Epoxy resin composition as well as prepreg and metal-foil-clad laminated board manufactured by using same

A technology of epoxy resin and prepreg, which is applied in the direction of metal layered products, synthetic resin layered products, layered products, etc. It can solve the problems of unsuitable printed circuit boards, low glass transition temperature, and low toughness of copper clad laminates. , to achieve the effect of improving the reliability of the through hole, excellent toughness and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Use EPON828 bisphenol A epoxy resin 70 parts, polybutadiene epoxy resin 3 parts, E100 aromatic amine 20 parts, polybutadiene maleic anhydride 7 parts, silicon micropowder 15 parts, flame retardant brominated styrene 20 parts Parts and supplemented with catalyst 2-PI, use MEK to dissolve the above compounds, and prepare a glue with a suitable viscosity. Use 7628 type electronic grade glass cloth to soak the glue, and bake in an oven at 155°C to remove the solvent to obtain a B-stage prepreg.

[0048] Laminate eight prepregs and two one-ounce electrolytic copper foils together, and laminate them with a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are as follows: 1. When the material temperature is 80-120°C, the heating rate is controlled at 1.0-3.0°C / min; 2. The pressure is set at 20kg / cm 2 ; 3. The curing temperature is 190°C, and keep this temperature for 90 minutes. The corresponding properties are shown in Table 1 and Table 2. ...

Embodiment 2

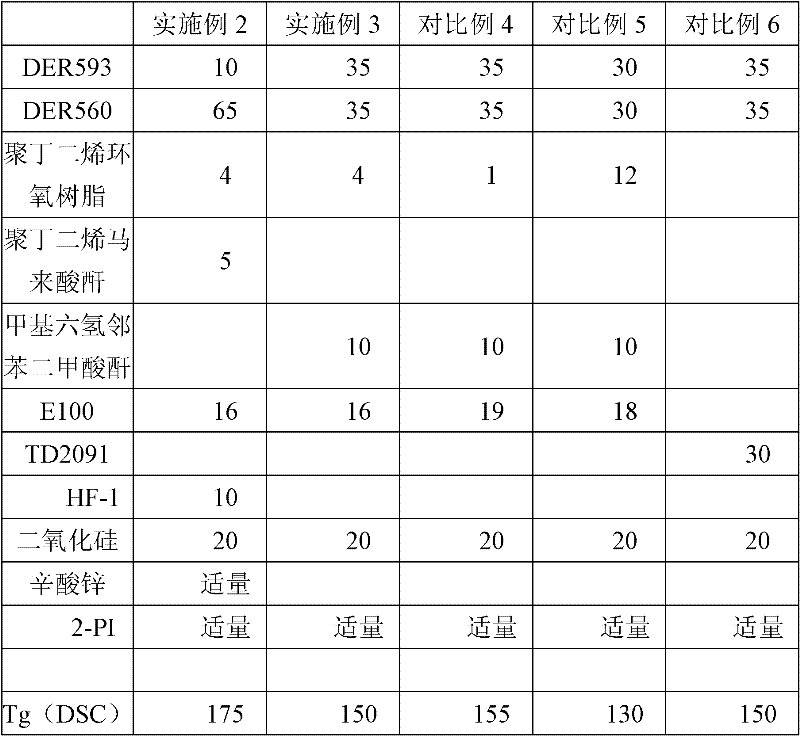

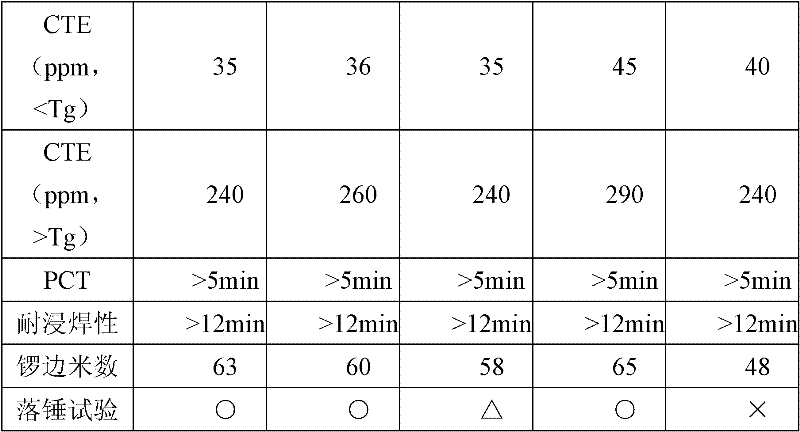

[0063] Use 10 parts of DER593 epoxy resin, 65 parts of DER560 brominated epoxy resin, 4 parts of polybutadiene epoxy resin, 5 parts of polybutadiene maleic anhydride, 16 parts of E100 aromatic amine, 10 parts of HF-1 cyanate parts, 20 parts of silicon micropowder, supplemented with catalyst zinc octoate and 2-PI, use MEK to dissolve the above compounds, and prepare a glue with a suitable viscosity. Use 7628 type electronic grade glass cloth to soak the glue, and bake in an oven at 155°C to remove the solvent to obtain a B-stage prepreg.

[0064] Laminate eight prepregs and two one-ounce electrolytic copper foils together, and laminate them with a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are as follows: 1. When the material temperature is 80-120°C, the heating rate is controlled at 1.0-3.0°C / min; 2. The pressure is set at 20kg / cm 2 ; 3. The curing temperature is 190 degrees, and keep this temperature for 90 minutes. The corresponding ...

Embodiment 3

[0066] Use 35 parts of DER593 epoxy resin, 35 parts of DER560 brominated epoxy resin, 4 parts of polybutadiene epoxy resin, 10 parts of methyl hexahydrophthalic anhydride, 16 parts of E100 aromatic amine, 20 parts of silicon micropowder, With the aid of catalyst 2-PI, MEK is used to dissolve the above compounds and prepare a glue with a suitable viscosity. Use 7628 type electronic grade glass cloth to soak the glue, and bake in an oven at 155°C to remove the solvent to obtain a B-stage prepreg.

[0067] Laminate eight prepregs and two one-ounce electrolytic copper foils together, and laminate them with a hot press to obtain a double-sided copper-clad laminate. Lamination conditions were the same as in Example 2. The corresponding properties are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com