Tension balancer for overhead line

An overhead line and balancer technology, which is used in overhead lines, overhead line/cable equipment, adjusting/maintaining mechanical tension, etc., can solve problems such as tension balance damage, bearing damage, poor dust performance, etc., to achieve good durability, Avoid the effects of tension imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

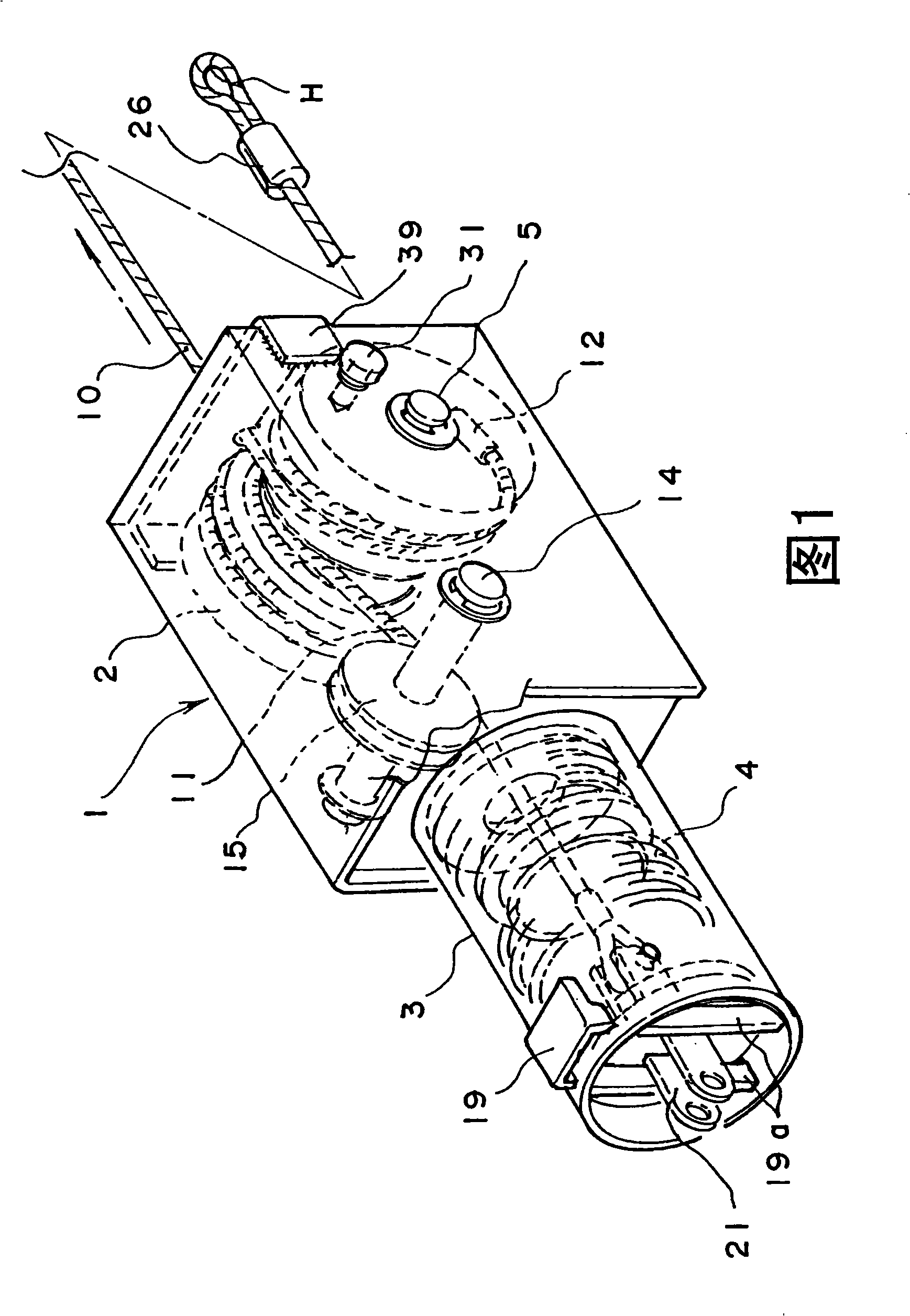

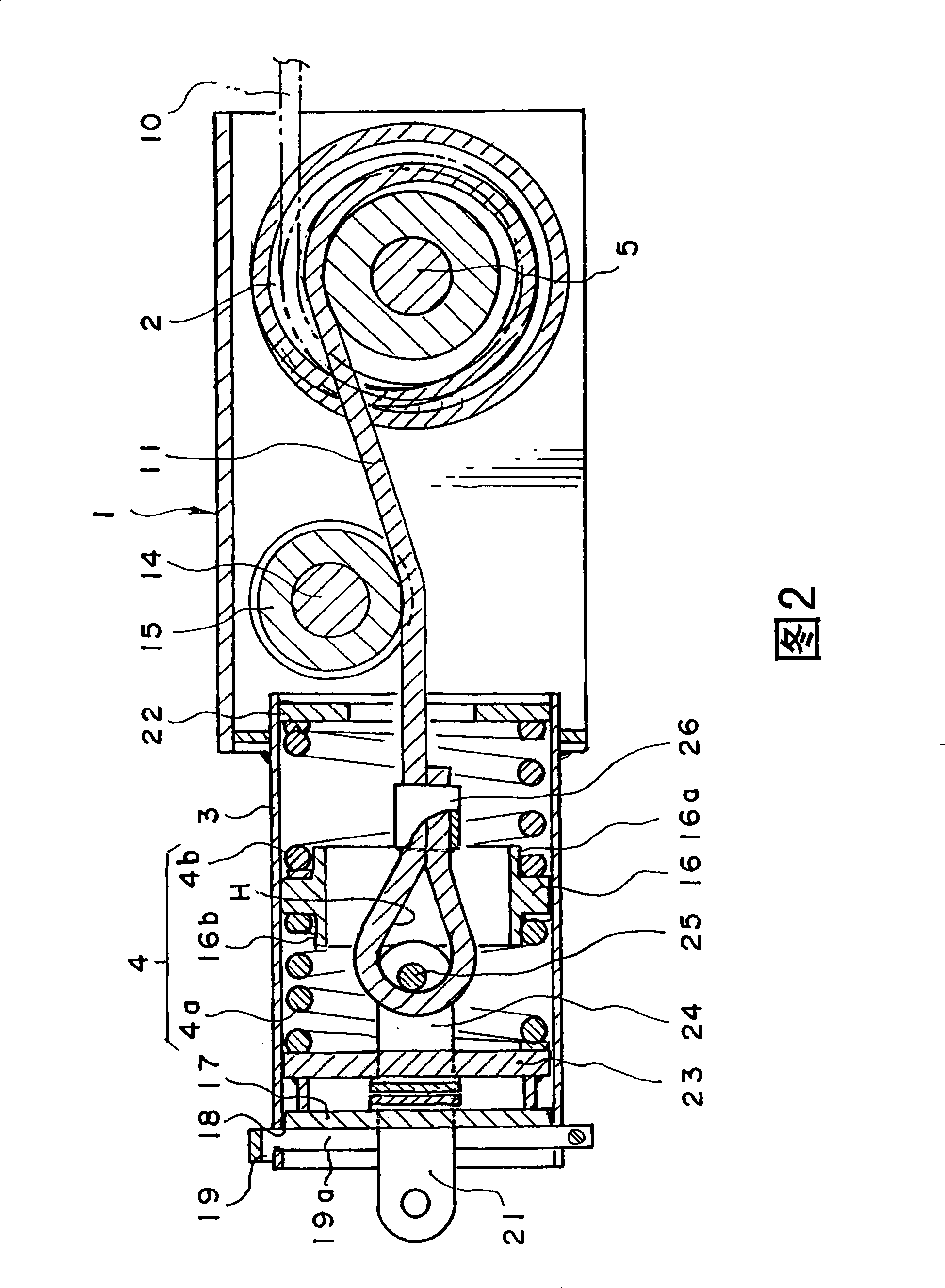

