High-voltage DC cable insulating material and a preparation method thereof

A technology of cable insulation and high-voltage direct current, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., and can solve the problems that the suppression effect is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

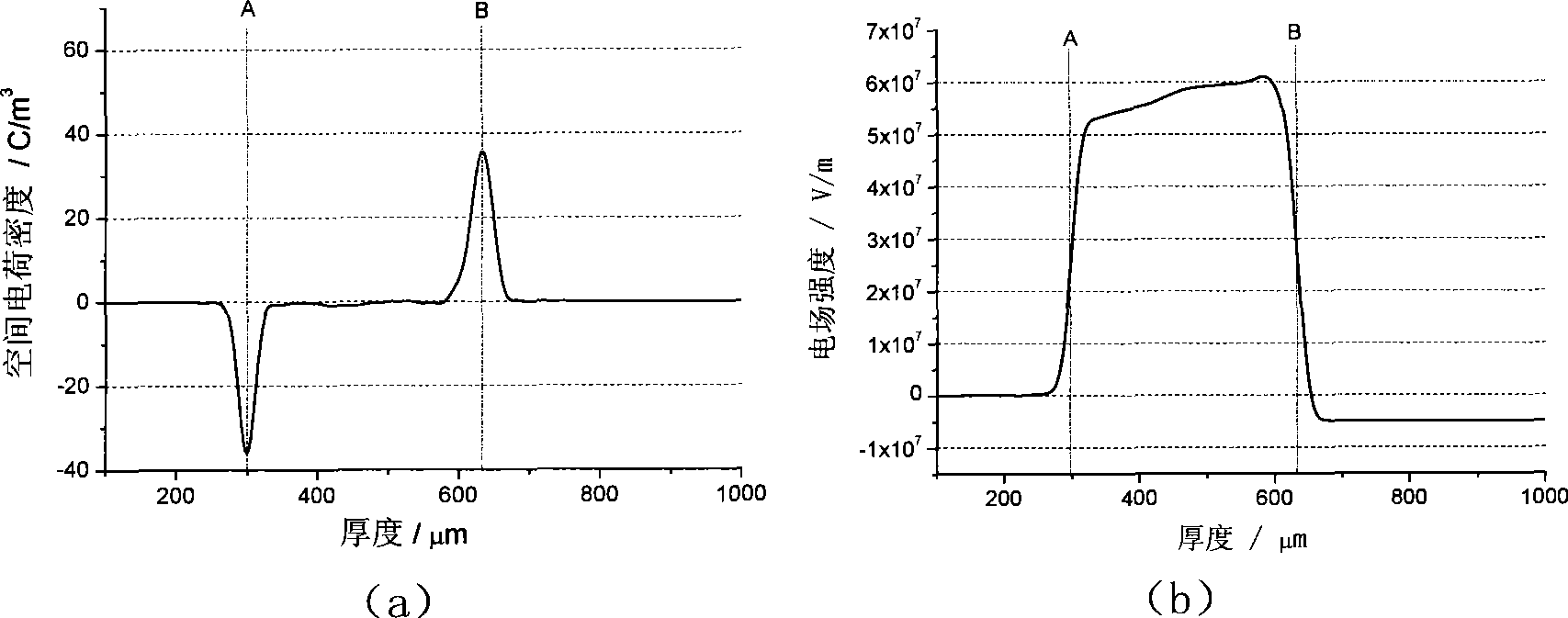

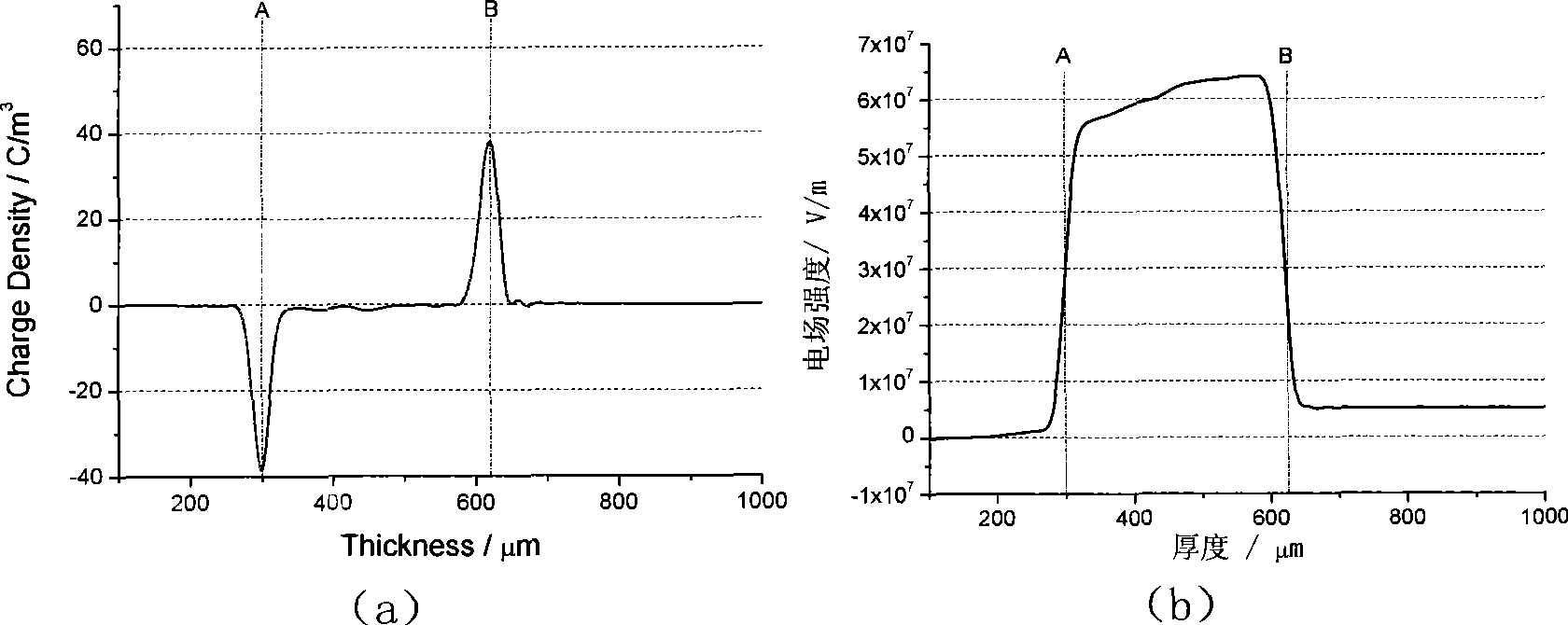

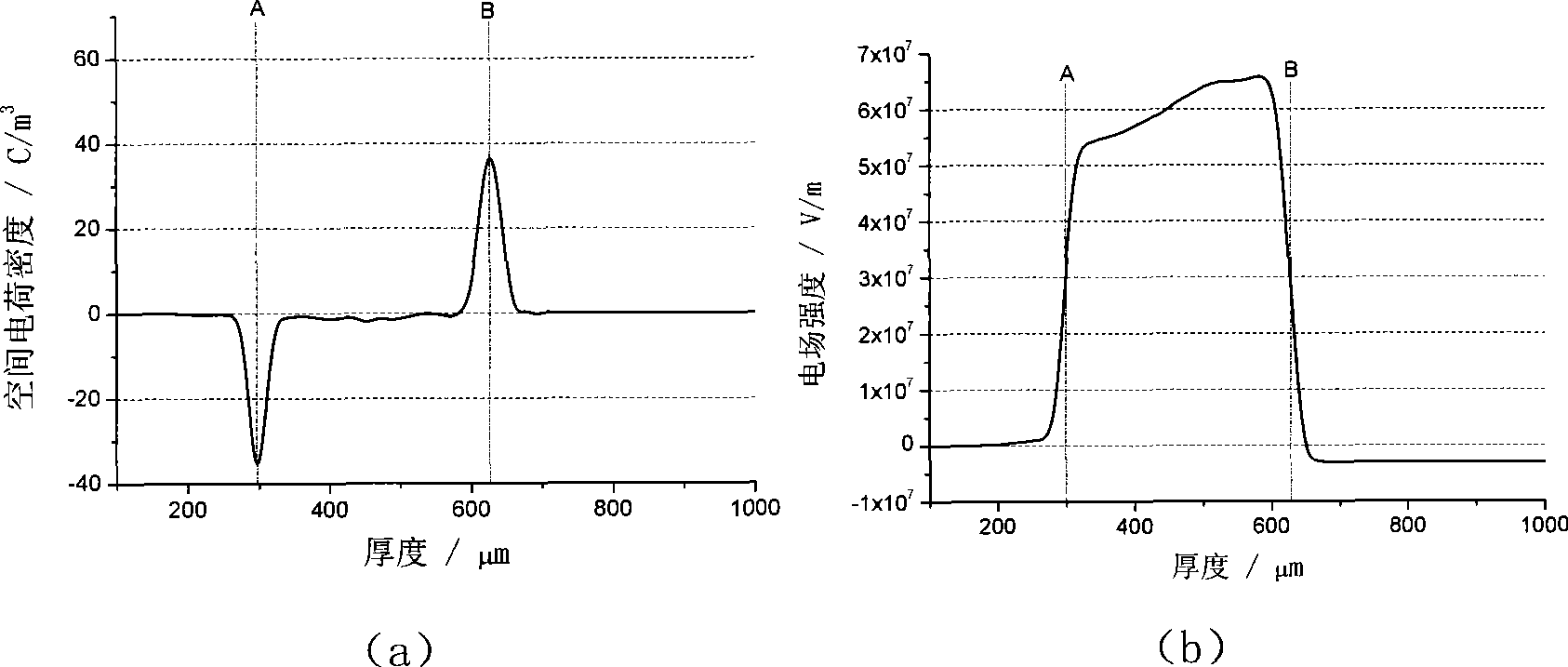

Image

Examples

Embodiment 1

[0020] Put 50 grams of low-density polyethylene, 0.05 grams of antioxidant 1010, 2.5 grams of aluminum oxide, and 0.5 grams of maleic anhydride into a Haake torque rheometer for mixing. The mixing temperature is 375K and the mixing time is After 10 minutes, 1.15 grams of dicumyl peroxide was put into a Huck torque rheometer and kneaded for 10 minutes. The kneading temperature was kept at 375K to obtain an insulating material that can be used for high-voltage plastic cables.

Embodiment 2

[0022] Put 50 grams of low-density polyethylene, 0.05 grams of antioxidant 1010, 1 gram of magnesium oxide, and 0.1 gram of maleic anhydride into a Haake torque rheometer and knead at a temperature of 378K for 15 minutes , and then put 1.15 grams of dicumyl peroxide into the Haake torque rheometer and knead for 15 minutes, and the kneading temperature was kept at 378K to obtain an insulating material that can be used for high-voltage plastic cables.

Embodiment 3

[0024] Put 50 grams of low-density polyethylene, 0.05 grams of antioxidant 1010, 0.25 grams of silicon oxide, and 2.5 grams of maleic anhydride into a Haake torque rheometer and knead at a temperature of 373K for 13 minutes , and then put 0.5 g of dicumyl peroxide into the Haake torque rheometer and kneaded for 13 minutes, and the kneading temperature was kept at 373K to obtain an insulating material that can be used for high-voltage plastic cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com