk 1, a circular skeleton 2 and a multi-group branch 3, the trunk is composed of a top hollow cylinder 11, a bottom hollow cylinder 13 and N intermediate hollow cylinders 12 sets, N is 2, the top hollow cylinder and the middle hollow cylinder are opened with a large step hole 14, the inner wall of the lower end of the step hole is provided with a positioning convex column 15, the bottom hollow cylinder has an equal diameter hole, The bottom surface of the top hollow cylinder is opened with a semicircle mounting groove for mounting the branches 17, the middle hollow cylinder and the bottom hollow cylinder are composed of an upper small hollow cylinder 18 and a lower large hollow cylinder 19, the upper small hollow cylinder is provided with a positioning concave column 16, the top surface and bottom surface of the lower large hollow cylinder of the middle hollow cylinder and the top...

Embodiment 2

[0054] Example 2: A method of molding the template structure as described in Example 1 using 3D technology, the process combines the design of a large-size fine network structure of the pore, the use of metal materials and 3D technology to form a large-size fine network structure, the use of photosensitive resin C-UV 9400 material and light curing technology to form the template components, to eliminate the subsequent thermal stress in the preparation process of graphite composite materials, which includes the following steps and process conditions thereof:

[0055] Step 1: Select the "axis tree" structure to build a holemaking template

[0056]According to the geometric characteristics such as graphite rotor nozzle size, distribution location, quantity, internal aperture structure, etc., the "shaft tree" structure is preferably used to construct a template for holeming inside the graphite rotor. Thereinto:

[0057] (1) The central ventilation area connected by the graphite rotor ...

Embodiment 3

[0100] Example 3: A method of molding the template structure as described in Example 1 using 3D technology, the basic steps of which are the same as In Example 2, the difference is that:

[0101] In step 2, the preferred nozzle bore diameter is: 0.5 mm.

[0102] In step 3, the preferred pore volume ratio is 0.03.

[0103] In step 4, the basic unit consists of eight thin rods at an angle α = 50° (critical molding angle) at an angle to the horizontal plane

[0104] In step five, the thin rod diameter of the octahedral element d cylin The value is: d cylin = 0.5 mm。 The diameter of the spherical node d sphere = 2.15 mm。

[0105] In step 10, both the annular skeleton and the branches were prepared by powder made of 18Ni300Fe. The principle of selecting the 18Ni300Fe material is the same as the principle of selecting the TC4 material in Example 1.

[0106] In step 12, if the percentage of pore volume obtained Φ ≦ 0.03, return to step 5 and redesign the shaft tree structure until the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com