High-performance thermally-conductive and insulating film for aluminum-based copper-clad laminate, and preparation method thereof

A technology of aluminum-based copper clad and insulating adhesive film, which is applied in the direction of adhesives, epoxy resin adhesives, polymer adhesive additives, etc., can solve the problem of poor thermal expansion coefficient matching and bonding performance, poor thermal conductivity of aluminum substrates, and thermal conductivity. Low-level problems, to achieve the effect of improving heat resistance and anti-peel strength, high peel strength, and solving the problem of glue flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

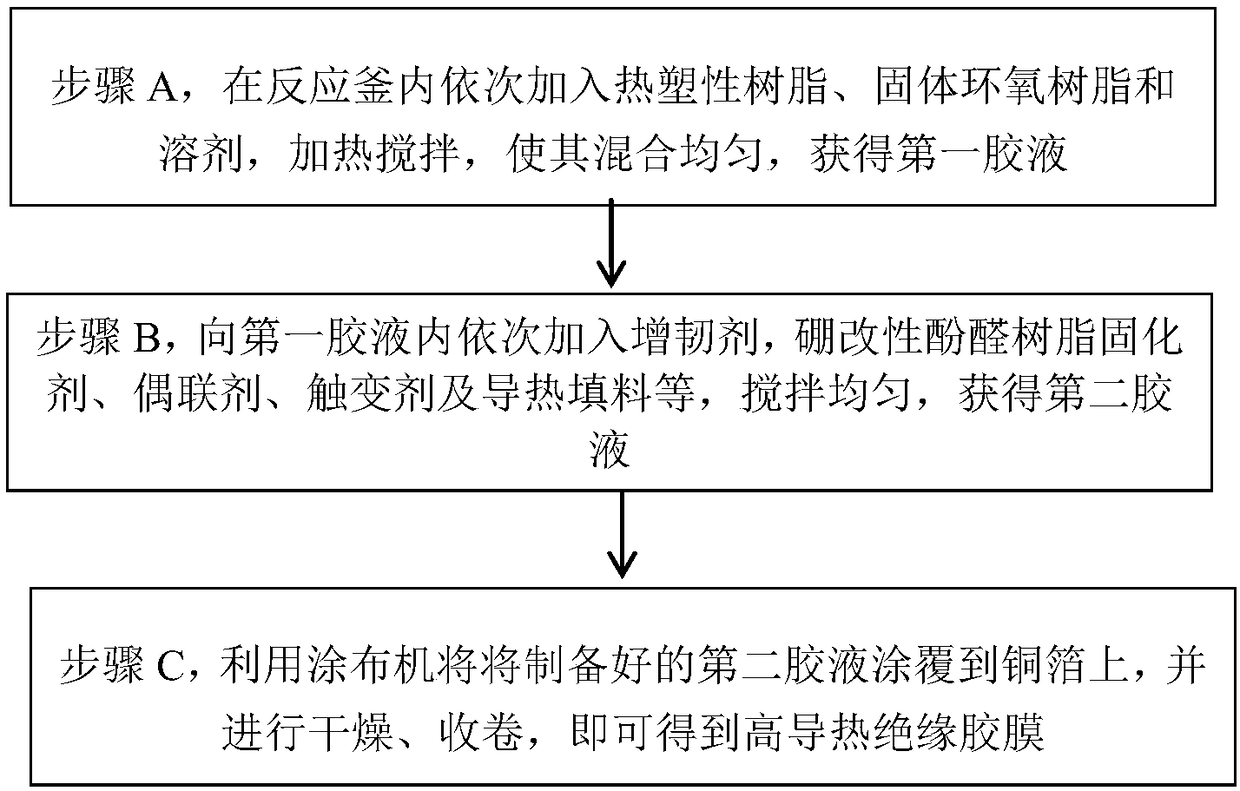

Method used

Image

Examples

Embodiment 1

[0022] A, take by weighing 6 parts of solid epoxy resin E12, 3 parts of styrene-bismaleic anhydride graft copolymers (Mn=2000), 30 parts of mixed solvents (toluene, methyl ethyl ketone, butanol volume ratio are 4:4 : 1); put into the reaction kettle and heat to 60°C, and stir to make it dissolve completely to obtain the first glue solution.

[0023] B. Add 1.8 parts of carboxy-modified liquid nitrile rubber, 6 parts of boron-modified phenolic resin curing agent (boric acid / hydroquinone / formaldehyde co-reaction product, Mn=2400), 1.5 parts of KH in the first glue solution -560 parts of silane coupling agent, 1.2 parts of fumed silica (R792), 80 parts of spherical alumina (5 μm), 40 parts of quartz powder (2 μm); stir well to obtain the second glue.

[0024] C. Use the coating machine to coat the prepared second glue solution on the copper foil, and dry and roll it to obtain a high thermal conductivity insulating glue film (film thickness: 200 μm, thermal conductivity: 1.79W / ( ...

Embodiment 2

[0026] A, take by weighing 10 parts of solid epoxy resin E12, 3 parts of epoxy modified acrylate (Mn=80000), 50 parts of mixed solvent (toluene, methyl ethyl ketone, butanol volume ratio is 4:4:1); add Heat the reaction kettle to 60° C. and stir to dissolve completely to obtain the first glue solution for use.

[0027] B. Add 2.0 parts of polybutadiene rubber, 5 parts of boron-modified phenolic resin curing agent (boric acid / resorcinol / formaldehyde co-reaction product, Mn=1600), 1.0 parts of KH-550 to the first glue solution Silane coupling agent, 2.0 parts of fumed silica (R792), 73 parts of spherical alumina (5 μm), 23 parts of spherical alumina (500 nm); stir evenly to obtain the second glue.

[0028] C. Use the coating machine to coat the prepared second glue solution on the copper foil, and dry and roll it to obtain a high thermal conductivity insulating film (film thickness: 200 μm, thermal conductivity: 2.01W / ( m K), peel strength: 1.58N / mm, breakdown voltage: 6.1kV, t...

Embodiment 3

[0030] A, take by weighing 5 parts of solid epoxy resin E20, 3.2 parts of phenoxy resin (Mn=50000), 50 parts of mixed solvent (N, N-dimethylformamide, butanone, ethyl acetate volume ratio is 4: 4:2); put it into the reaction kettle and heat it to 60°C, and stir to dissolve it completely to obtain the first glue.

[0031] B. Add 1.8 parts of core-shell structure organosilicon / acrylate toughening agent and 7 parts of boron-modified phenolic resin curing agent (co-reaction product of phenylboronic acid / hydroquinone / formaldehyde, Mn=1800) in the first glue solution ), 1.0 parts of KH-672 silane coupling agent, 2.0 parts of fumed silica (R792, 80 parts of spherical alumina (10 μm), 20 parts of boron nitride (300 nm); stir evenly to obtain the second glue.

[0032] C. Use the coating machine to coat the prepared second glue solution on the copper foil, and dry and roll it to obtain a high thermal conductivity insulating glue film (film thickness: 200 μm, thermal conductivity: 2.52W / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com