Heave compensating control system of ocean exploration equipment and control method

A technology of heave compensation and control system, applied in the direction of spring mechanism, hoisting device, etc., can solve the problems of large amount of information and processed information, large lag of heave compensation system, large power consumption, etc. The effect of less data processing, fast control speed and energy saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

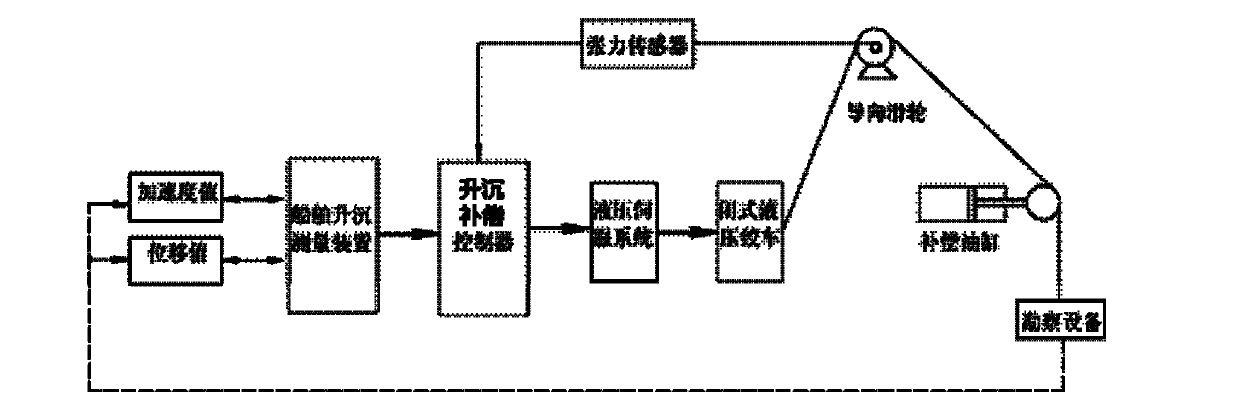

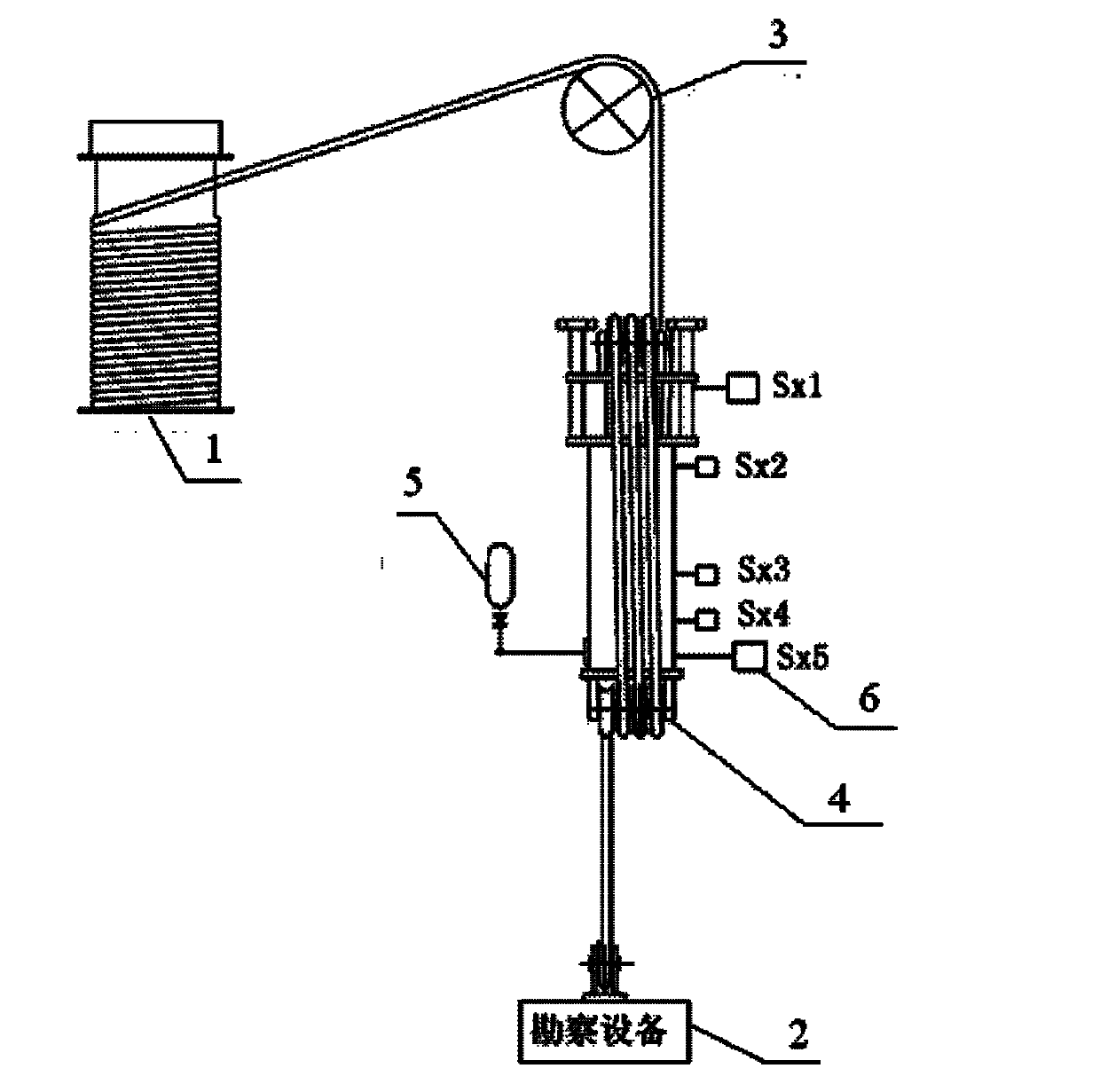

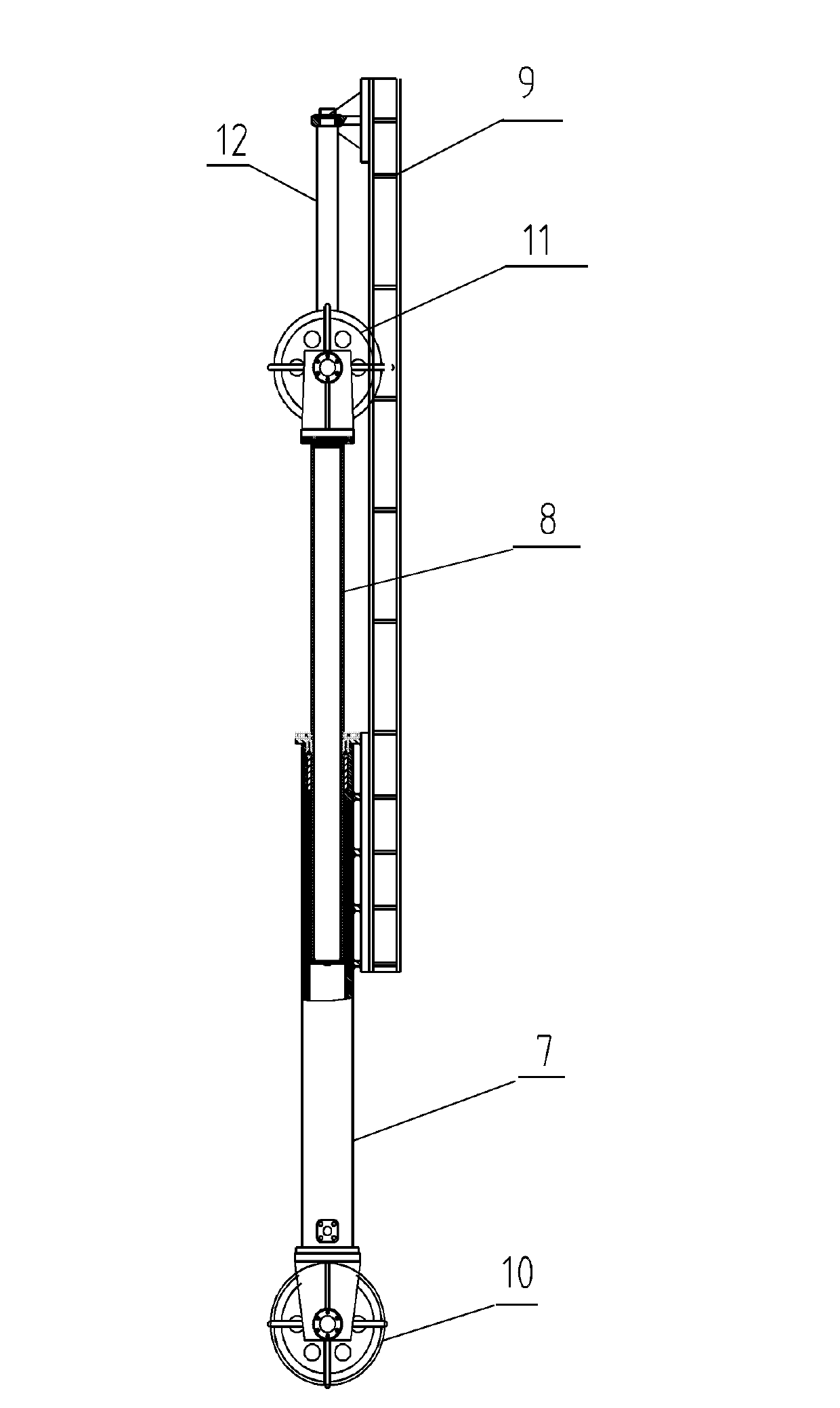

[0026] as attached figure 1 And attached figure 2 As shown, the compensation control system of the present invention mainly includes a ship heave measurement device, a tension sensor, a heave compensation controller, a compensation cylinder 4, a position switch for cylinder stroke monitoring, and a guide pulley 3.

[0027] The ship heave measurement device is used to collect the acceleration value and displacement value in the vertical direction of the ship, and calculate the passive compensation pressure.

[0028] The tension sensor of the present invention is installed on the central axis of the guide pulley 3 on the derrick, the tension sensor is used to measure the tension parameter of the steel wire rope of the hydraulic winch, and the heave compensation controller module calculates the compensation amount according to the tension parameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com