A preparation method of a microreactor for controllable screening of particles in fluids

A technology of microreactors and particles, which is applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve the limitations of microreactor screening and separation particle use range, purity and Problems such as screening efficiency, screening and separation of particles and liquid medium characteristics, inability to actively screen particles, etc., achieve fast and efficient screening and separation, increase the scope of use, and facilitate precise regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is to the SiO of different particle sizes in the solution 2 Particles are screened, separated and mixed. First, SiO with a particle size of 5 μm, 10 μm, and 15 μm is prepared. 2 For the particle solution, the concentrations of the three particle sizes are all 0.005mol / L, and then the fabricated microreactor is placed in the container containing the solution.

[0033] A method for preparing a microreactor for controllable screening of particles in a fluid, comprising the following steps:

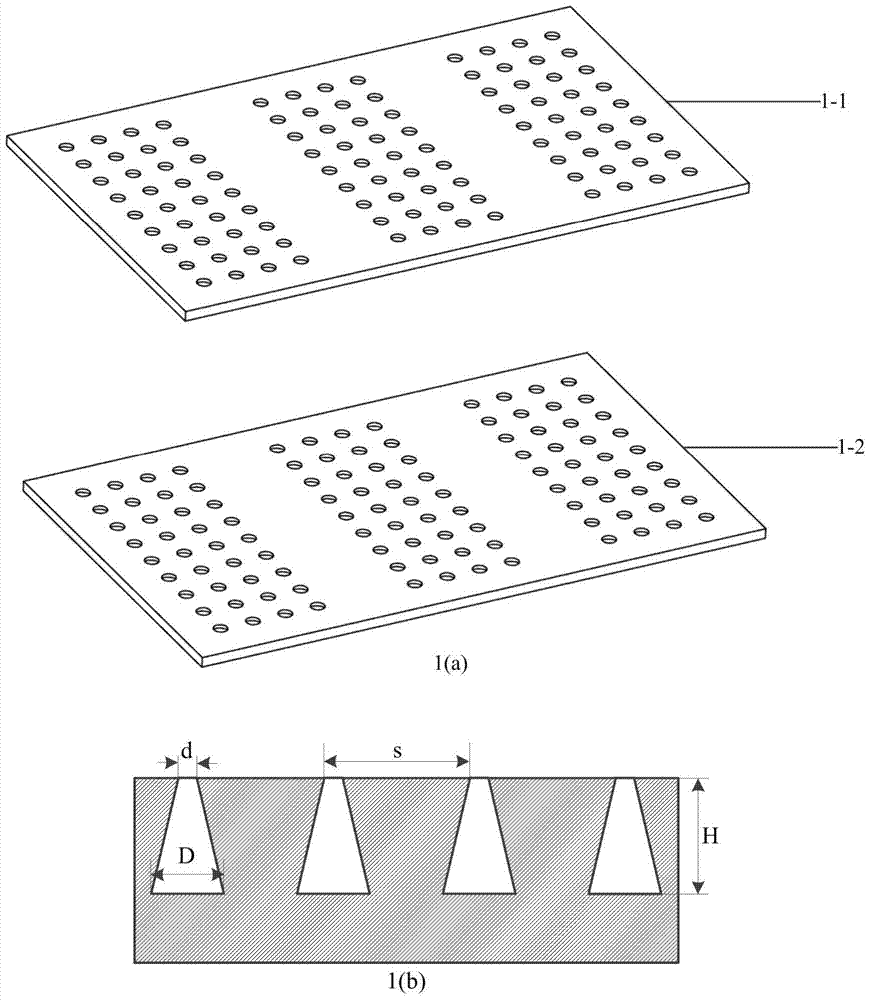

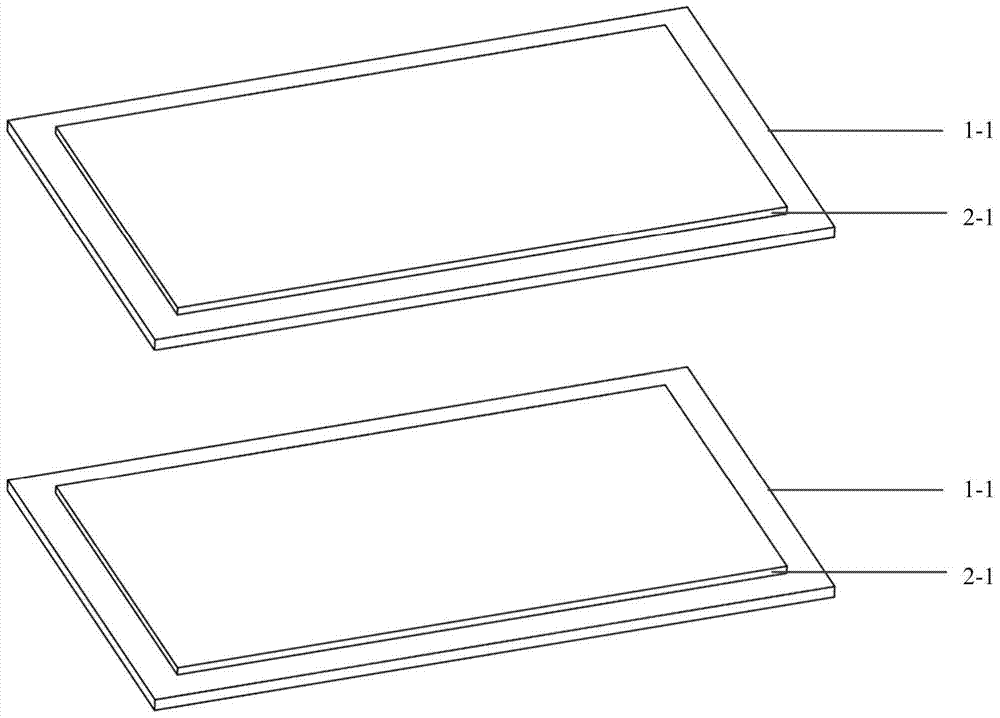

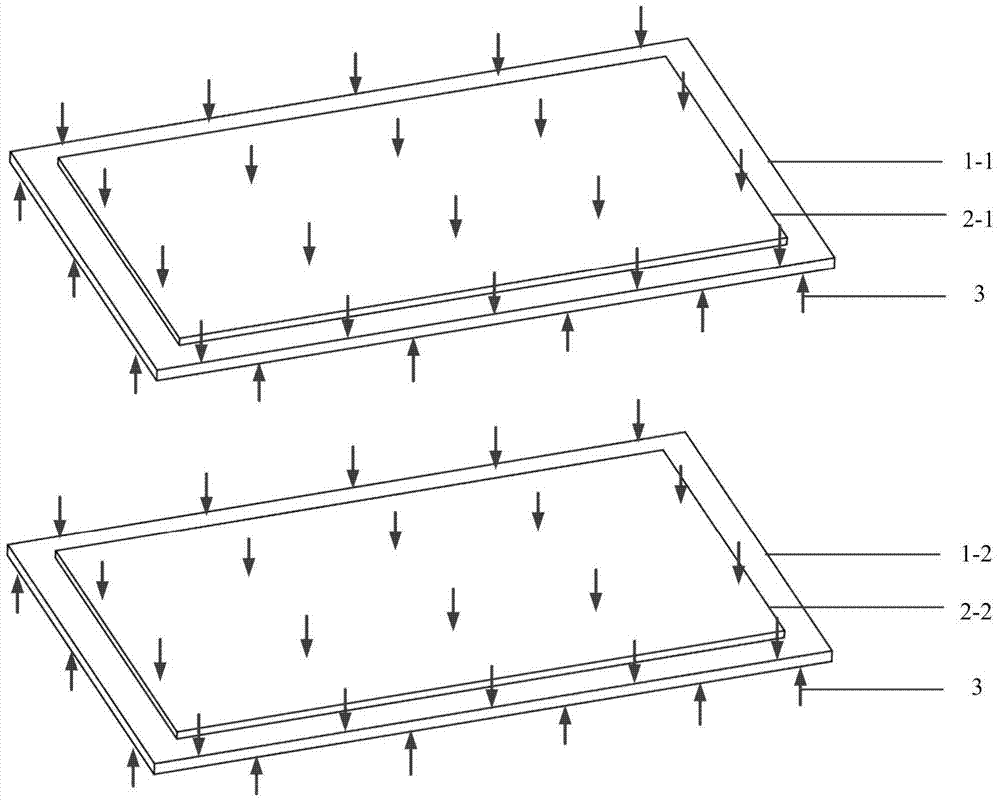

[0034] 1) Refer to figure 1 (a), through photolithography, dry etching and overmolding process to manufacture micron-scale conical flask-shaped hole array polymer separation film, the polymer separation film includes the upper polymer separation film 1-1 and the lower polymer separation film 1 -2, the material of the polymer separation membrane is PDMS; refer to figure 1 (b), the size of the micron-sized Erlenmeyer flask-shaped hole in the polymer separation film is:...

Embodiment 2

