Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga

A sn-cu-ni, lead-free solder technology, applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., to achieve excellent mechanical properties, improved oxidation resistance and creep resistance, wettability good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

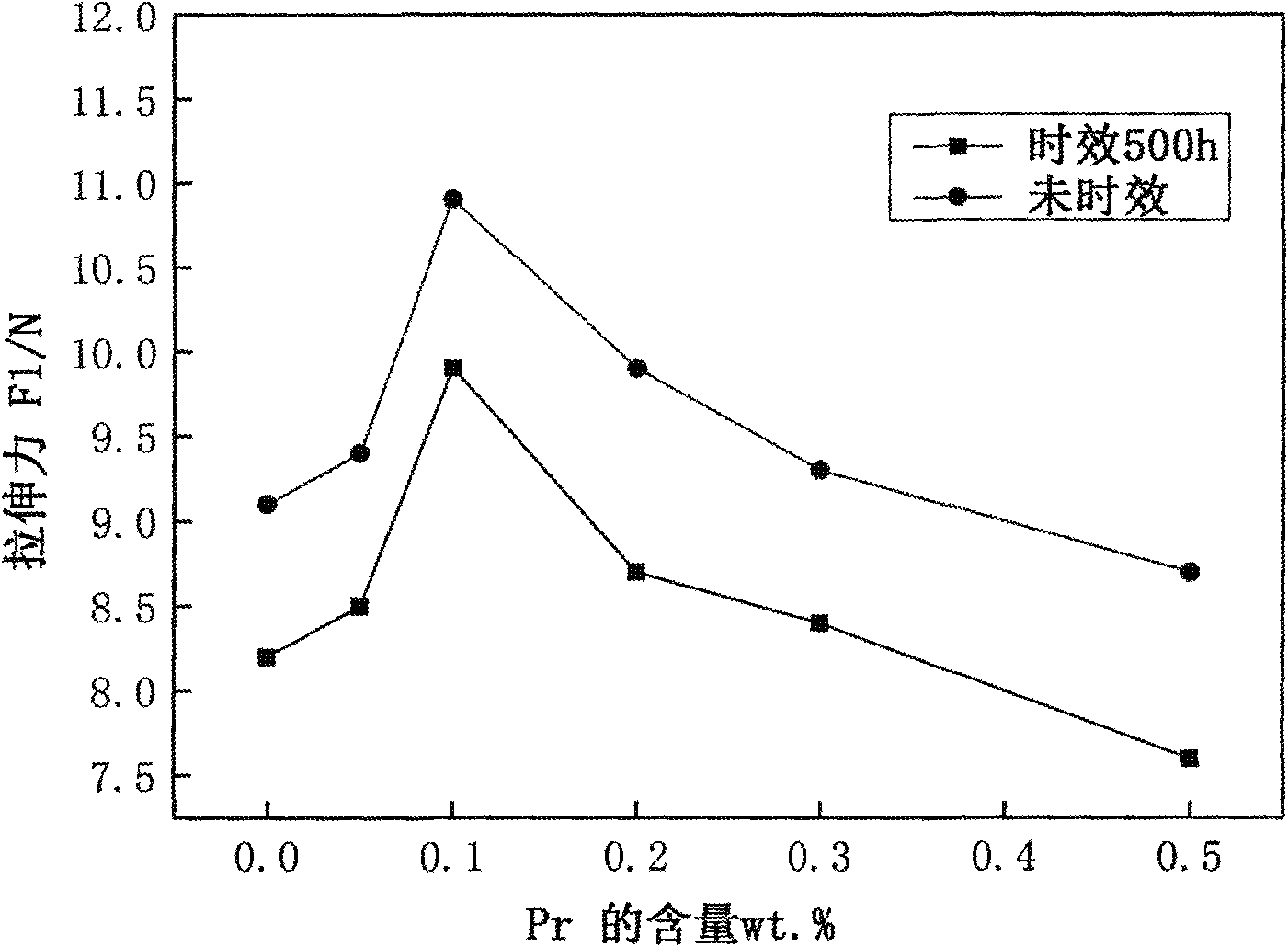

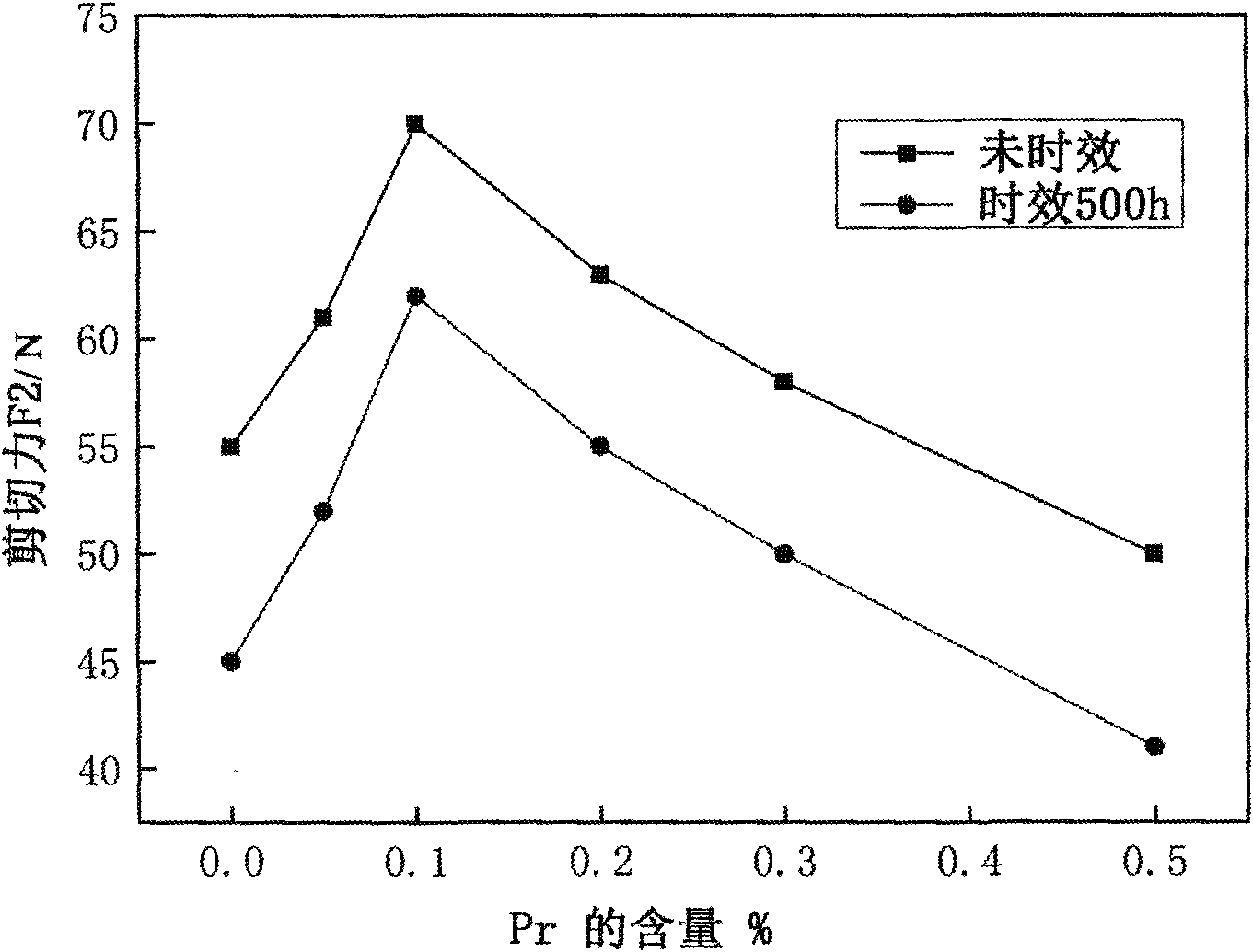

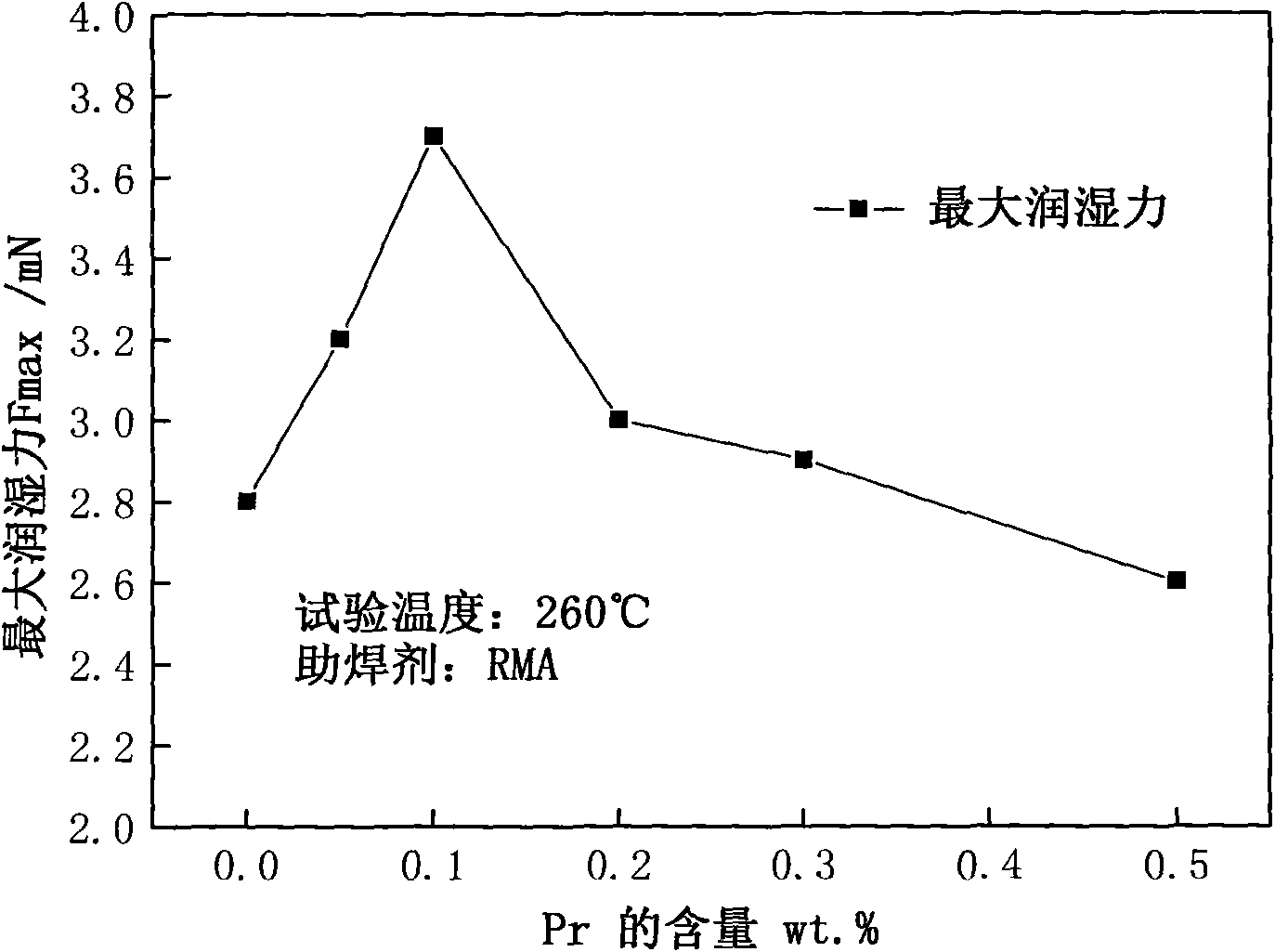

[0045] A Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga, proportioned by mass percentage, its composition is: 0.07% Cu, 1.5% Ni, 0.001% Pr, 0.03% Sr, 0.01% Ga, 0.001 %Pb, the balance is Sn. The solidus temperature of the "Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga" obtained by the above composition ratio is about 220°C, and the liquidus temperature is about 227°C (experimental error is considered). The wetting balance method was used to test the wetting performance of the solder on the copper plate. The maximum wetting force was 2.9mN, the wetting