Electric stringing and tightening device

A wire tightening and wire-strapping technology, used in overhead lines/cable equipment, adjusting/maintaining mechanical tension, etc., can solve the problems of many times of wire tightening, time-consuming and labor-intensive, etc., and achieve the effect of saving man-hours, improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

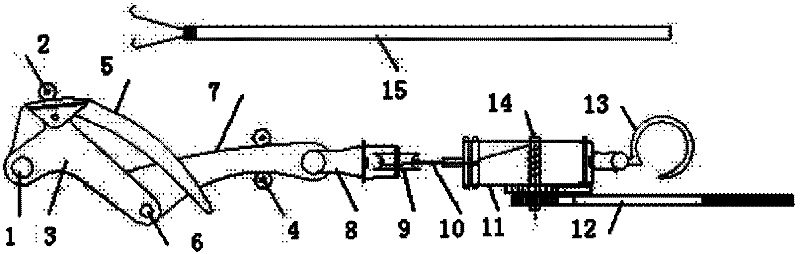

[0014] Specific embodiments of the present invention, such as figure 1 As shown, a kind of electric wire tensioning device comprises the front tensioning arm 3 and the rear tensioning arm 7 which are hinged by the hinge shaft 6, and the front end of the front tensioning arm 3 and the rear end of the rear tensioning arm 7 are hinged respectively. Wire rocker 5 and pulley seat 8 and its pulley 9 and tightening rope 10, and the tightening mechanism connected with tightening rope 10, the tightening mechanism is composed of tightening rope 10, the main body 11 of the tightener, the handle 12 of the tightener, Tightening hook 13, tight bobbin 14 is formed, it is characterized in that:

[0015] A. Set the clamping nut 2 on the front upper part of the front tensioning arm 3;

[0016] B. Set pay-off nuts 4 respectively at the upper and lower positions behind the rear tightening arm 7;

[0017] C. At the position of the upper and lower pay-off nuts 4, there is a pay-off rod 15 with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com