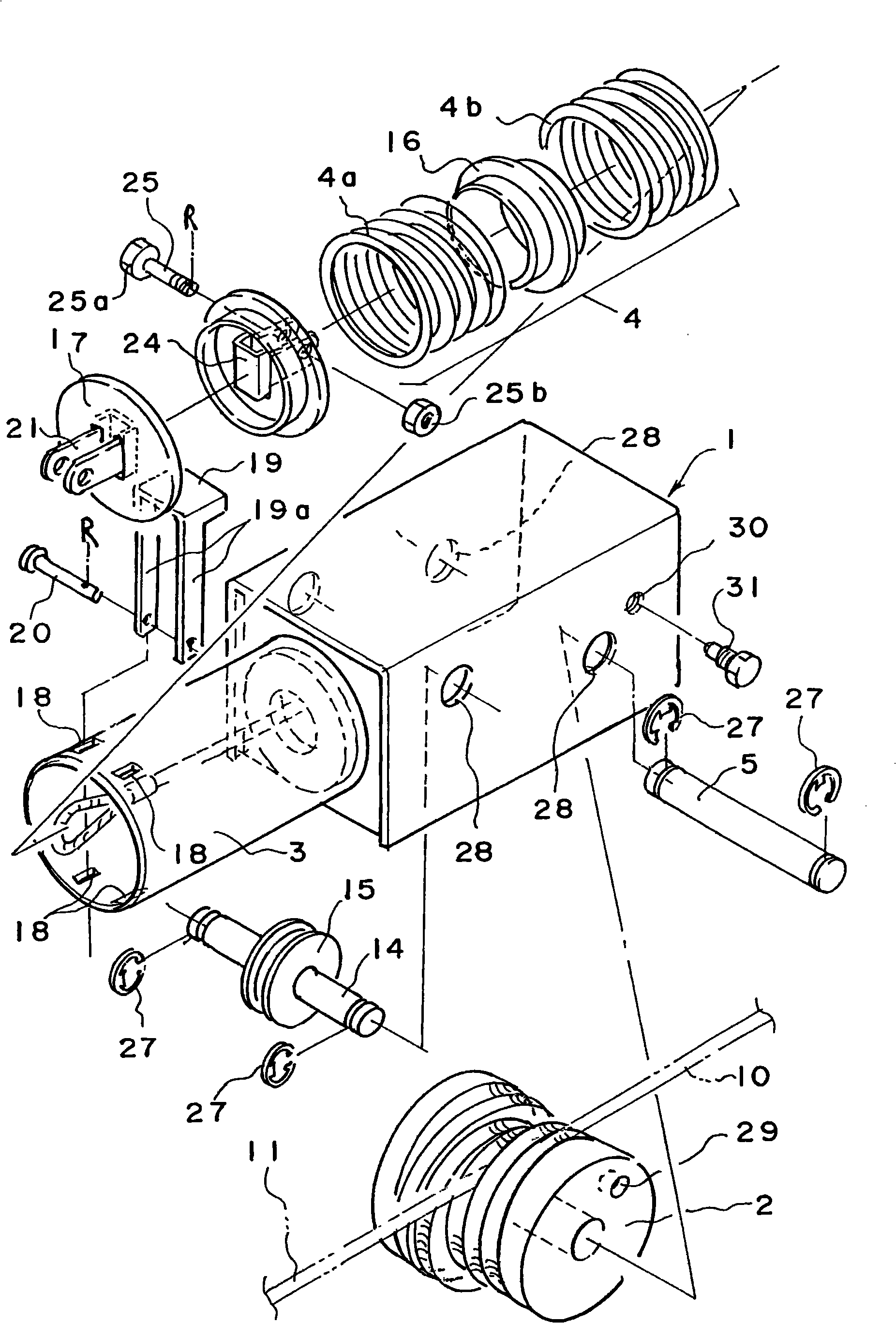

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0045] The tension balancer for trolley wires according to the present embodiment has a tension conversion pulley. Generally, the tension conversion pulley has a first pulley part having a helical first cable guide groove with a constant diameter and a first pulley part with a variable diameter in parallel. The second pulley part of the second cable guide groove is helically threaded, and the helical direction of the guide groove is opposite. In addition, a first cable is wound along the first cable guide groove, one end of which is fixed to a part of the first cable guide groove, and the other end is connected to the side of the overhead wire, and a second cable along the above-mentioned The guide groove is wound with a second cable whose one end is fixed to a part of the second cable guide groove and whose other end is attached to the axially moving member. In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com