Welding system and consumable electrode welding method

A welding system and welding method technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of welding torch acceleration and deceleration reduction, long invalid time, etc., to achieve the effect of reducing invalid time and reducing production takt time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

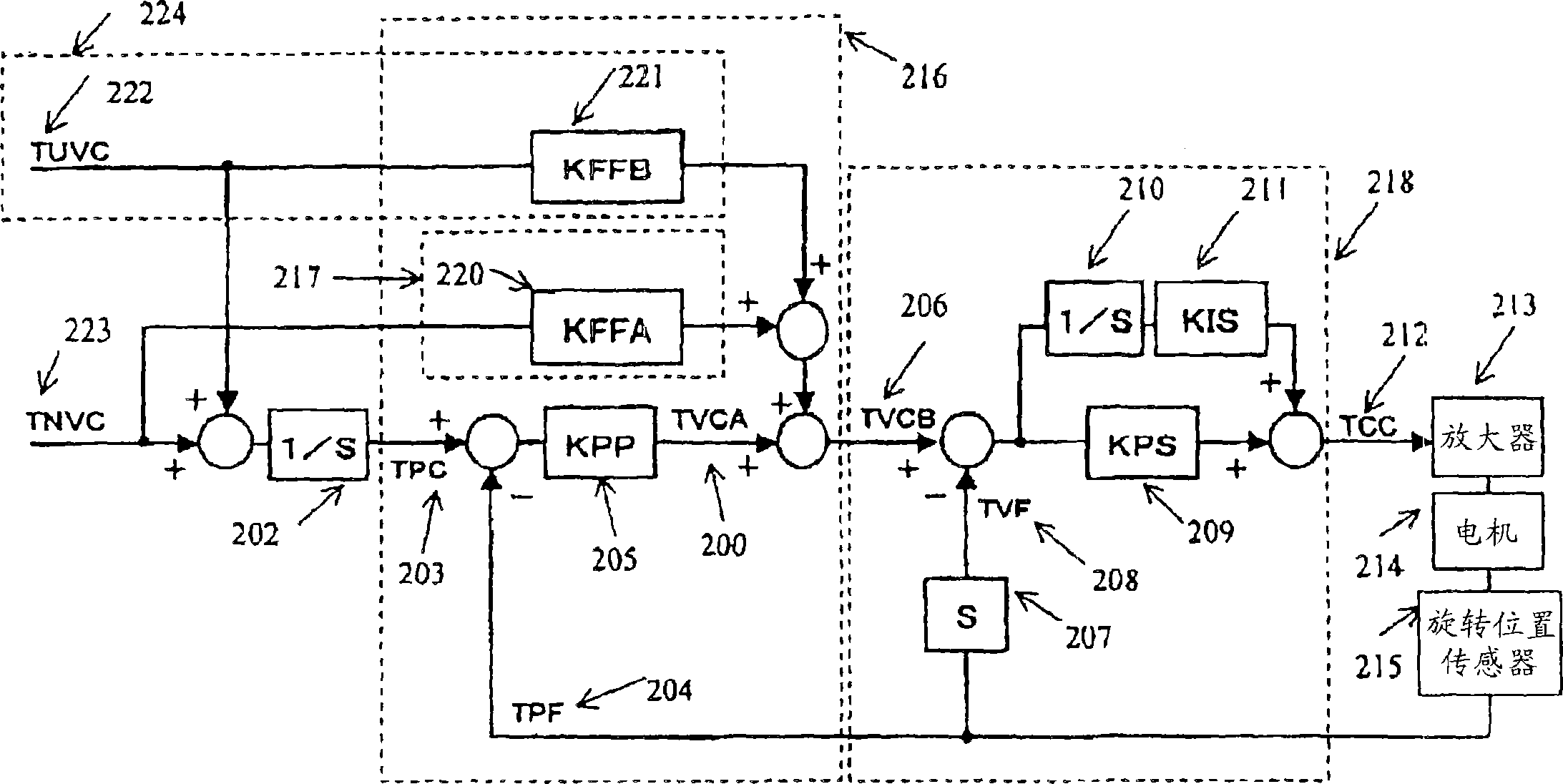

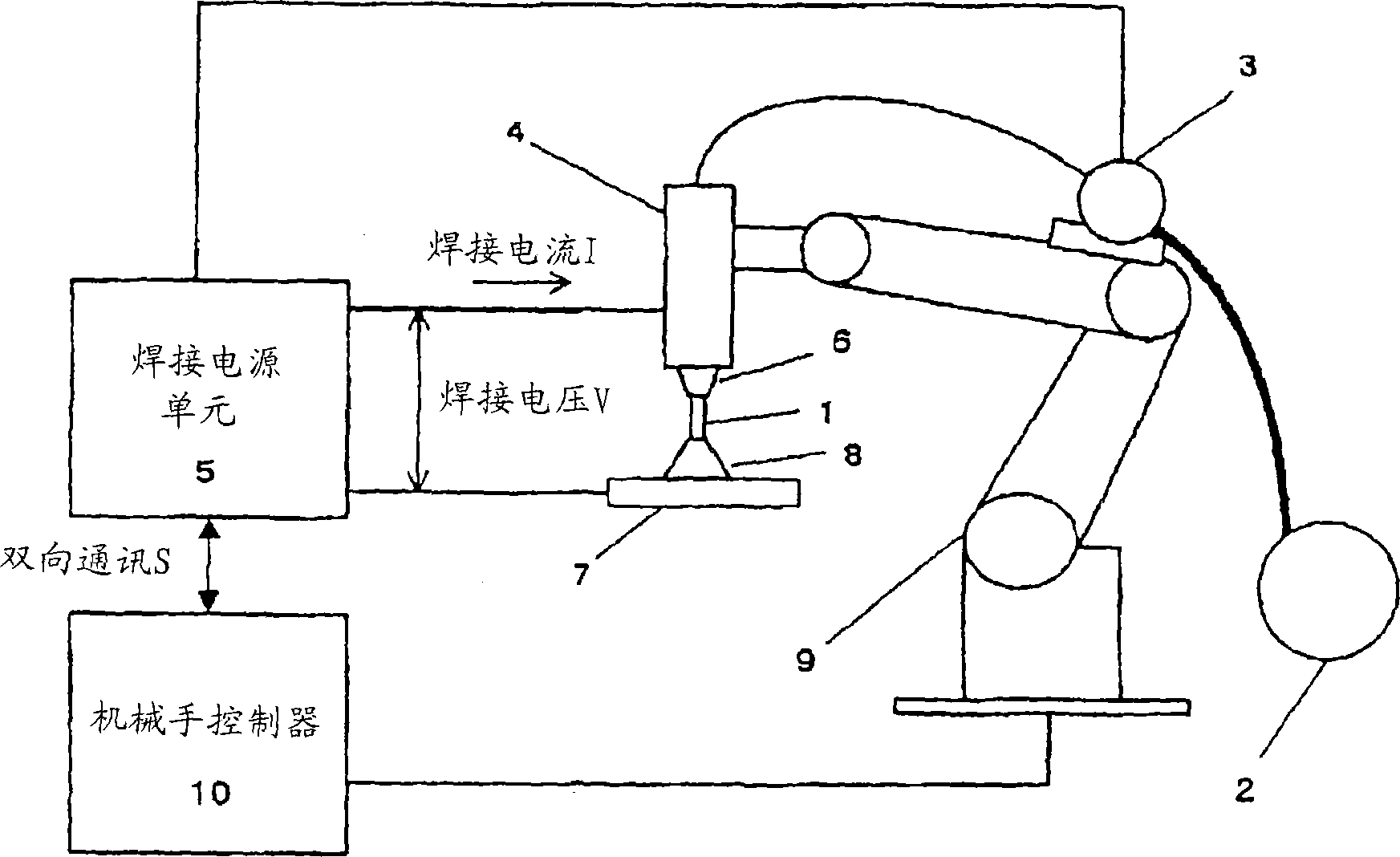

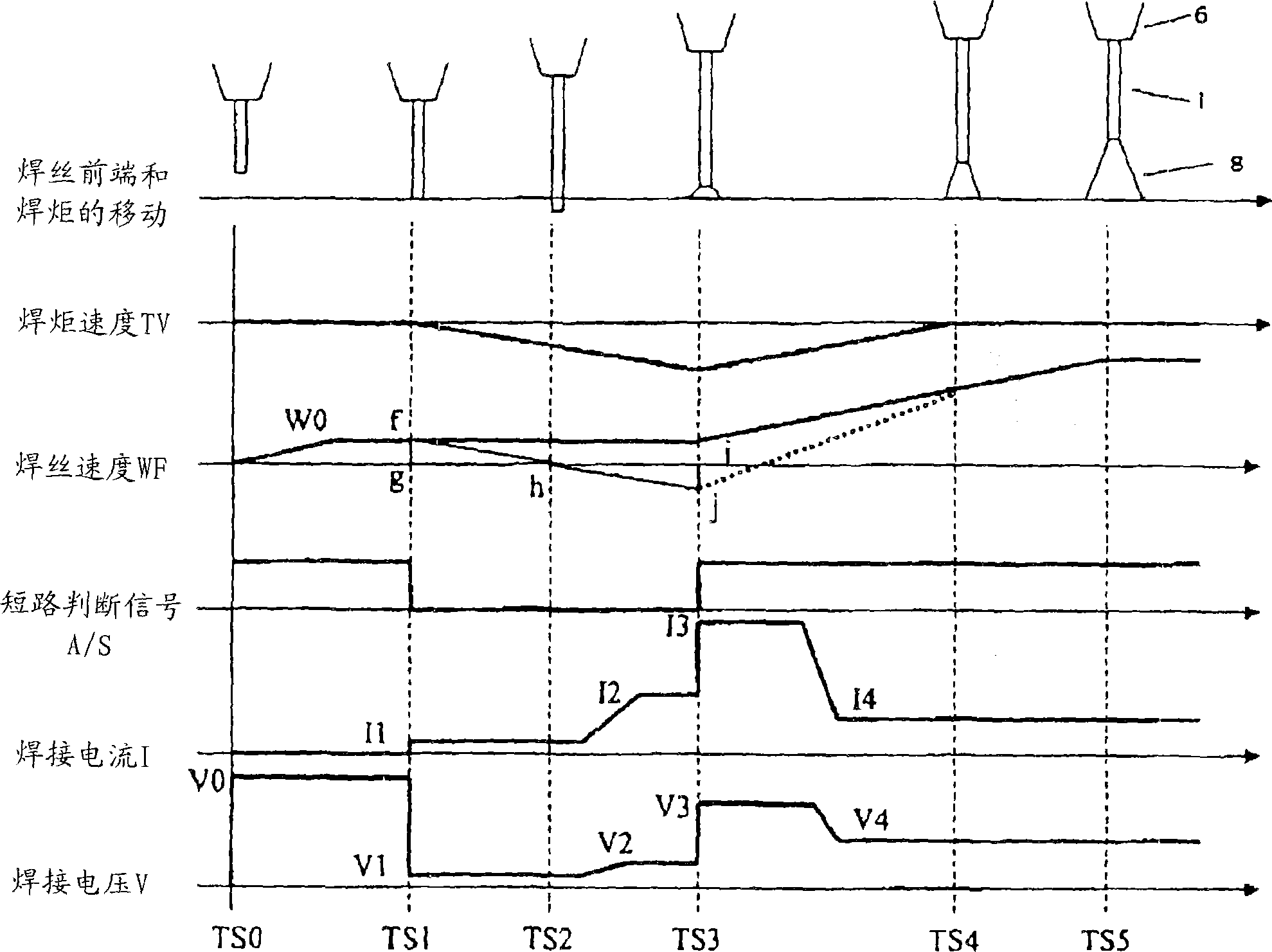

[0113] The following will refer to Figures 1 to 3 and Figures 7 and 8 describe an embodiment of the present invention.

[0114] refer to figure 2 and 3 , the configuration and arc starting process of the welding system in this embodiment will be described. Next refer to figure 1 , 7 and 8, the position control loop of the manipulator controller 10 in this embodiment will be described.

[0115] figure 2 is a schematic configuration diagram showing the welding system in this embodiment. The welding wire 1 serving as a consumable electrode is supplied from a winding reel 2 in the direction of the welding torch 4 by means of a wire feed motor 3 .

[0116] The welding power supply unit 5 applies a preset welding current I and welding voltage V between the welding wire 1 and the base material 7 used as a workpiece through the welding torch 4 and the welding chip 6, thereby generating an arc 8, and controls the welding wire feeding motor 3 to perform welding .

[0117] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com