[0043] In this example, Co particles with different particle sizes in the solution are screened, separated and mixed. Firstly, Co particle solutions with particle sizes of 20 μm, 50 μm, and 100 μm are prepared, and the concentrations of the three particle sizes are all 0.007 mol / L. The microreactor is placed in the container containing the solution.

[0044] A method for preparing a microreactor for controllable screening of particles in a fluid, comprising the following steps:

[0045] 1) Refer to figure 1 (a), through photolithography, dry etching and overmolding process to manufacture micron-scale conical flask-shaped hole array polymer separation film, the polymer separation film includes the upper polymer separation film 1-1 and the lower polymer separation film 1 -2, the material of the polymer separation film is PUA; refer to figure 1 (b), the size of the micron-sized Erlenmeyer flask-shaped hole in the polymer separation film is: large end diameter D=160 μm, small en...

Embodiment 3

[0054] In this embodiment, PMMA particles with different particle sizes in the solution are screened, separated and mixed. First, PMMA particle solutions containing particle sizes of 60 μm, 90 μm, and 120 μm are prepared. The concentrations of the three particle sizes are all 0.009mol / L, and then the prepared The microreactor is placed in the container containing the solution.

[0055] A method for preparing a microreactor for controllable screening of particles in a fluid, comprising the following steps:

[0056] 1) Refer to figure 1 (a), through photolithography, dry etching and overmolding process to manufacture micron-scale conical flask-shaped hole array polymer separation film, the polymer separation film includes the upper polymer separation film 1-1 and the lower polymer separation film 1 -2, the material of the polymer separation membrane is PDMS; refer to figure 1 (b), the size of the micron-sized Erlenmeyer flask-shaped hole in the polymer separation film is: larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com