Bow net electric contact characteristic testing device

A characteristic test and electrical contact technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

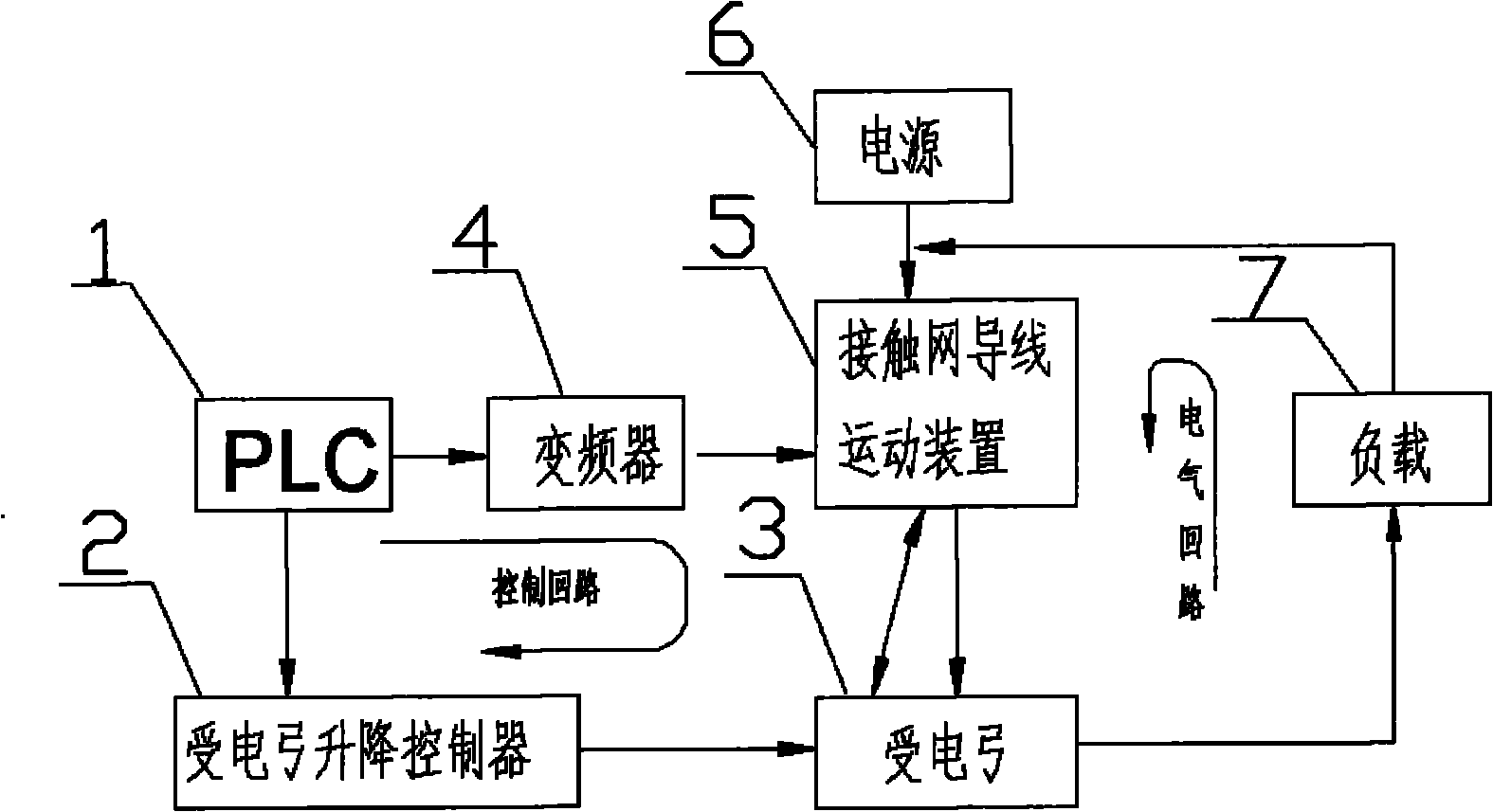

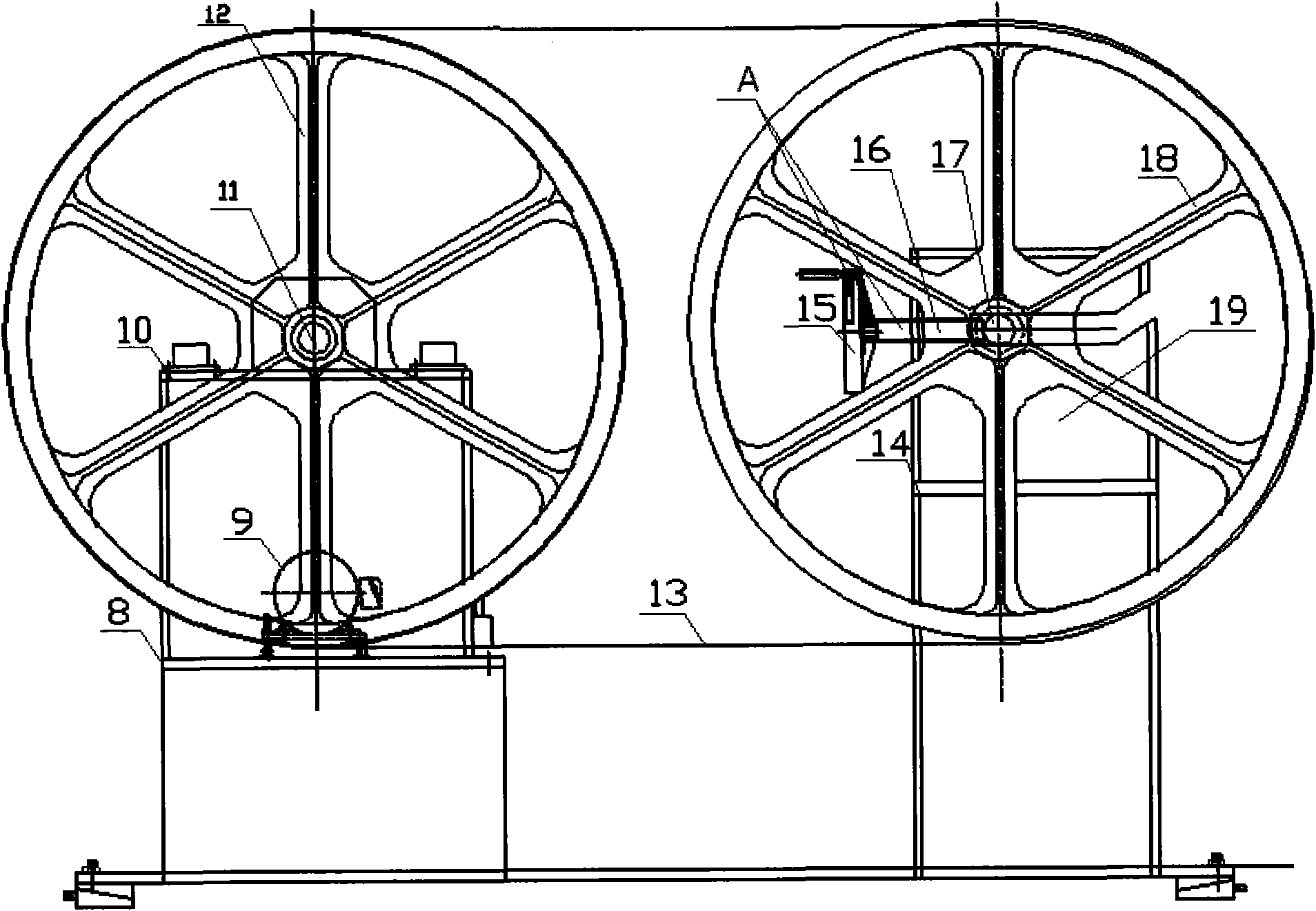

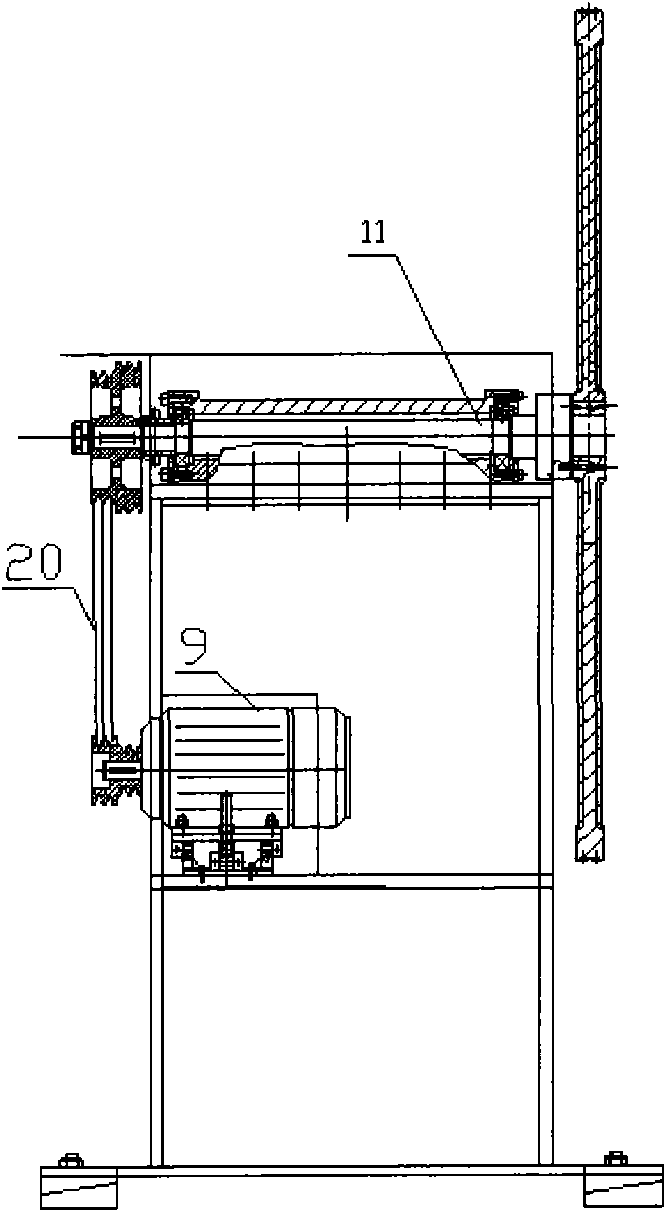

[0015] Pantograph-catenary electrical contact characteristic test device of the present invention see Figure 1-3 As shown, it includes a power supply 6 (the model can be RAC300), a load 7 (the load can use resistance, inductance, or a series or parallel connection of resistance and inductance, and it can work normally at a rated current of 300A), a motor 9, and A motor control system composed of a programmable logic controller (PLC) 1 and a frequency converter 4 and a power transmission system composed of a transmission belt 20, a driving wheel center shaft 11, a driving wheel 12, a driven wheel 18, catenary wires 13, and a pantograph 3 , pantograph lifting controller 2 and catenary wire tension regulator A (regulator A is composed of adjusting screw rod 16 and adjusting handle 15 installed on the driven wheel bracket), RAC300 power supply 6 passes through driving wheel center shaft 11, driving The wheel 12 and the catenary wire 13 are connected with the pantograph 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com