Thermoplastic polyimide material and method for preparing flexible copper clad laminate through using material

A technology of polyimide and polyimide powder, which is applied in the direction of circuit substrate materials, chemical instruments and methods, lamination, etc., and can solve problems such as difficult to achieve double-sided panel manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

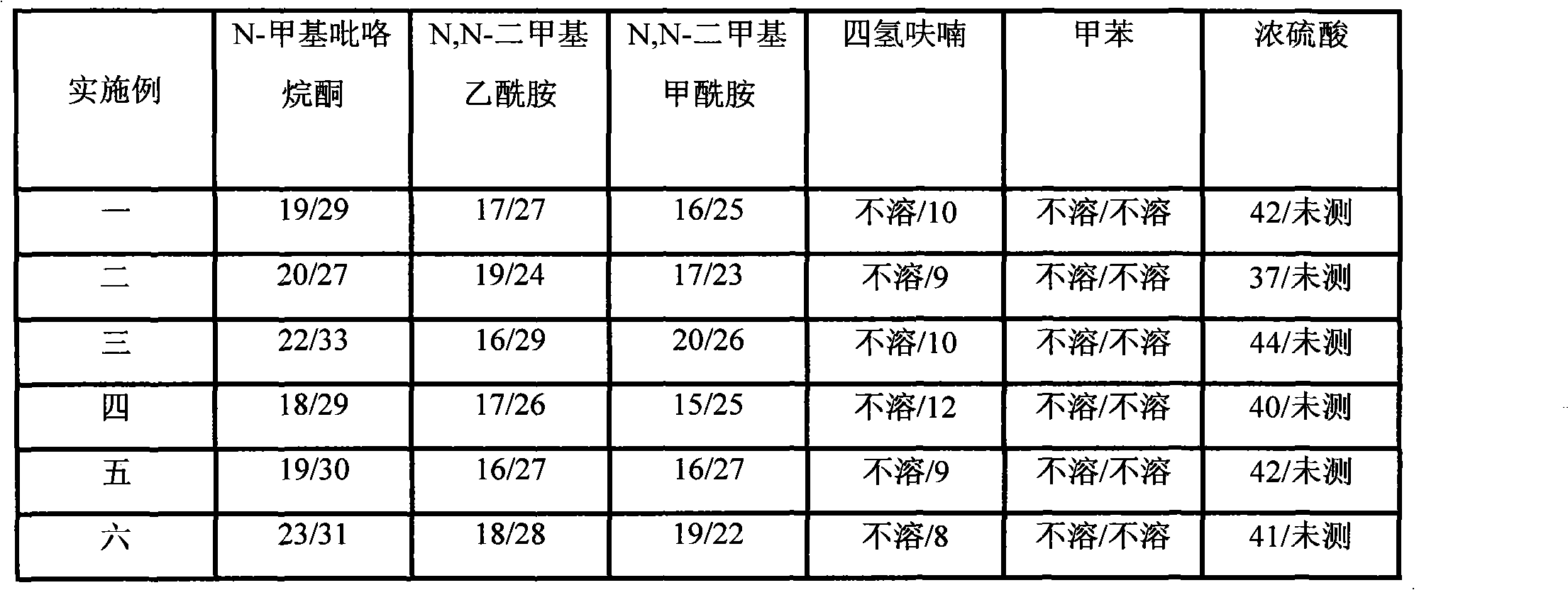

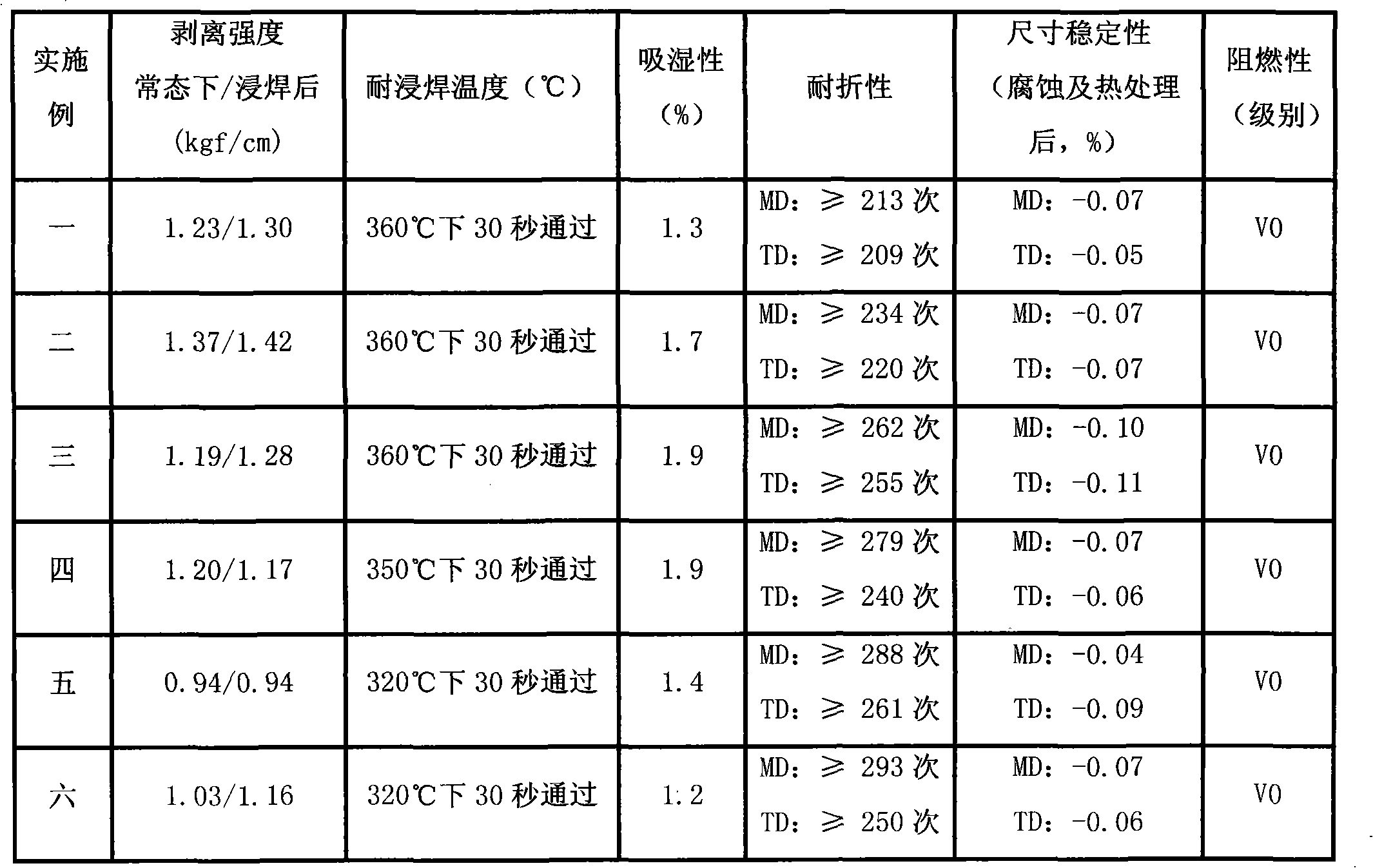

Examples

Embodiment 1

[0012] In a reactor with reflux and nitrogen gas, 0.40mol of 4-ethoxybiphenol-3,5-diaminobenzoate, 0.20mol of 2,2-bis(4-aminophenyl)hexa Fluoropropane, 0.40mol of 1,3-bis(4-aminophenoxy)benzene was stirred at 40°C and dissolved in N-methylpyrrolidone. After complete dissolution, the reaction temperature was lowered to 0°C, and then 1.03 mol of 3,3,4,4-benzophenone tetracarboxylic dianhydride was added in 5 portions within 1 hour. After the addition of the dianhydride monomer, the reaction was carried out at a constant temperature for 12 hours to obtain a polyamic acid copolymer solution. Heat this solution to 50°C, add 1.5L of a mixture of 2,2-bipyridine and acetic anhydride with a volume ratio of 1:3, stir for 20 hours, then pour this solution into deionized water to precipitate, filter, and then use ethanol After washing, the obtained product was vacuum-dried at 100° C. for 12 hours to finally obtain TPI powder.

[0013] Dissolve this TPI powder in a mixed solvent of aceto...

Embodiment 2

