Device for utilizing front edge rudder pieces to adjust output power of rotating blade and method thereof

A technology of output power and rotating blades, which is applied in the control of wind turbines, wind turbine components, wind turbines, etc., can solve the problems of reduced power generation efficiency of wind turbines, aggravated aeroelastic deformation of blades, and decreased aerodynamic performance of blades, so as to improve operation Efficiency, improved aerodynamic performance, fast control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the purpose of the disclosed embodiments is to help further understand the present invention, but those skilled in the art can understand that various replacements and modifications are possible without departing from the spirit and scope of the present invention and the appended claims of. Therefore, the present invention should not be limited to the content disclosed in the embodiments, and the protection scope of the present invention is subject to the scope defined in the claims.

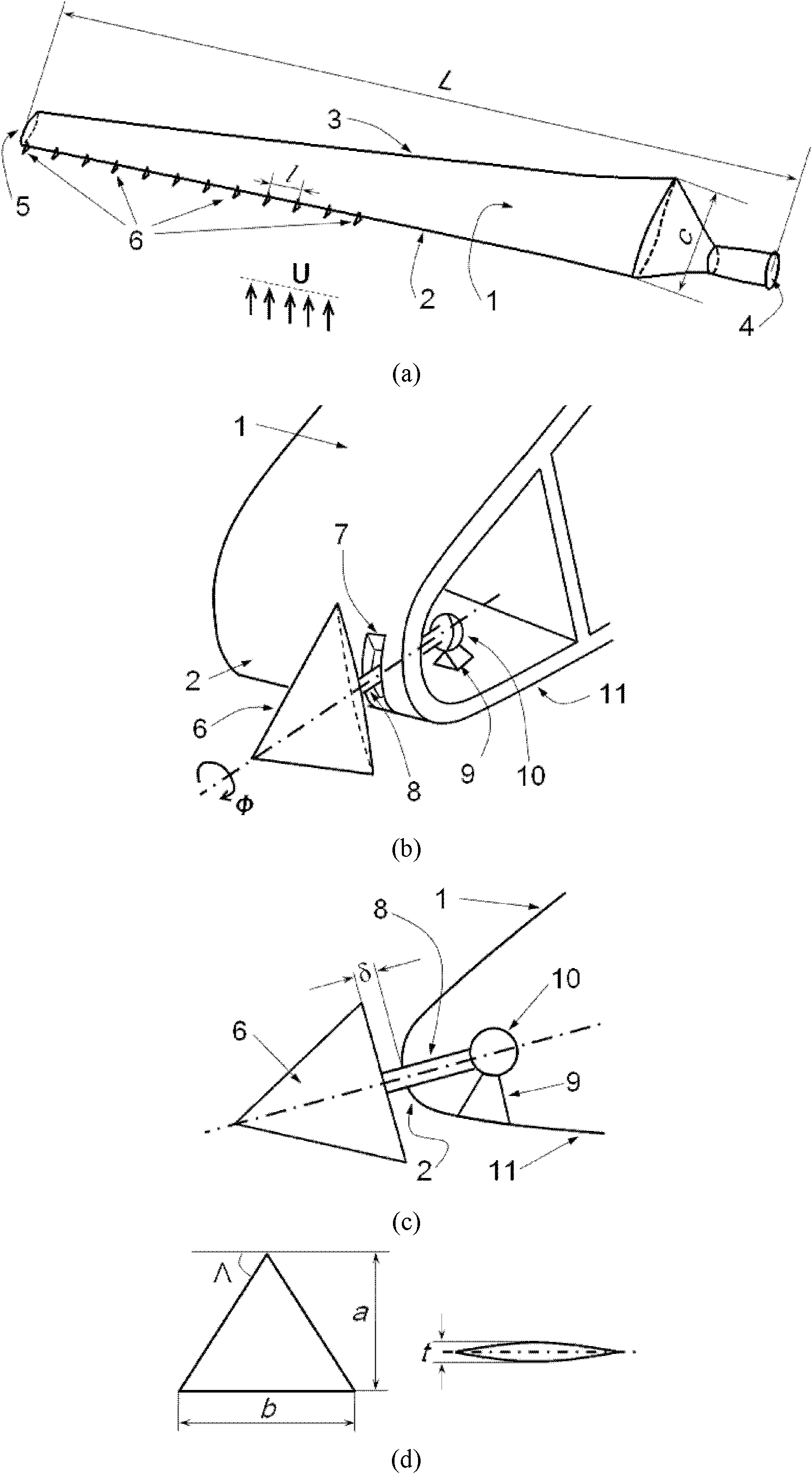

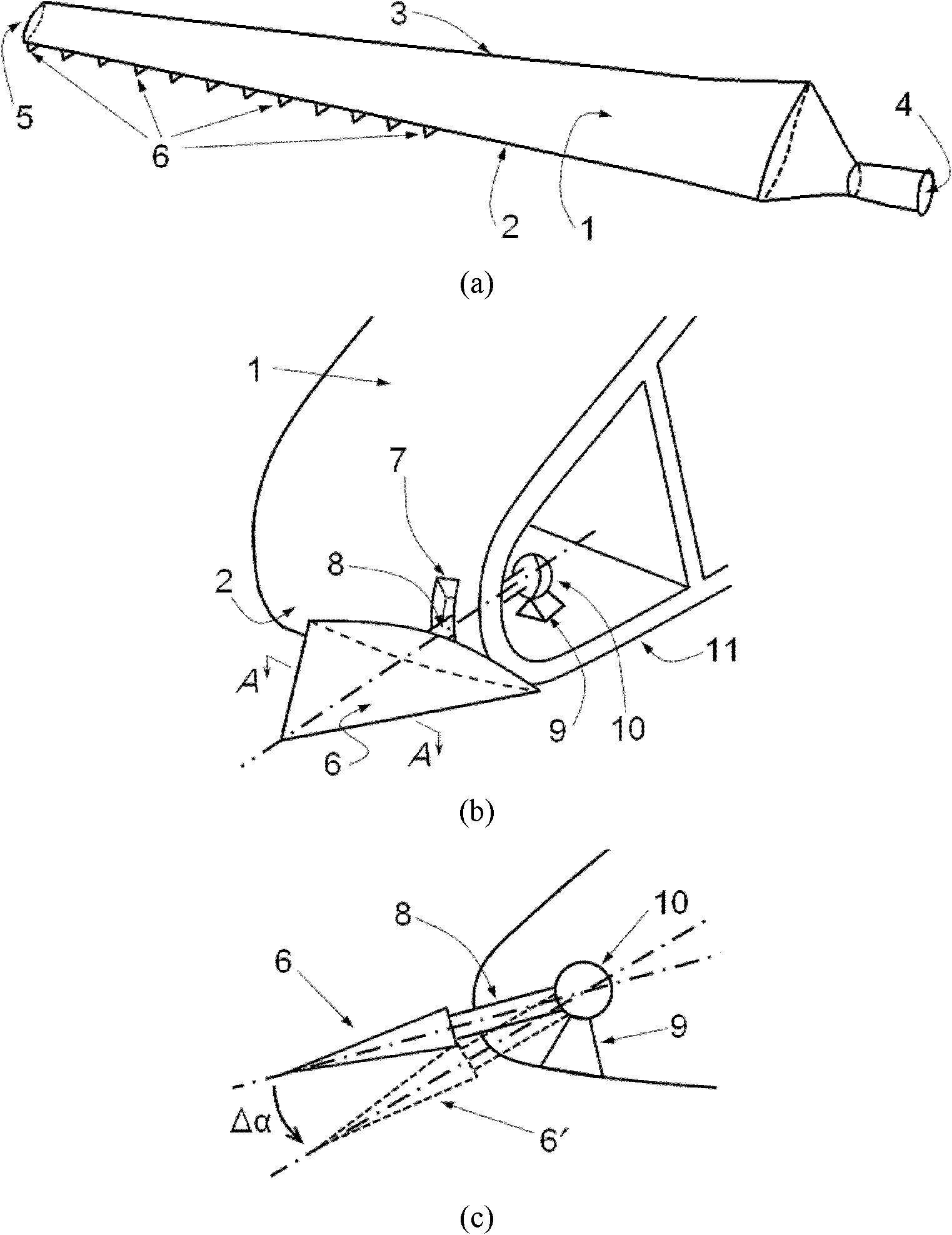

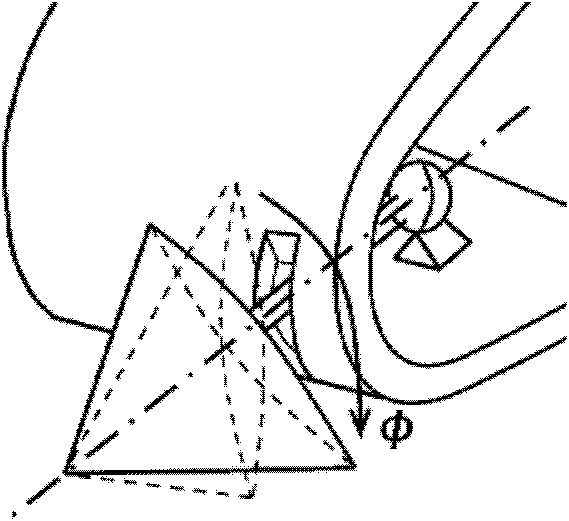

[0050] The overall structure of the implementation case of this patent is as follows: figure 1 with figure 2 shown.

[0051] figure 1 It is a structural schematic diagram of the rotating blade of the wind power generator and the control rudder blade designed by this patent. figure 1 In (a): structure 1 represents the upper surface (suction surface) of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com