Quick high-flexibility manufacturing method for ceramic circuit board

A circuit board, fast technology, applied in the direction of printed circuit manufacturing, printed circuits, manufacturing tools, etc., can solve the problems of many processes, poor precision, low flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] 1) The ceramic material is made of 99% high-purity aluminum nitride ceramics, which are made into ceramic substrates by tape casting. The thickness is 0.1-2mm, the surface roughness Ra is 0.3-0.5μm, and the roughness can reach 0.03μm after polishing.

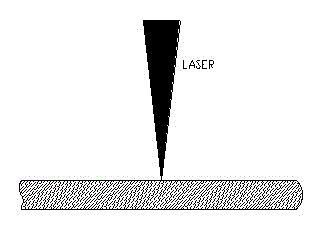

[0031] 2) Use ultraviolet 355nm nanosecond pulsed laser to drill and modify high-purity aluminum nitride ceramics. The laser source adopts ultraviolet 355nm nanosecond pulse laser, the maximum average laser output power is 10W, the pulse width is 1-10ns, and the pulse repetition frequency is 1-400kHz.

[0032] Laser drilling is preferably carried out with high power, high pulse repetition frequency, and high scanning speed. For example, if the average laser output power is 10W, the pulse repetition frequency is 100kHz, and the scanning speed is 100mm / s, fast drilling can be achieved, and the hole wall can also be laser modified. sex.

[0033] During laser surface modification, the energy density is controlled above the m...

example 2

[0038] 1) The ceramic material is 96% alumina ceramic, which is made into a three-dimensional ceramic matrix by casting method, and the surface roughness Ra is 0.3-0.5μm.

[0039]2) A picosecond pulsed laser with a center wavelength of 266nm is used to drill holes and modify the surface of alumina ceramics. The laser source adopts a picosecond pulse laser with a central wavelength of 266nm, the maximum average laser output power is 5W, the pulse width is 1-10ps, and the pulse repetition frequency is 100kHz-1MHz.

[0040] For laser drilling, when the average laser output power is 5W, the pulse repetition frequency is 1MHz, and the scanning speed is 50mm / s, the drilling is carried out in a focusing manner, and the focusing height decreases with the drilling depth, and multiple scans are performed until the drilling through or to the desired depth of the blind hole. Picosecond laser is an ultrashort pulse laser with short pulse width and high peak energy, which has great advanta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com