time was 0.72s, and the wetting and spreading effect was excellent. The tensile force of the QFP solder joint is 9.1N, the shear strength of the chip resistor is 60N, and the creep fatigue life of the solder joint is 145h.

Embodiment 2

[0047]A Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga, proportioned by mass percentage, its composition is:, 2.5% Cu, 0.01% Ni, 0.05% Pr, 0.05% Sr, 0.05% Ga, 0.05% Pb, the balance is Sn. The solidus temperature of the "Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga" obtained by the above composition ratio is about 217°C, and the liquidus temperature is about 225°C (experimental error is considered). The wetting balance method was used to test the wetting performance of the solder on the copper plate. The maximum wetting force was 3.2mN, and the wetting time was 0.58s. The wetting and spreading effect was excellent. The tensile force of the QFP solder joint is 9.4N, the shear strength of the chip resistor is 62N, and the creep fatigue life of the solder joint is 162h.

Embodiment 3

[0049] A Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga, proportioned by mass percentage, its composition is: 0.5% Cu, 0.06% Ni, 0.001% Pr, 0.1% Sr, 0.001% Ga, 0.05 %Pb, the balance is Sn. The solidus temperature of the "Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga" obtained by the above composition ratio is about 219°C, and the liquidus temperature is about 227°C (experimental error is considered). The wetting balance method was used to test the wetting performance of the solder on the copper plate. The maximum wetting force was 3.4mN, the wetting time was 0.69s, and the wetting and spreading effect was excellent. The tensile force of the QFP solder joint is 9.3N, the shear strength of the chip resistor is 57N, and the creep fatigue life of the solder joint is 147h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretching force | aaaaa | aaaaa |

| stretching force | aaaaa | aaaaa |

| stretching force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com