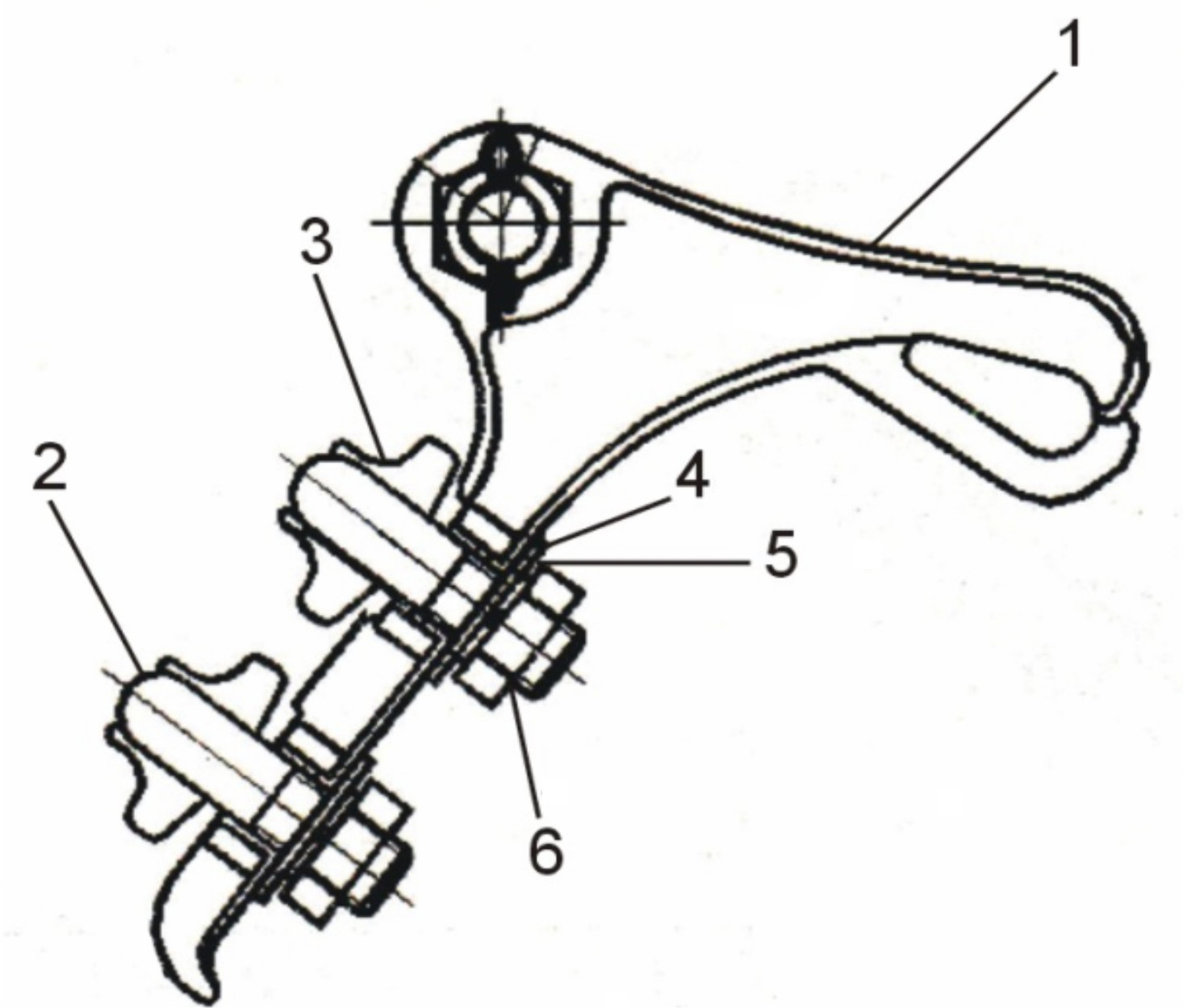

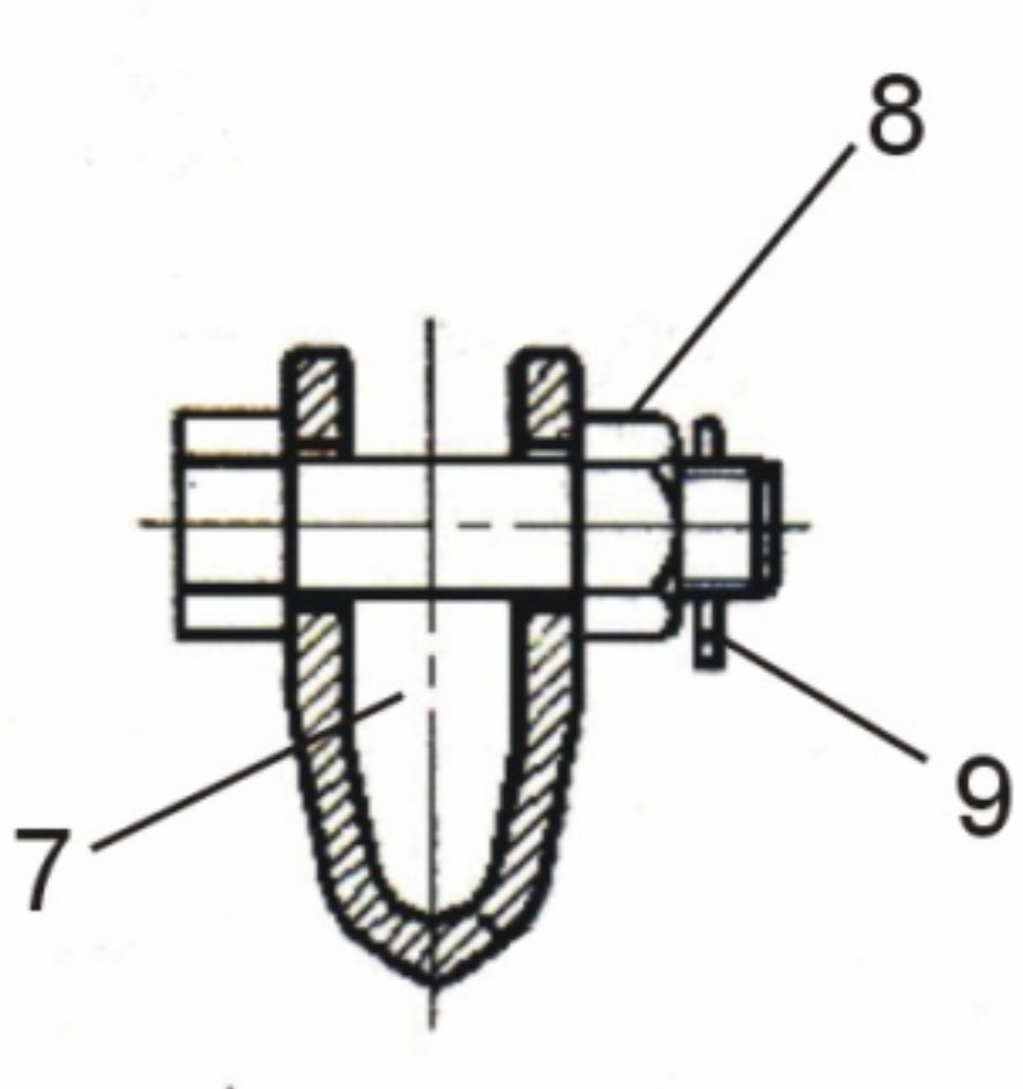

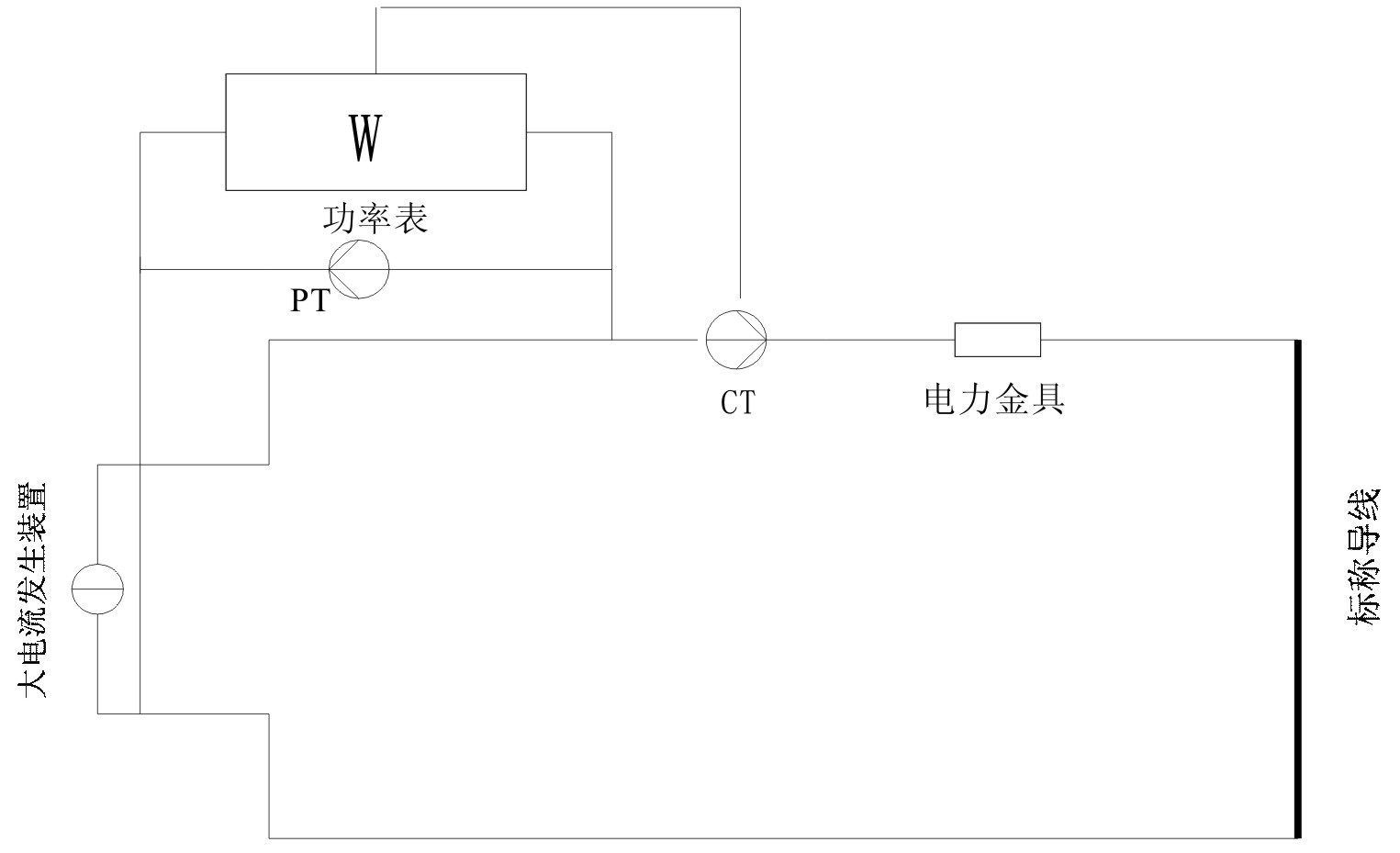

Energy-saving bolt-type strain clamp

A tension-resistant clamp and bolt-type technology, which is applied in the direction of adjusting/maintaining mechanical tension, can solve the problems of eddy current loss, high relative magnetic permeability of ferromagnetic metal fittings, and large eddy current loss, so as to reduce corona loss and make molds The effect of high yield and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: The content of the austenitic steel by weight percentage: manganese: 23%, aluminum 3.8%, chromium 2.5%, vanadium 2.3%, carbon 0.15%, lanthanum-cerium complex rare earth 0.24%, silicon 0.6%, sulfur < 0.035%, nitrogen<0.026%, phosphorus<0.033%.

Embodiment 2

[0057] Embodiment 2: The content of the austenitic steel by weight percentage: manganese: 23%, aluminum 4.0%, chromium 2.5%, vanadium 2.3%, carbon 0.15%, lanthanum-cerium complex rare earth 0.25%, silicon 0.6%, sulfur < 0.035%, nitrogen<0.026%, phosphorus<0.033%.

Embodiment 3

[0058] Embodiment 3: The content of the austenitic steel by weight percentage: manganese: 23%, aluminum 4%, chromium 2.5%, vanadium 2.5%, carbon 0.15%, lanthanum-cerium complex rare earth 0.25%, silicon 0.6%, sulfur < 0.03%, nitrogen<0.02%, phosphorus<0.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com