Numerical controller having function to switch between pressure control and position control

A numerical control device, pressure control technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of discontinuity, mold buffering mechanical impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

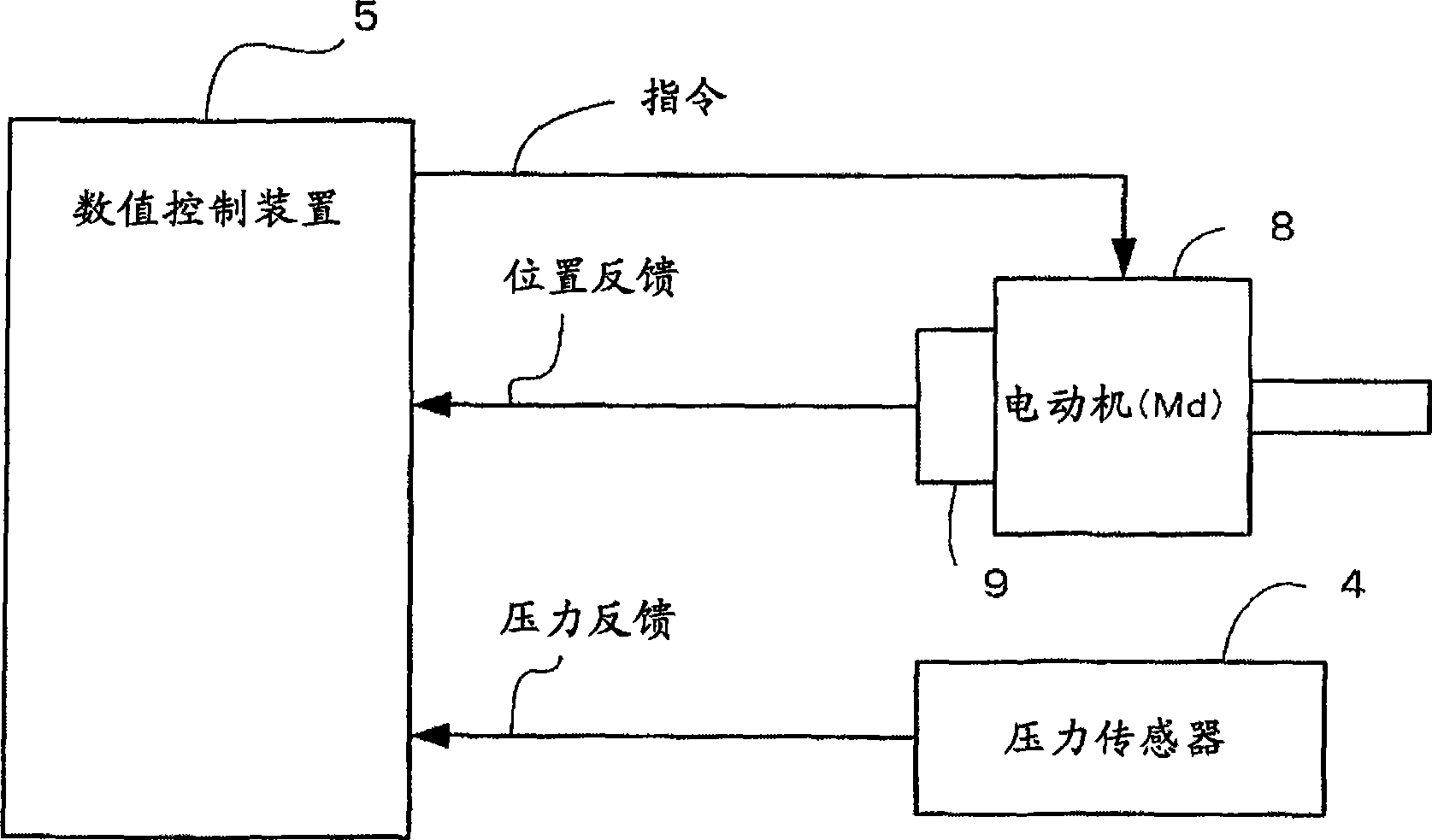

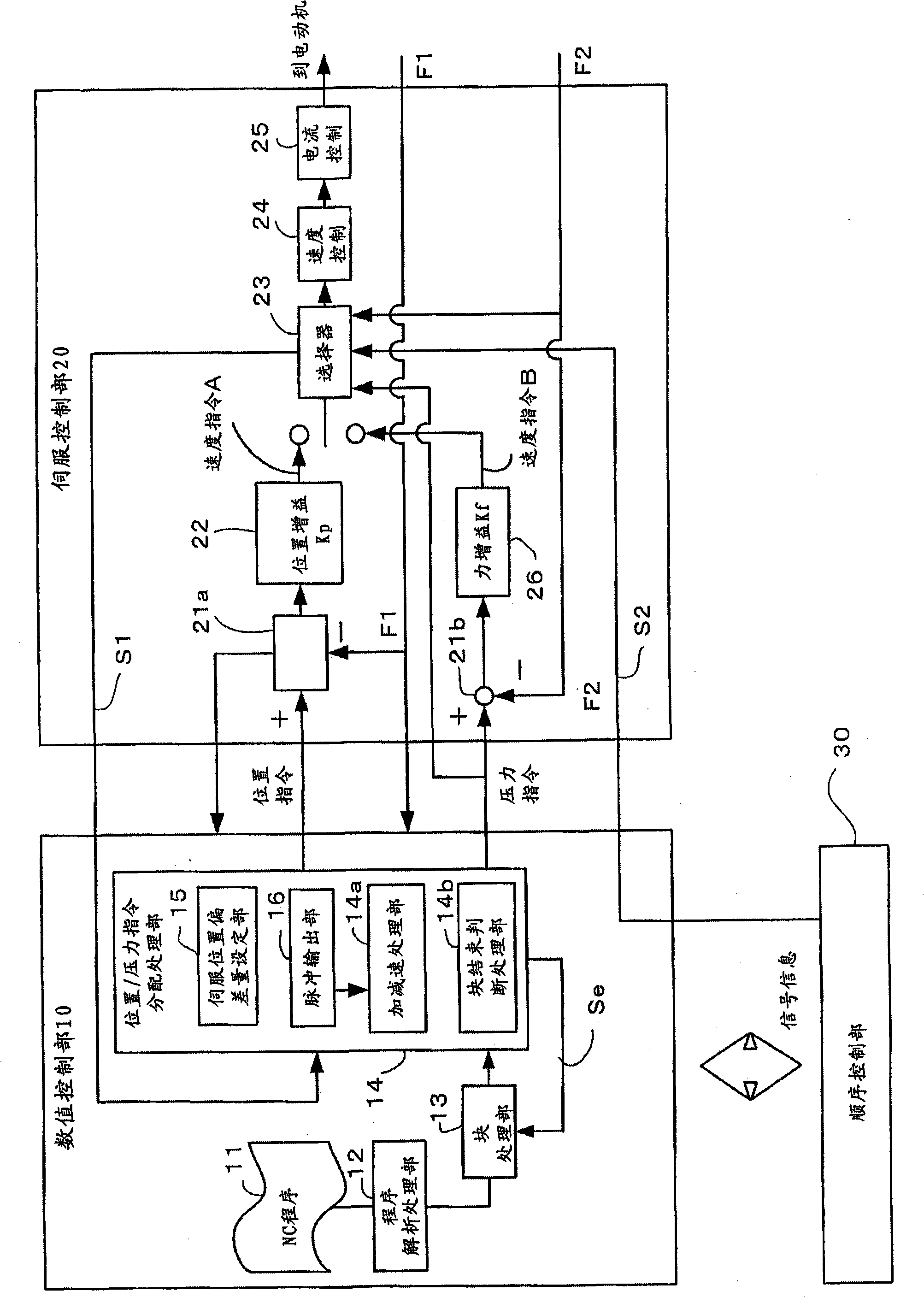

[0025] figure 1 A numerical controller 5 for performing pressure control is shown. The numerical controller 5 obtains the pressure feedback value from the pressure sensor 4 mounted on the control object and the position feedback value from the position detector 9 that detects the rotational position of the mold cushion servo motor 8 that drives the control object, and based on these feedbacks, The value drive controls the servo motor 8 . Here, the numerical control device 5 is as referring to image 3 As will be described later, it is composed of a numerical control (NC) unit 10 and a servo control unit 20 .

