Washer and method of determining load weight for same

a technology of washing machine and load weight, which is applied in the field of washing machine, can solve problems such as descending achieve the effects of improving the performance of washing machines, accurate amount of water, and precise washing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

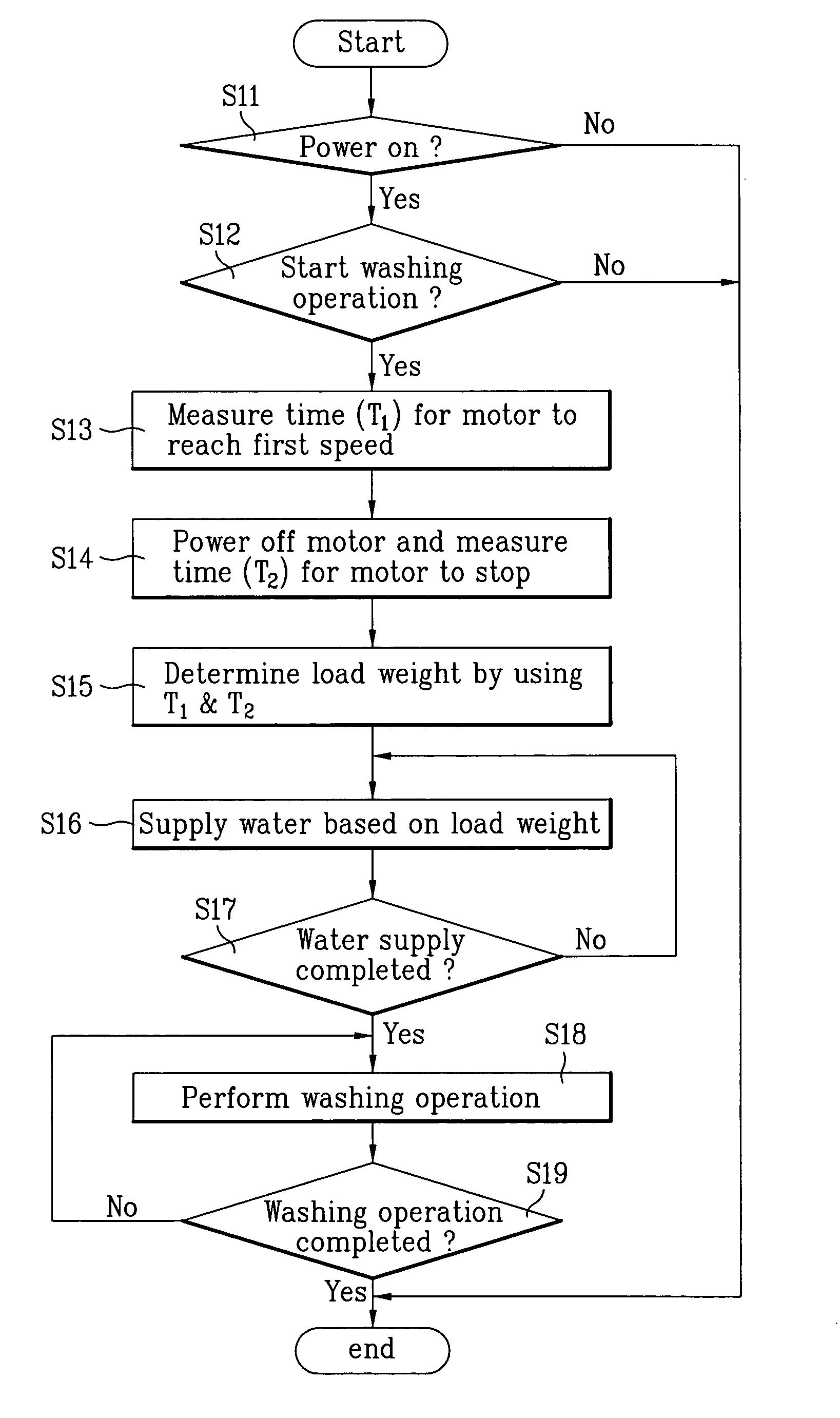

Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

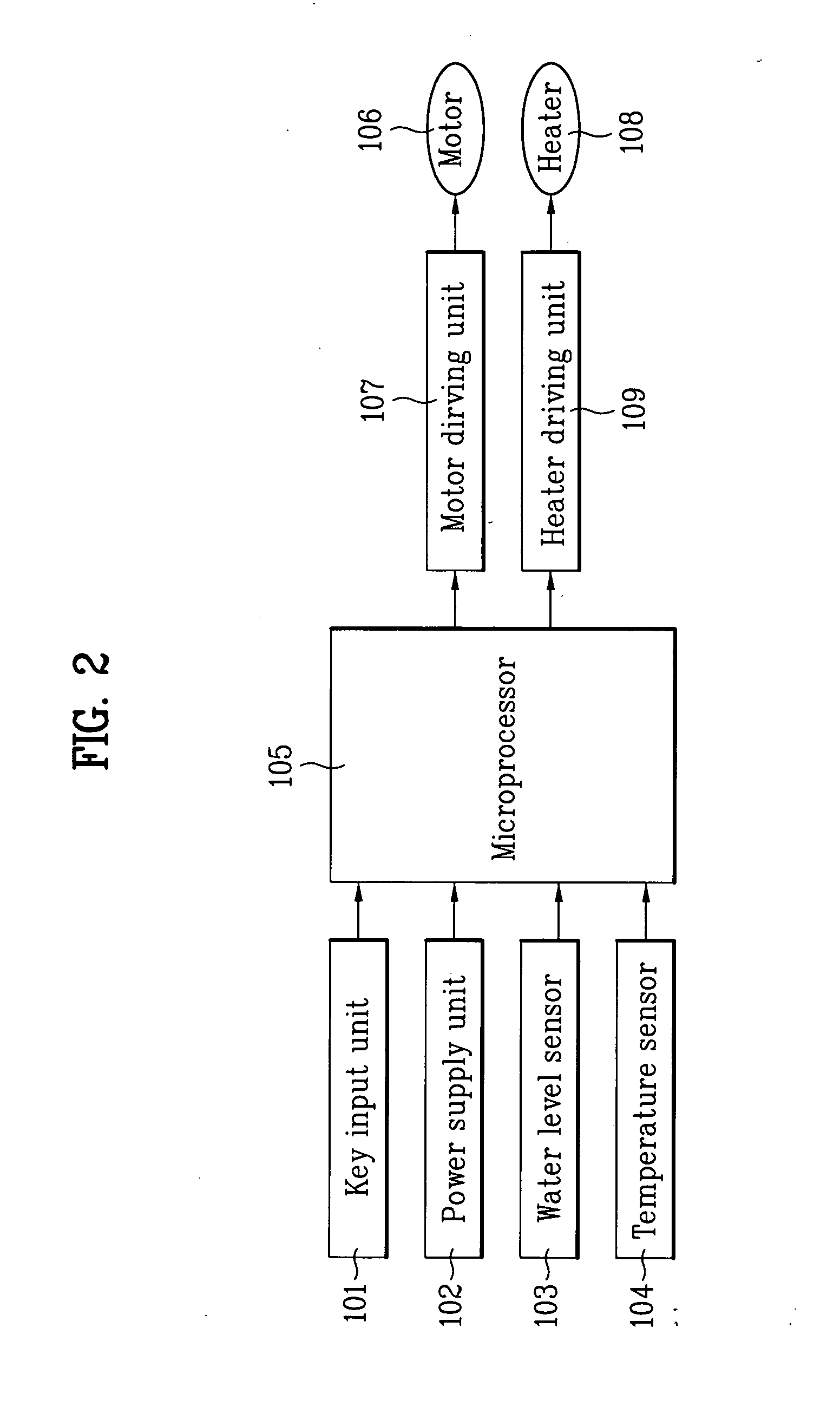

FIG. 2 illustrates a schematic block diagram of a drum washer in accordance with the present invention. The drum washer includes a key input unit 101 which receives an user's command for a washing operation, and a microprocessor 105, which determines a load weight by using the time, T1, during which a motor 106 rotates up to a pre-determined speed, and T2 during which the motor 106 comes to a full stop after the motor 106 is powered off. Then, the microprocessor 105 decides washing operation parameters such as time intervals of washing, rinsing and dehydrating cycles, and a temperature of the supplied water according to the determined load weight.

The washer also includes a water level sensor 103 which senses a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com