S-type acceleration and deceleration control method of numerical control machine tool

A technology of acceleration and deceleration control and CNC machine tools, applied in the direction of digital control, electrical program control, etc., can solve problems such as cumbersome calculations, complicated stage time, and no unified formula solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

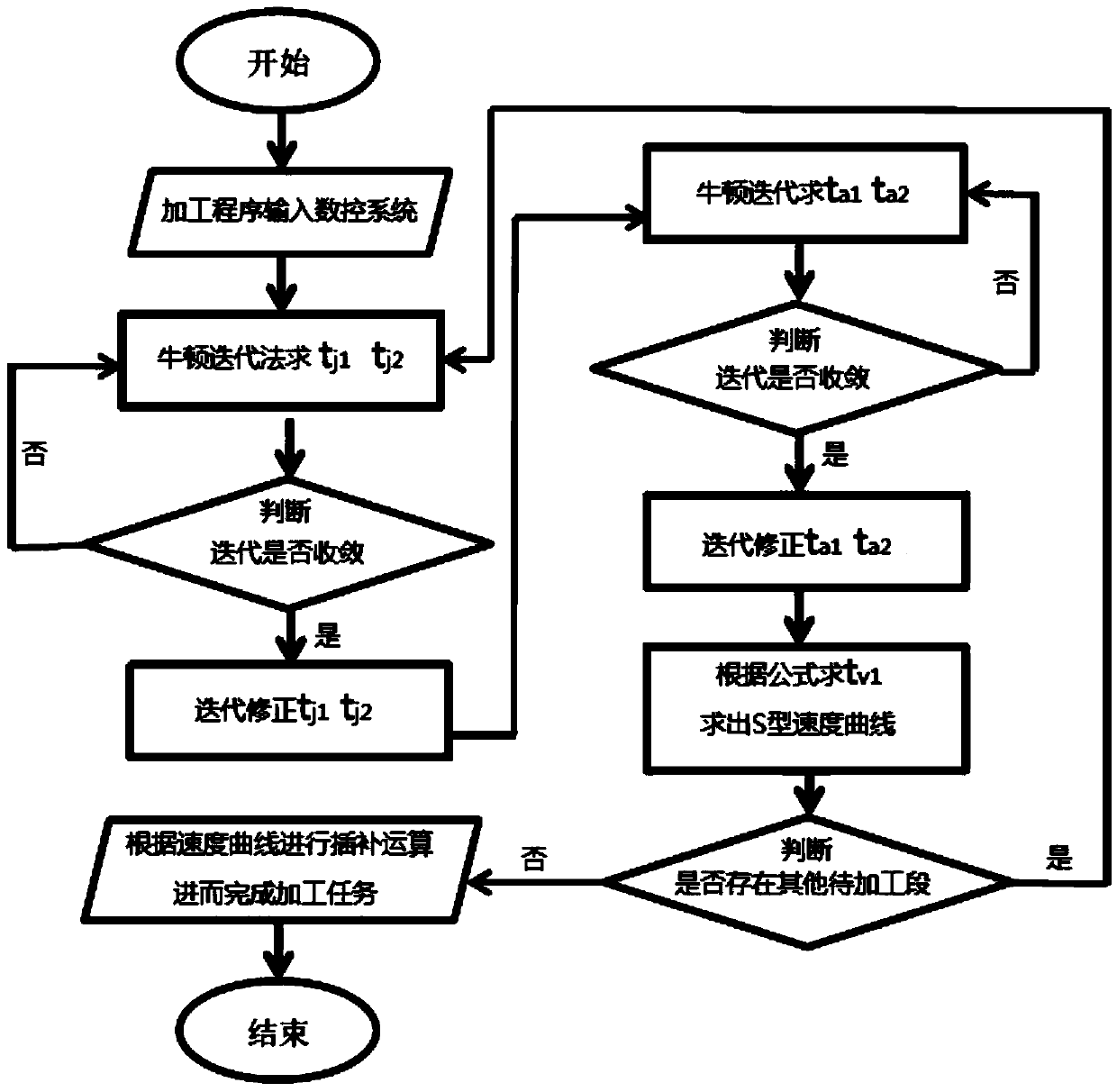

[0108] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0109] like figure 1 , 2, 3, 4 The embodiment shows that the S-type acceleration and deceleration control method of the CNC machine tool includes the following steps:

[0110] Step 1: Input the CNC machine tool processing program into the CNC system to obtain data such as the coordinate values of the start and end points of each line segment trajectory, and then calculate the length of each line segment trajectory, and determine the jerk and maximum limit acceleration according to the process requirements of the CNC system and the workpiece , the maximum speed limit.

