Apparatus for automatically regulating tension of conductor

An automatic adjustment device and self-adjustment technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as troublesome adjustment, difficult accuracy, and long adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

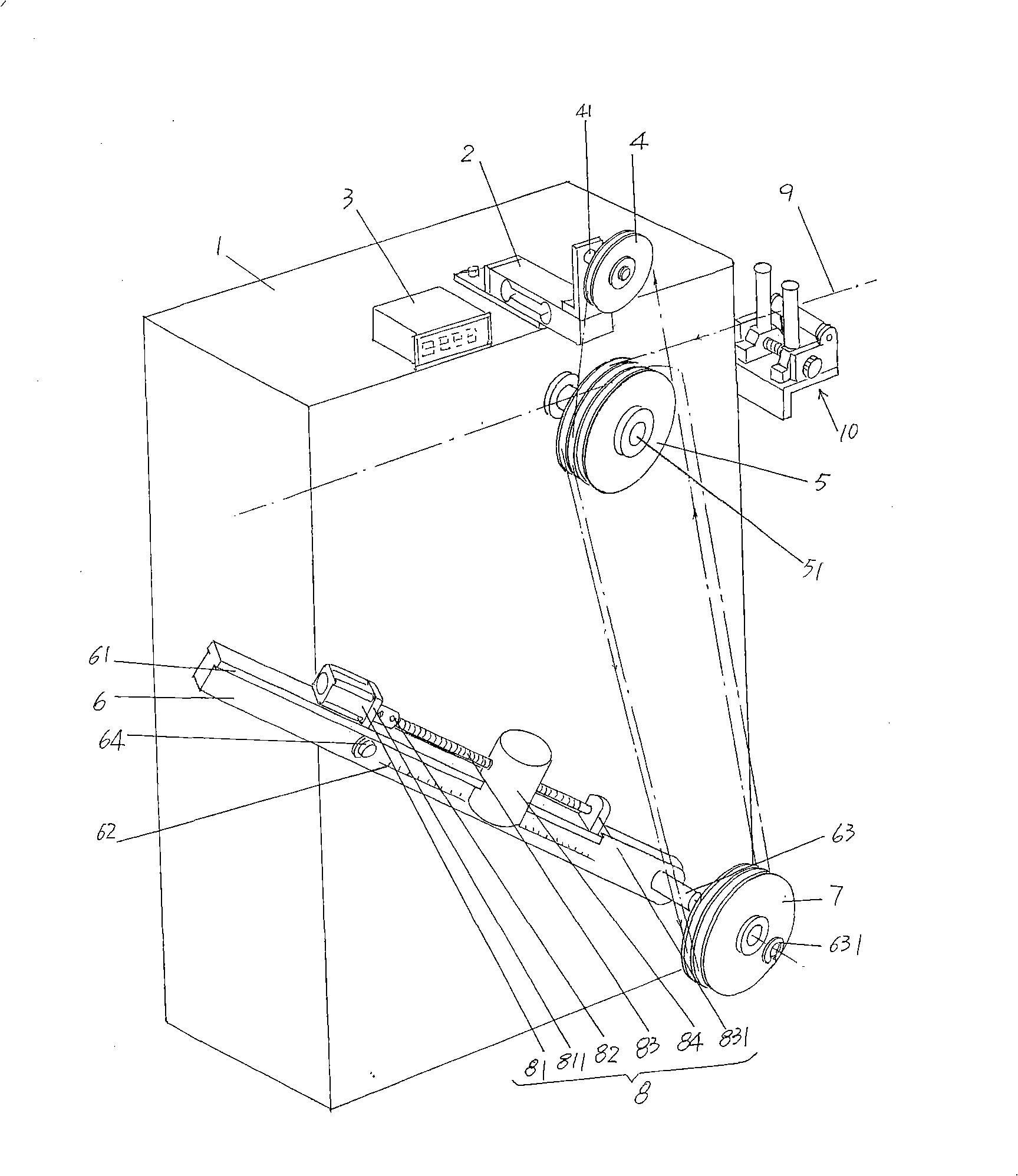

[0010] Please see accompanying drawing, provided the frame 1 of tension machine, this frame 1 also can be referred to as the shell of tension machine, same as prior art, tension sensor 2 and tension sensor 2 and tension sensor 2 are installed on the top of frame 1 The display 3, the tension sensor 2 and the tension display 3 are both electrically connected, and are electrically connected with the controller of the tension machine. The tension wheel 4 is set on the tension sensor 2 through the tension wheel shaft 41 , and the guide wheel 5 is set on one side of the frame 1 through the guide wheel shaft 51 . The fork 6 is hingedly connected to the side of the frame 1 by the fork hinge shaft 64, the upper surface of the fork 6 is processed with a guide rail 61, and the near middle part of the outward side of the fork 6 is provided with a There is a tension scale line 62, a swing wheel shaft 63 is extended at the front end of the swing rod 6, that is, the right end of the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com