Automatic welding workpiece machine and dip soldering method

A dip soldering and automatic technology, applied in the direction of welding equipment, auxiliary devices, printed circuits, etc., can solve the second soldering operation of PCB boards that cannot be cut, and complete preheating, flux spraying, soldering, Problems such as foot cutting operation and low integration level of automatic tin dipping machine are achieved, and the effect of compact structure, high integration level and improved production efficiency is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

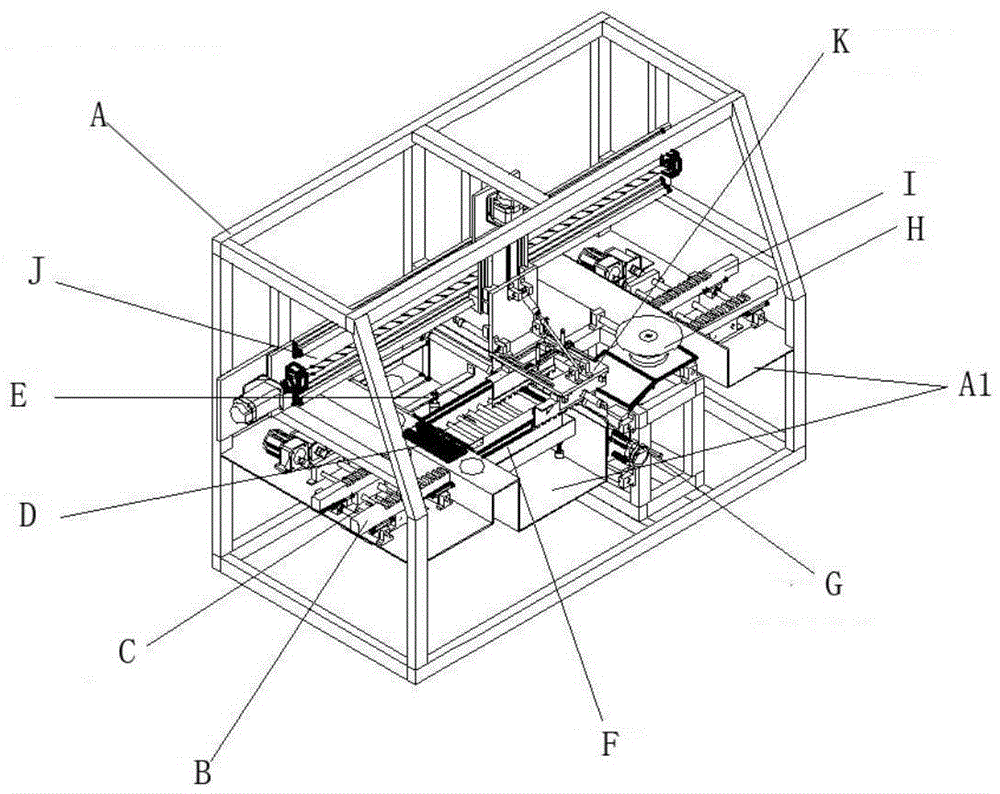

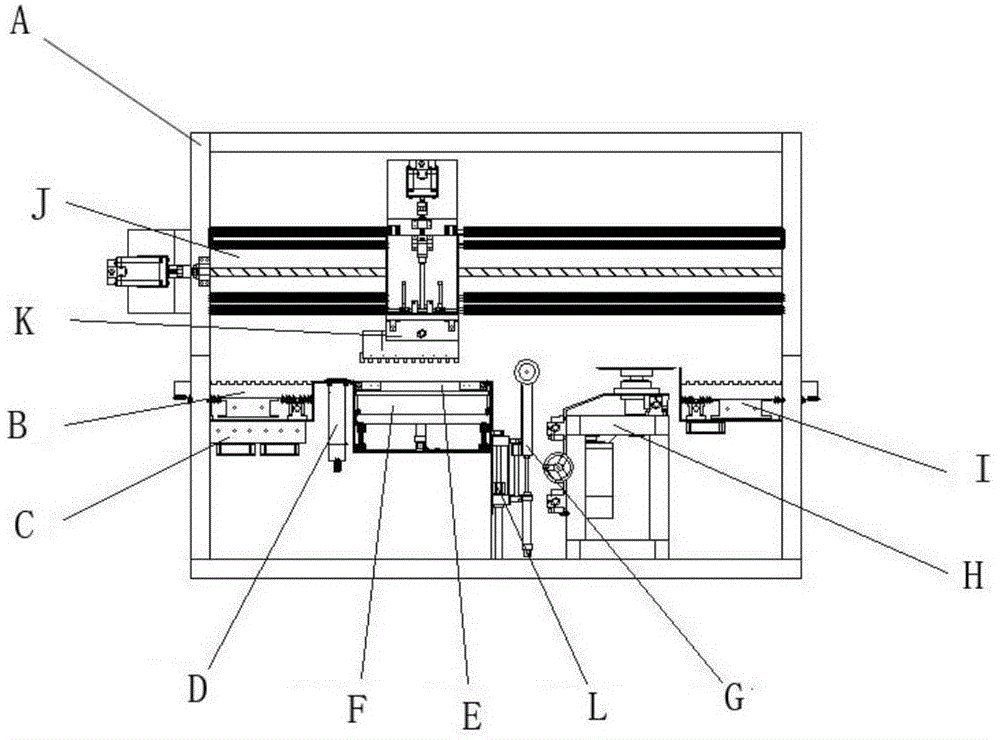

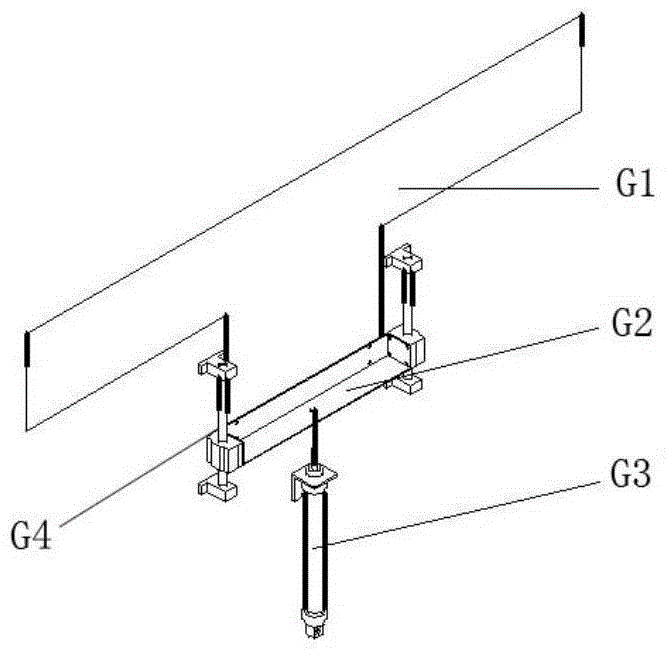

[0057] Such as figure 1 , 2 As shown, the present embodiment provides an automatic dip soldering machine, including: a support frame A with a running plane of the PCB board 10 inside, a board feeding mechanism B for sending the PCB board 10 into the running plane, and a board feeding mechanism B for sending the PCB board 10 into the running plane. 10 Preheating preheating mechanism C, spraying mechanism D for spraying flux to the PCB 10, tin furnace mechanism F for containing solder liquid, used for inserting the preheated PCB 10 into the tin furnace at a certain angle Mechanism F for clamping and dipping soldering mechanism K for soldering, used for scraping off the tin oxide surface layer in tin furnace mechanism F before PCB board 10 is soldered, and scraping mechanism E for making PCB board 10 leave the running plane after soldering Board ejection mechanism I, and the transmission mechanism J that can do reciprocating motion above the described operating plane and is used...

Embodiment 2

[0109] This embodiment provides a dip soldering method, using the dip soldering machine as described in Embodiment 1, comprising the following steps:

[0110] S1: The PCB board is transported to the running plane through the board feeding mechanism B, the PCB board is clamped by the clamping and dipping mechanism K, and the clamping and dipping mechanism K is driven by the transmission mechanism J to transport the PCB board to the working place where the preheating mechanism C is located. bit;

[0111] S2: Preheat the PCB board through the preheating mechanism C;

[0112] S3: Transport the PCB board to the station where the spray mechanism D is located through the transmission mechanism J, and spray flux through the spray mechanism D;

[0113] S4: Transport the PCB board to the station where the tin furnace mechanism F is located through the transmission mechanism J, start the tin scraping mechanism E to scrape off the tin oxide surface layer in the tin furnace mechanism F, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com