Automatic tensile-force compensator of soft part

A technology of flexible parts and compensators, which is applied in the direction of adjusting/maintaining mechanical tension, instruments, non-electric variable control, etc., can solve the problems of potential energy element performance and parameter changes, affect the use effect, affect the work, etc., and achieve the protection of normal work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure and working principle of the embodiments of the automatic tension compensator for flexible parts will be described below in conjunction with the accompanying drawings.

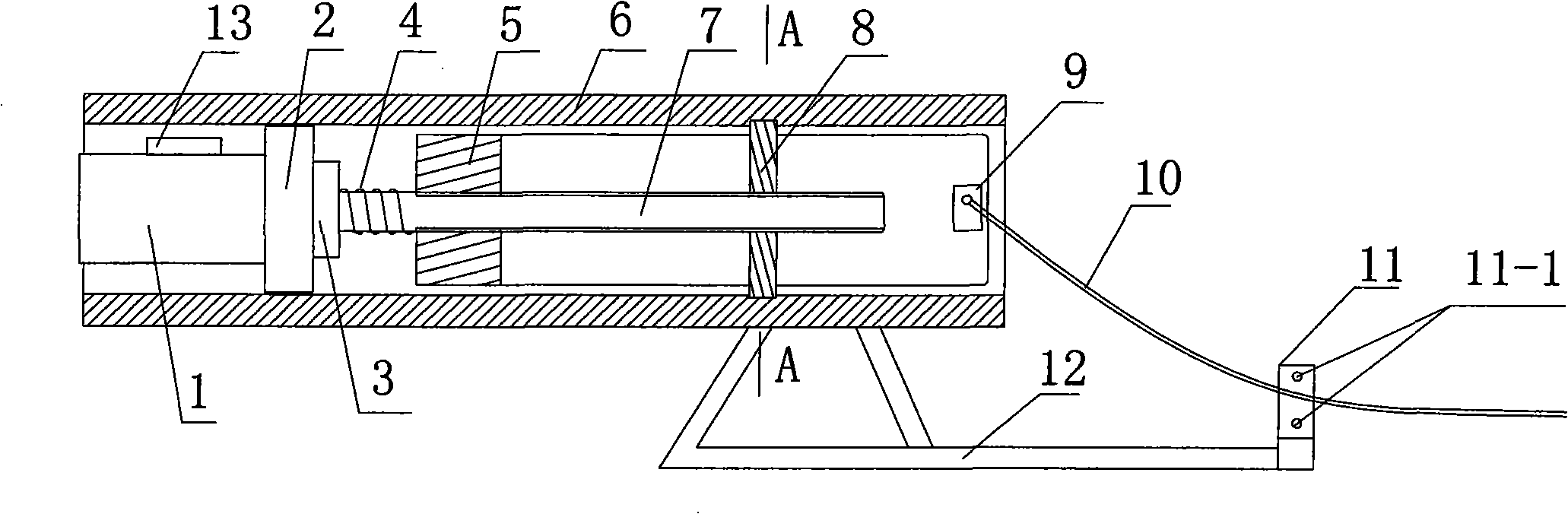

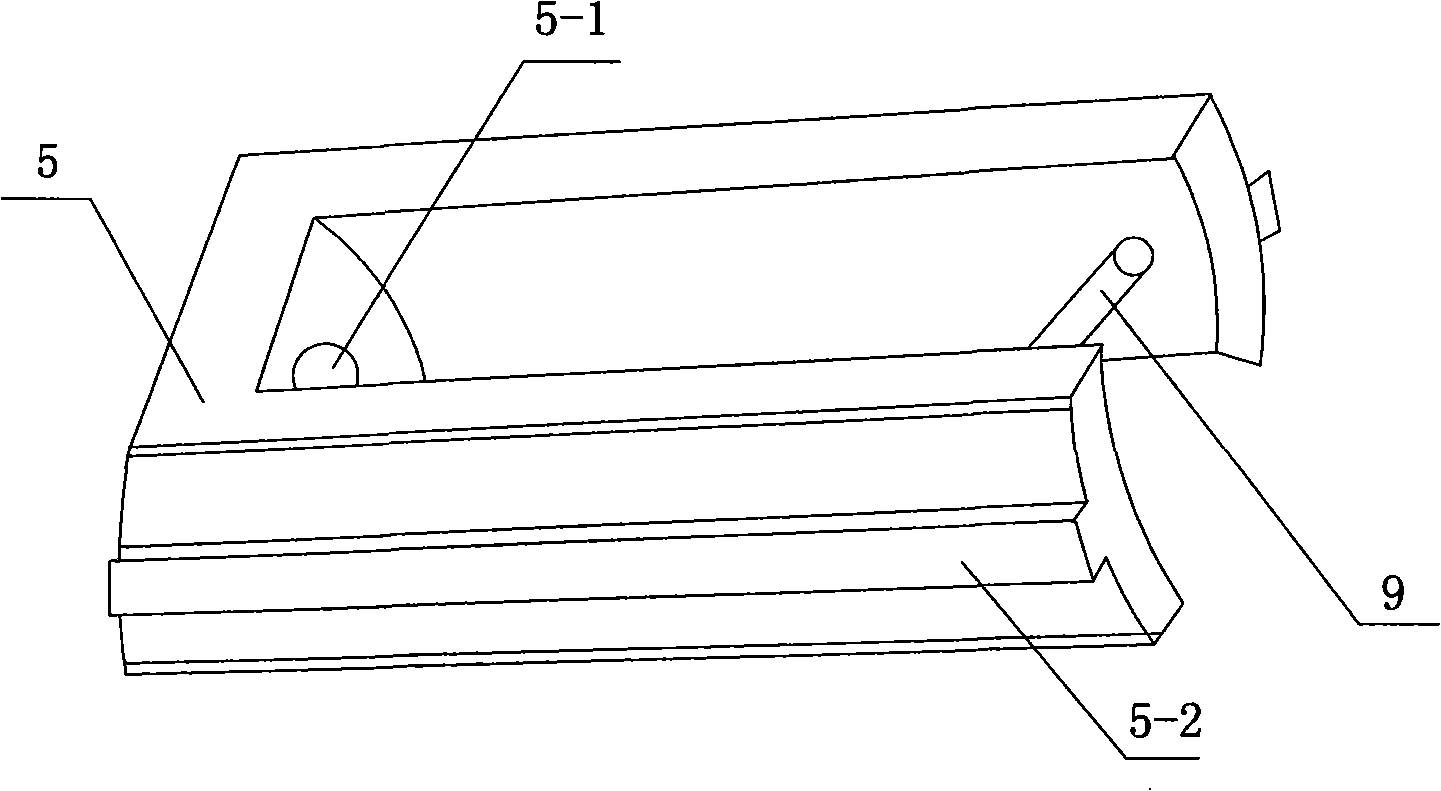

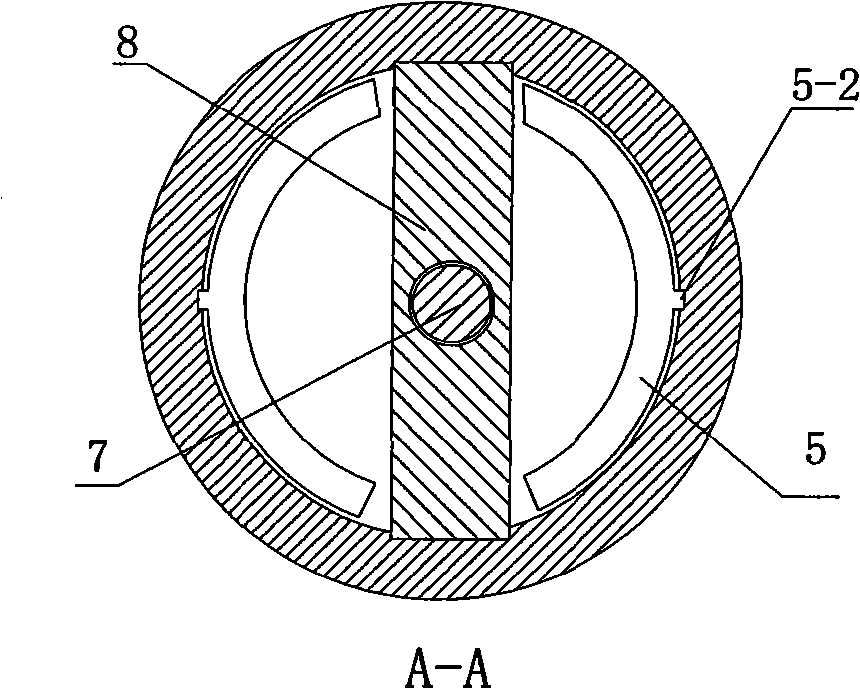

[0020] Such as figure 1 , in the automatic tension compensator for flexible parts, the motor 1 is provided with a controller 13, the screw rod 7 is connected with the motor 1 and the reducer 2, and is rotatable. Connection, the screw rod 3 between the U-shaped nut 5 and the reducer 2 is sleeved with a pressure sensor 3 and a spring 4; the three-dimensional structure of the U-shaped nut 5 (see figure 2 ), its outside is provided with convex rail 5-2, is fixed with insulating bar 9 between the two fork bars of U-shaped nut 5, is used for hanging cable 10 (being flexible part). U-shaped nut 5 is positioned in sleeve pipe 6, and its protruding rail 5-2 cooperates with the recessed rail of sleeve pipe 6 inboards (see image 3 ), the two form a concave-convex track, so that the U-shaped nut 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com