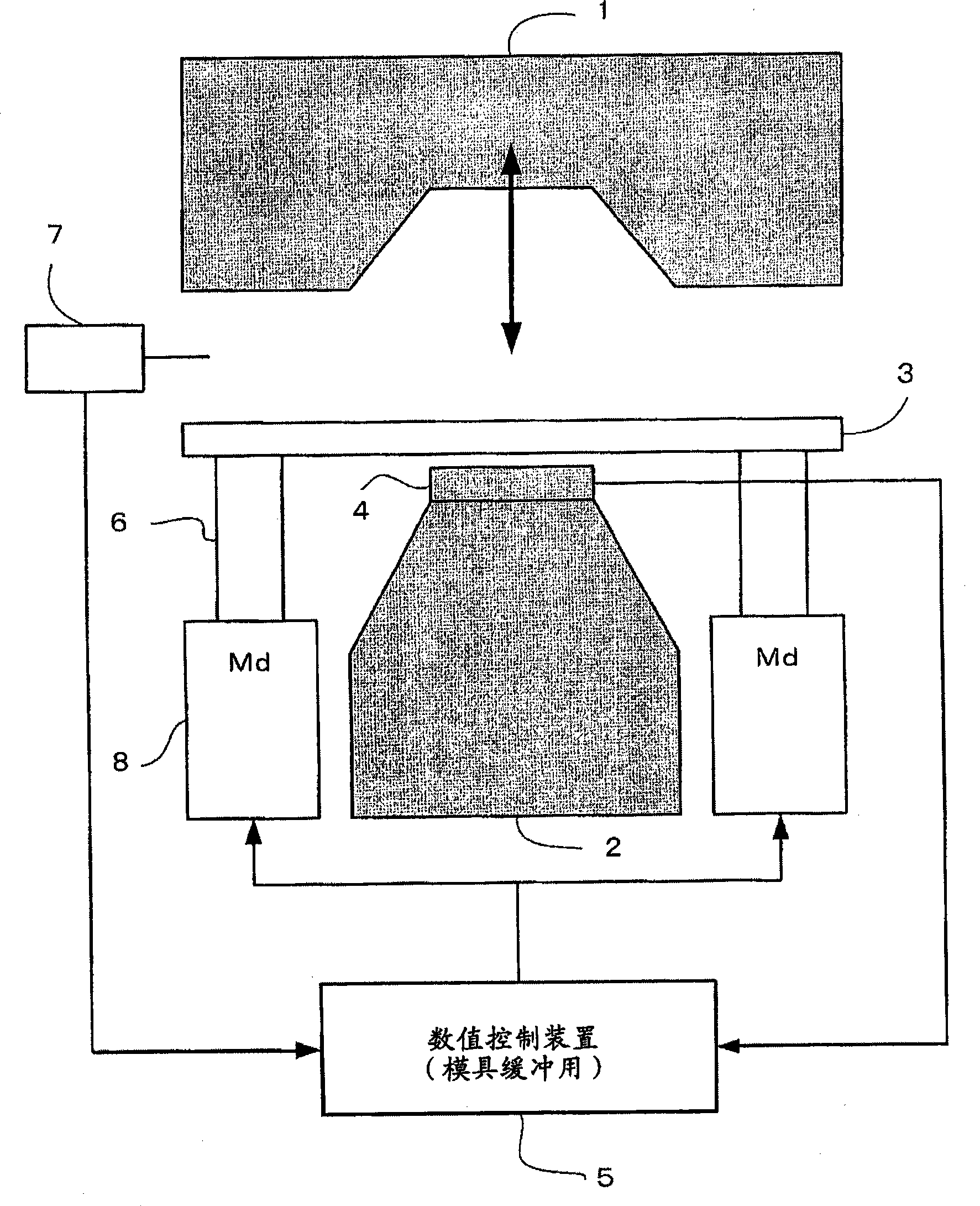

[0026] figure 2 It is a figure explaining control of the die cushion device in a press machine using one embodiment of the numerical control device 5 of this invention. The numerical controller 5 such as figure 2 As shown, the drive control of the die cushioning servo motor 8 for driving the die cushioning member 6 of the die cushioning device is performed.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com