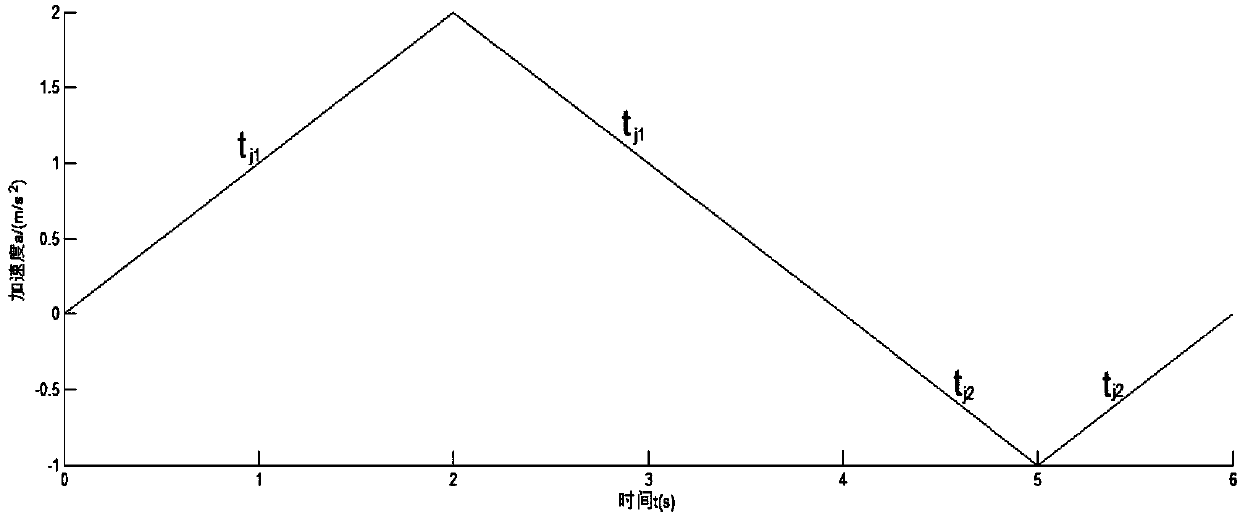

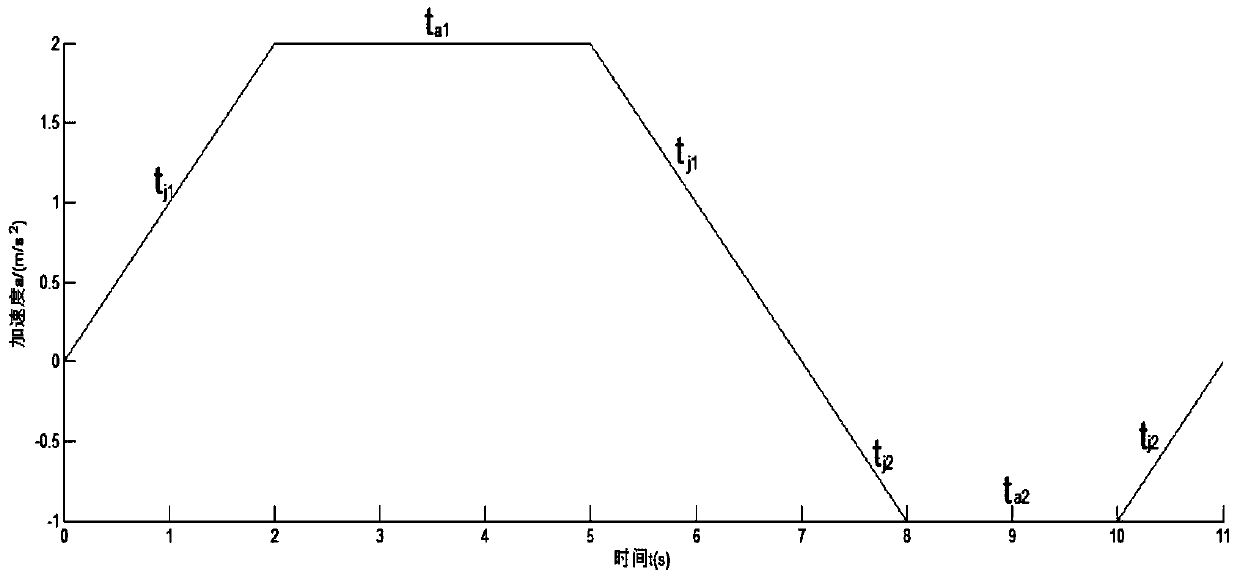

[0111] Step 2: Find the acceleration change time of the first segment of the track to be processed, that is, t j1 , t j2 value.

[0112] In general, S-type acceleration and deceleration control includes seven acceleration change sections, namely jerk section, uniform acceleration se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com