Ceramic filter with double-blind-groove capacitive coupling structure

A ceramic filter and capacitive coupling technology, which is applied in the field of communication, can solve the problems of difficult capacitive coupling debugging, difficult production and preparation, and poor adjustment accuracy, and achieve the effects of flexible and adjustable blind slot length, simple structure, and convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

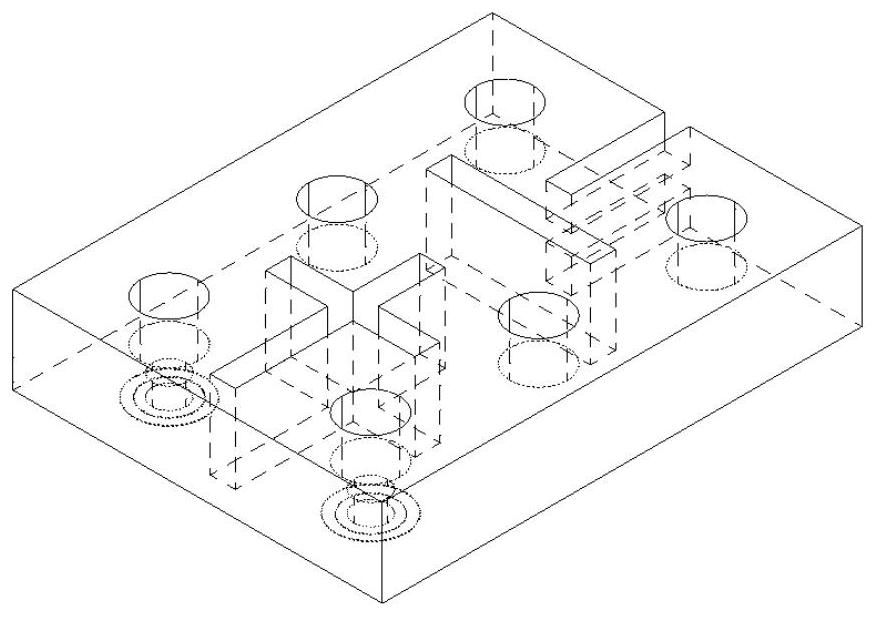

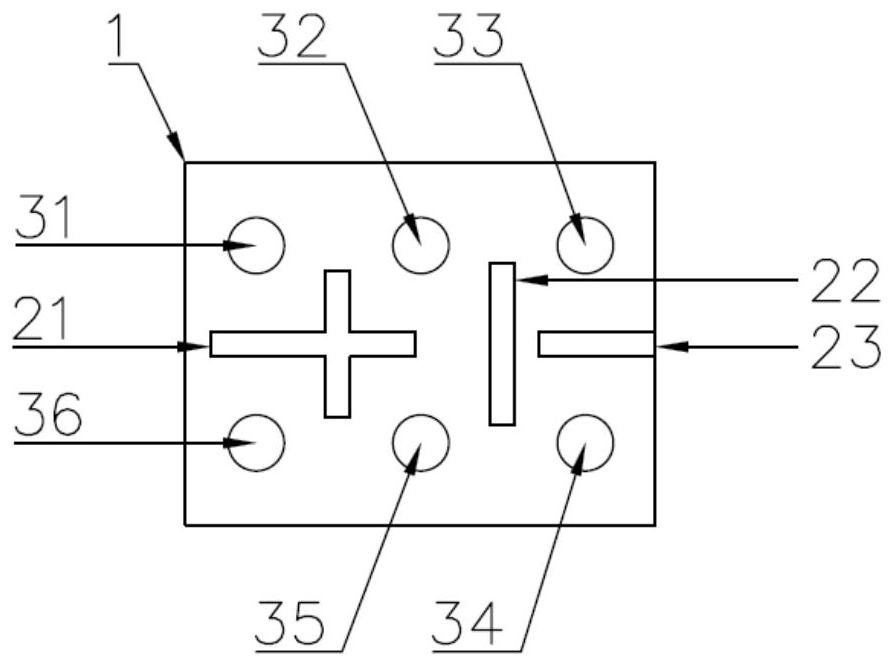

[0026] Such as Figure 1 to Figure 4 As shown, one embodiment of the present invention provides a ceramic filter, including a ceramic filter body 1 with a metal coating on the surface, a tuning hole on the upper surface of the body, a coupling slot and a capacitive coupling structure of double blind slots. There are 6 tuning holes on the upper surface of the ceramic filter body. The tuning holes are blind holes. The tuning holes and part of the body independently form a resonator. The resonant frequency of the resonator can be adjusted by adjusting the depth of the blind holes. The ceramic filter body 1 is provided with a through coupling slot, the coupling slot is a rectangular slot with a set length, width and height, the rectangular slot is located between the tuning holes, and the coupling slots between the tuning holes 31, 32, 35, 36 are connected to form a The cross-shaped structure 21 and the coupling grooves between the tuning holes 32, 33, 34, 35 are connected to form...

Embodiment 2

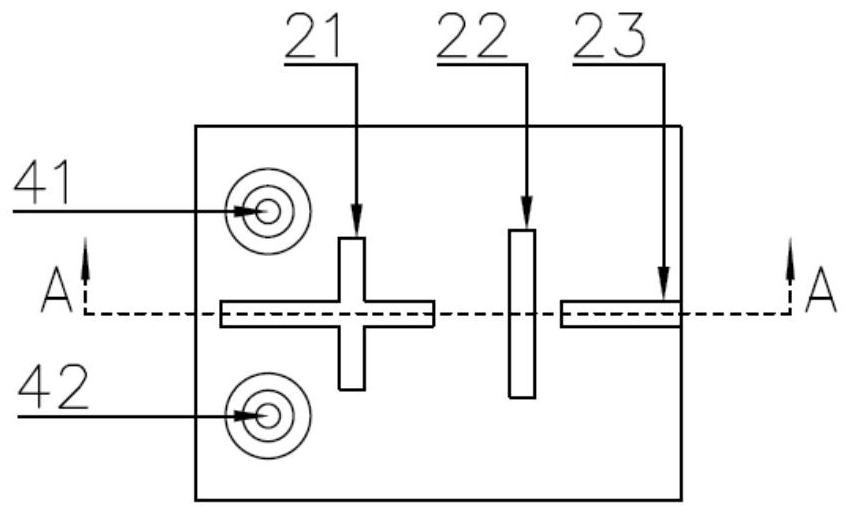

[0031] Such as Figure 5 to Figure 8 As shown, in another embodiment of the present invention, on the basis of the foregoing content, the capacitive coupling structure 23 is moved from the right end to the left, and is connected with the inline coupling groove 22. The frequency response curve of the filter is as follows Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com