Dynamic testing method and system for wetting property

A technology for wetting performance and dynamic testing, used in measuring devices, instruments, scientific instruments, etc., can solve the problem that the total time required for wetting cannot be determined, the wetting performance and temperature cannot be measured, and the wetting performance and time cannot be measured. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

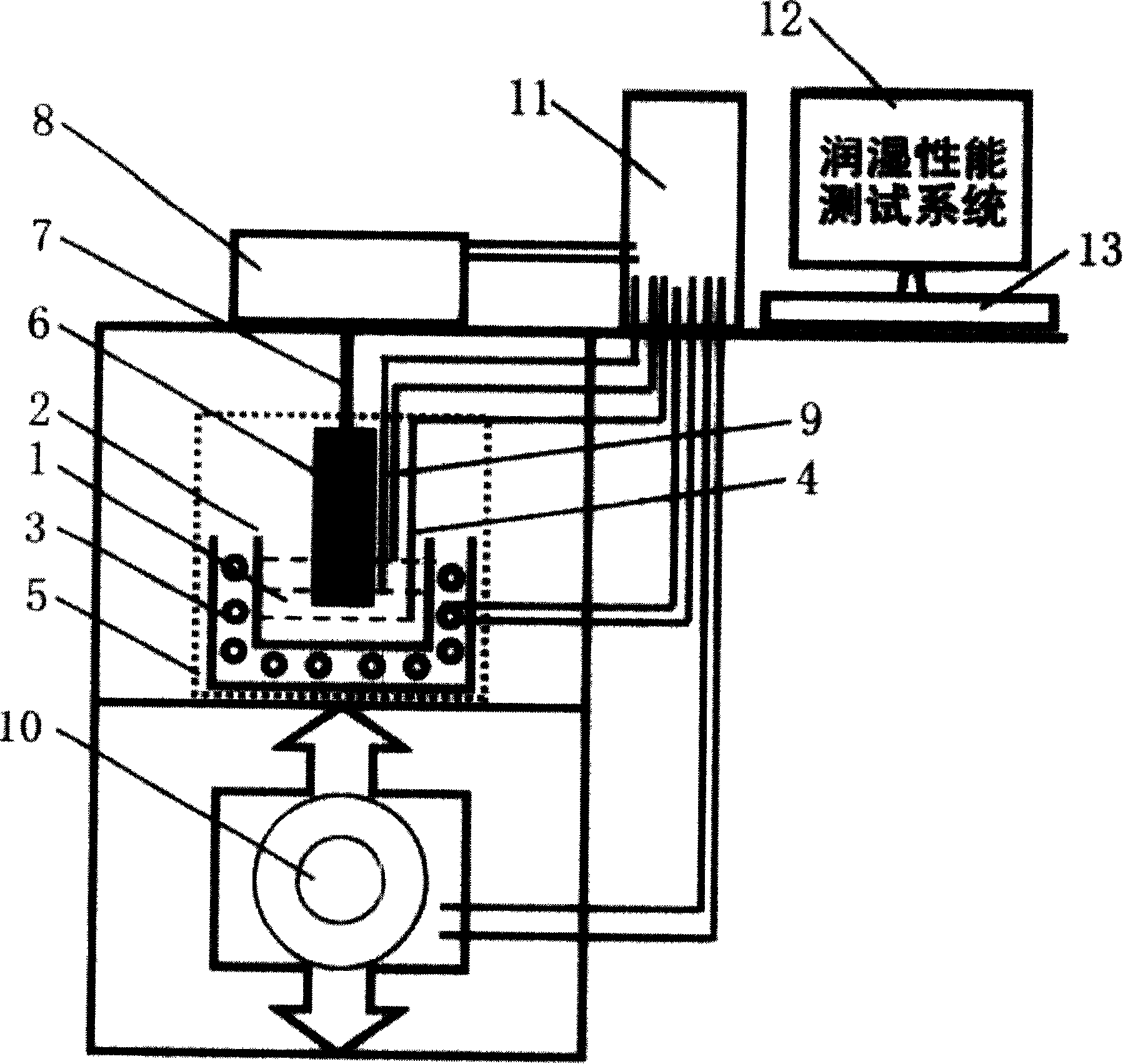

[0015] In the implementation system (device) shown in the drawings, the solder 1 is placed in the container 2, the heating system 3 heats and melts the solder 1, and the thermocouple 4 measures the temperature of the solder 1; metals, ceramics, composite materials 6, etc. pass through the suspension system 7 is connected to the force measuring balance 8; the height adjustment lifting system 10 adjusts the height of the molten solder to make it contact with the bottom of the material 6 to be welded such as metal, and the computer automatically starts to calculate the relationship curve of wetting force, wetting area and time at the moment of contact, Data collection and measurement, the trigger of automatic data collection is controlled by the solution height detection light trigger circuit; solder 1, container 2, heating system 3, thermocouple 4, etc. are passed through heat insulation box 5, force balance 8, and height adjustment lifting system 10 separated.

[0016] The inor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com