Automatic optical fiber laser cutting equipment and cutting method thereof

A technology of cutting equipment and cutting method, applied in laser welding equipment, grinding/polishing equipment, welding equipment and other directions, can solve the problems of affecting accuracy and material cost waste, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

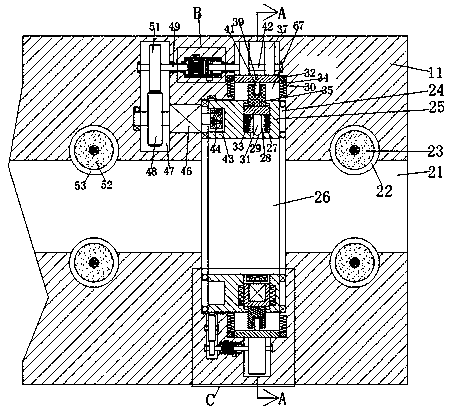

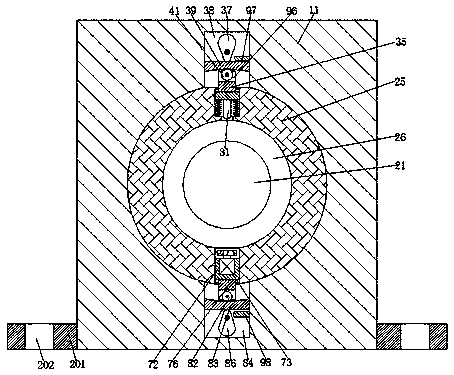

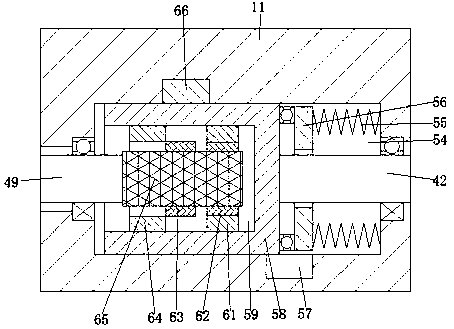

[0020] Such as Figure 1-Figure 4 As shown, an automatic fiber laser cutting device and its cutting method of the present invention include a device main body 11 and a laser cutting device arranged in the device main body 11, and the laser cutting device includes left and right penetrating devices arranged in the The first cavity 21 in the device main body 11, the inner wall of the first cavity 21 is connected with the second cavity 24, and the second cavity 24 is rotated with the first rotary block 25. A third cavity 26 is provided left and right in the first rotary block 25, and a first rotary slot 43 opening to the left is provided in the first rotary block 25, and the first rotary slot 43 is far away from all The inner wall on one side of the third cavity 26 is provided with a gear structure, wherein, the upper end of the left inner wall of the second cavity 24 is fixedly provided with a first motor 46, and the right end of the first motor 46 is powered by a rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com