[0015] In a reactor with reflux and nitrogen gas, 0.50mol of 4-ethoxybiphenol-3,5-diaminobenzoate, 0.25mol of 2,2-bis(4-aminophenyl)hexa Fluoropropane, 0.25mol of 1,3-bis(4-aminophenoxy)benzene was stirred at a constant temperature of 40°C, dissolved in N,N-dimethylacetamide, and after complete dissolution, the reaction temperature was lowered to 0 0.62 mol of 3,3,4,4-benzophenone tetracarboxylic dianhydride and 0.40 mol of pyromellitic dianhydride were added in 5 portions within 1 hour. After the dianhydride monomer was added, the reaction was carried out at a constant temperature for 14 hours to obtain a polyamic acid copolymer solution. Heat this solution to 50°C, add 1.5L of a mixture of 2,2-bipyridine and acetic anhydride with a volume ratio of 1:3, stir for 20 hours, then pour this solution into deionized water to precipitate, filter, and then use ethanol After washing, the obtained product was vacuum-dried at 100° C. for 12 hours to finally obtain TPI powder.

[0016]...

Embodiment 3

[0018]In a reactor with reflux and nitrogen gas, 0.40mol of 4-ethoxybiphenol-3,5-diaminobenzoate, 0.20mol of 2,2-bis(4-aminophenyl)hexa Fluoropropane, 0.20mol of 1,3-bis(4-aminophenoxy)benzene and 0.20mol of 4,4'-diaminodiphenyl ether were stirred at 40°C and dissolved in acetone with a volume ratio of 1:3 and N-methylpyrrolidone in a mixed solvent, after completely dissolving, lower the reaction temperature to 0°C, and then add 0.50mol of 3,3,4,4-benzophenone tetracarboxylic acid in 5 times within 1 hour dianhydride and 0.52 mol of triphenyl ether tetracarboxylic dianhydride of tribenzoic acid. After the addition of the dianhydride monomer, react at a constant temperature for 15 hours to obtain a polyamic acid copolymer solution. Heat this solution to 50°C, add 1.5L of a mixture of 2,2-bipyridine and acetic anhydride with a volume ratio of 1:3, stir for 20 hours, then pour this solution into deionized water to precipitate, filter, and then use ethanol After washing, the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com